First presented at GPD 2019

The option of regulating internal and external conditions acquires great relevance in new approaches to sustainable building solutions. Studies on climate adaptive façades show a very high potential for improved indoor environmental quality conditions and energy savings by moveable façades.

A number of movable façades were realized in the past, but the use of thin glass with a thickness of 0.5 mm to 2 mm opens a brand-new field, that allows for playing with the geometry of the outer skin and the opportunity to make it adaptive by movement.

Thin glass requires for curved surfaces in order to gain structural stiffness in static use. In kinetic façades the high flexibility of thin glass allows for new options for changes in size and position by bending of elements rather than implementing hinges in a system of foldable rigid panels.

The geometry is based on the known theory of developable surfaces for keeping a low stress-level during movement. Façades may therefore be created from cold bent or curved laminated thin glass layers which provide better sealing, greater simplicity in construction, robustness and durability of moveable components which may be actuated or move autonomously.

By application of the principles of conventional moveable façades to bendable geometries a new toolset may be provided for the design process by architects and will be explained by design examples in this paper. Some concepts based on the before mentioned theories were created to explain principles and discuss their applicability.

Introduction

2016 a research centre, “Josef Ressel Centre for Thin Glass Technology for Structural Glass Applications”, was launched and deals, for example, with the topics of the determination of the ultimate bending strength of thin glass, explores new fields of applications for thin glass or creates new design possibilities for architects.

Another aim of this research centre is to systematically gather existing knowledge about general moveable structures in buildings and apply this expertise to façades made from thin glass as for example climate adaptive building shells. Based on experiences with prototypes both at model scale and real size, computer models were carried out and tested in terms of kinematics of bending using Rhinoceros 3D with Grasshopper and other plugins from the Rhino environment.

As a key point the real size model of a movable canopy presented at the Glasstec 2014 in Düsseldorf, Germany, as shown in figure 01 below, was an excellent demonstrator for the potential that lies in the utilization of thin glass in moveable structures. This canopy was also the initial point for the application for the research project mentioned above. Several prototype models were first studied in computer models to evaluate their feasibility and subsequently built as cardboard-models or transparent synthetic models to gradually optimize the system to finally build the real-life application.

Adaptive Components

The Adaptivity (lat. adaptare: adapt, adjust) is the reaction to environmental boundary conditions and may be applied to the field of thin glass applications. Both, reactions and boundary conditions are diverse. Facades commonly have to meet requirements concerning structural safety, air tightness, visibility, lighting, temperature and precipitation. Reactions may be changes in transparency, light guiding, ventilation and others.

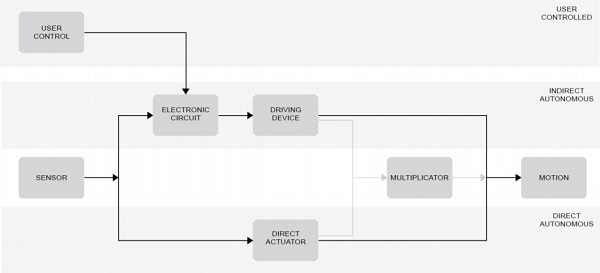

In the following, movement of thin glass edges and thin glass elements are considered as application for thin glass façades provided in this paper. The autonomous ones could be either directly driven from an autonomous actuator by transforming the physical shape change of the actuator to a movement or indirectly driven by an electronic circuit that translates a measured sensor input to an individual drive device or to a number of synchronized devices.

Changes in the geometry require for a motionsequence derived from measured information. In the case of autonomously moved elements, a direct actuation by physical effects may be scaled up to the actual movement my simple mechanical multiplier units such as scissor or lever elements.

Electric energy as well as physical impulses such as temperature, air humidity, light or pressure can be used as triggers for the flow of information. Concerning adaptivity, a promising type concerning robustness and sustainability are direct autonomous systems, which function independently of energy supply. In figure 02 individual components of adaptive systems are shown.

As mentioned in figure 02 above, the components are combined to build adaptive systems. The components that are required for adaptivity are specified in the following subchapters.

