Date: 10 October 2012

The range is available in many openings for a perfect regulation of the light. Mesh openings from 1000 to 25 micron with open light passage from 25 to 60% and thickness from 1000 to 70 micron.

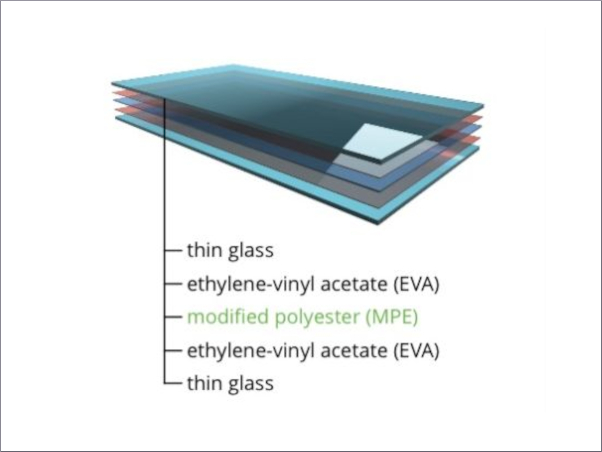

ARQUIFIL mesh and fabrics have a very high dimensional stability, and a hydrophobic - treated surface prepared to receive the interlayers used in glass lamination. They are more transparent and lighter (about 50% less) then a corresponding metal fabric, they do not need to be cleaned or treated before the lamination.

ARQUIFIL range comprises of one or two sides products and each of the metals used gives the mesh and fabrics a specific colour, enabling an high diversification and an excellent aesthetic result.

ARQUIFIL products are extremely flexible, easy to use in production , and have a very high adhesion to the plastic interlayers with an high reduction of the delamination risks. They are the state of the art tool for architectural planning and glass companies.

ARQUIFIL Range: ARQUIFIL AL (aluminum), ARQUIFIL CU (copper), ARQUIFIL BR (bronze), ARQUIFIL TI (titanium), ARQUIFIL CR (chrome), ARQUIFIL INOX.

ARQUIFIL AL (aluminum) .jpg)

ARQUIFIL BR (bronze)

ARQUIFIL (plug ethnic)

Decorative finishing:

ARQUIFIL G: embossed surface treatment. Proprietary or custom designs.

ARQUIFIL D: custom decorated surface treatment

ARQUIFIL L: laser engraved/etching surface treatment

ARQUIFIL S: crease surface treatment

ARQUIFIL P: pleating surface treatment

Syntarqui Sas di Coira Fabrizia & C. Via Cervino 6d -21050 GORLA MAGGIORE (VA), Italia, Tel +39 (0)331 618603 - +39 3404918092 info@syntarqui.com www.syntarqui.com

Add new comment