Sensor technology

Environmental surroundings such as temperature, air humidity, solar radiation can be quantified with sensors such as thermometers, hygrometers or pyranometers, and these surroundings can be converted into electrical impulses. Those impulses conduce the system controlling to generate the operating signals for actuator movements.

Actuators

The incoming signals from sensors initiate movement by actuators. The function of the latter is to power a system or mechanism. Actuators can be separated into two groups, autonomous and controlled actuators.

Autonomous actuators

Intelligent materials take on the task of the sensors to control themselves without the use of control technology. Adaptive functional materials can be divided into two groups: semi- smart materials are able to adopt changes on a few occasions. Smart materials have permanent reversible characteristics, which can be triggered by physical influences such as temperature, light, pressure, electrical impulses, magnetic impulses or chemical impulses. [1]

The greatest advantage of autonomous powering systems is a permanent workflow and no dependence on, for example, energy. Various forms of autonomous actuators are shown in the following chapter entitled “Adaptive Systems”.

Controlled actuators

The transferred command from sensor technology is part of the process cycle and initiates the actuator, as shown in figure 3. With controlled systems, process engineering is relevant, for example, electric energy is converted as a signal through electrical linear actuators into a linear motion.

![Figure 3 Electric linear actuator [2]](/sites/default/files/inline-images/Fig3_24.jpg)

Multiplicators

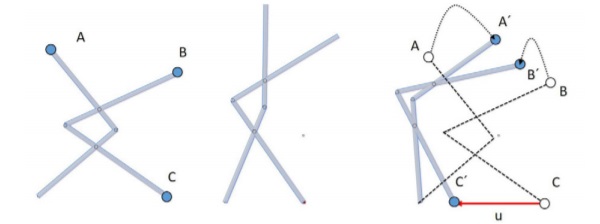

Multiplicators are used to increase the efficiency of a system. Mechanical motion driven by the actuator is a product of force and path. As an example, a small displacement u of point C to C´ is transformed to scaled movement of points A to A´ and B to B´, as in the lever system shown in figure 4. Depending on the geometry the transformation may be set as desired.

Generally multiplying units can be built as gears, belt drives and others and can also be used as a force multiplying process which can be carried out in a rotary or linear fashion. [3]

Adaptive Systems

The most impressive way to work with adaptive systems is by using autonomous elements. Self-regulation of those systems is the result of the correct combination of various components and the purpose is to create autonomous façade applications.

Two strategies of adapting façades are described in the following sub-categories: the transparency of façades as well as the way façade applications can be moved, both of which can be carried out autonomously

View

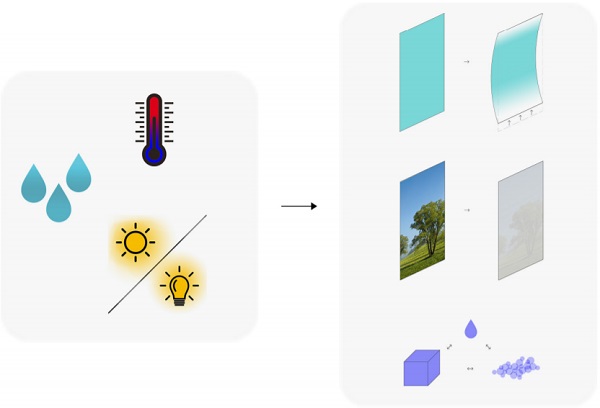

Primarily, the function of façades is to separate the interior and exterior. Furthermore, aesthetics and design are of architectural importance and structural-physical values are responsible for comfort. Even if the level of transparency in façades is relevant for the light intensity in the room, they cannot protect from overheating due to solarisation. Therefore, creating autonomous regulation is a factor to save energy over the entire life cycle.

Thermochromic resin layers with nanocapsule structure, located between the glass layers, can be used as a switching tool. The level of transparency is a result of the nanostructure, which enables solar radiation to pass through the resin layer. In order to achieve the switching temperature, the structure of the nanocapsules change and become diffused which, in turn, increases reflection. [4] & [5]

![Figure 6 Functional principle of thermotropic laminated glass, [4]](/sites/default/files/inline-images/Fig6_22.jpg)

![Figure 7 Thermochromic glazing in low (a) and high (b) temperature state, [6]](/sites/default/files/inline-images/Fig7_20.jpg)

Motion

Bi-wood

Various parameters, such as thickness, type of wood and content of moisture can be used to control and design the behaviour of wood. The reaction of wood to humidity is invertible, meaning that the initial state of wood is achieved after drying out. Using humidity to change wood is based on three major parameters: dimensional ratio, grain orientation and lamination. [7]

The hygroscopic properties of a cone - which is in a closed state during wet conditions and in an opened state in dry times, when the seeds can be spread by winds - can therefore be functionally reproduced by wooden bi-layer constructions composed of a resistant and of an actuation layer. [8]

![Figure 8 Shape transformations of bi-layered wood due to hygroscopic properties, through A) twisting, B) bending, C) sinusoidal curved. [9]](/sites/default/files/inline-images/Fig8_20.jpg)

Adaptive façades made from thin glass can be regulated by bi-wood constructions. The dependence of wood on humidity and its return to its original state after drying and moistening in combination with lamination of the bilayers, are an attractive option to power autonomous systems.

Bi-metal

Actuators made of bi-metal are thermally active elements which continuously deform owing to thermal variation. Bi-metal in form of stripes, ribbons or rolls are common examples of use. More specific applications are thermal snap discs and elements that work discontinuously owing to their geometry. A coating process, galvanic or chemical, further improves the corrosion resistance of the elements. [10]

![Figure 9 Bi-metal ribbon, [10]](/sites/default/files/inline-images/Fig9_14.jpg)

Bi-metal ribbons fixed to thin glass might be used as an autonomous temperature control system for façades. A rise in temperature due to solarisation, the shade or air ventilation systems work due to deformation of the façade application.

Shape memory alloy

Shape memory alloy actuators take up the original position using temperature variation. Disposable elements change their form when heated. In contrast, two-way components take on a high temperature form when heated and a low temperature shape when cooled.

![Figure 10 schematic shape memory alloy effect, [11]](/sites/default/files/inline-images/Fig10_11.jpg)

Another specific model is a shape memory alloy system which works with a disposable element and a counteracting force. It is an economic, self-sufficient solution enabled by reversible deformation, as displayed in figure 10. [10]

For thin glass applications in façades, shape memory alloys are another way of generating motion. If solarisation activates thin wires, the contraction due to the shape memory alloy enables the deformation of thin glass. [12] Especially the advantage of several positions that can be perceived are of particular interest for energy generation – PV elements.

Thin Glass Applications in façades

Infinity lights

Infinity lights is the solution, designed in the range of a master-thesis, for a skyscraper in Manhattan. Thin glass modules are used to guide natural light. With different angles, as mentioned in figure 11, the façade reacts to the sun position and allows natural light far into the interior space. The maximal angles of the reflection element are structurally specified the transport of light is connected to the atmosphere of the indoor daylighting.

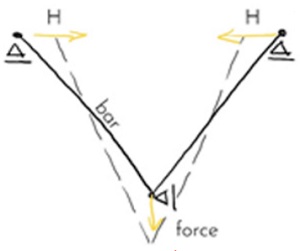

The kinematics in this structure, shown in figure 12, follow a linear motion sequence. The force generates tensile forces in the vertical non-locating bearing, which are directed by two bars in a horizontal non-locating bearing and thus trigger movement H. The dashed line shows the change in position of the system.

Self-regulating air ventilation

This model, vertical, rectangular façade elements overlap in the fashion of roof tiles. To enable air ventilation, based on a given surface temperature of the façade, bi-metal ribbons or shape memory alloy wires are fixed at both vertical edges.

The movement of the end points in z-direction is creating the gathering, as shown in figure 13. The advantages of this idea are a small path of movement and a larger opening. Furthermore, it is an autonomous form of air ventilation control and causes the thin ribbons or wires to be discreet in design solutions.

The self-regulating air ventilation system is designed as a double-skin-façade, the interspace can be cooled using the stackeffect, especially in the case of overheating in summer.

Thin film photovoltaic

A combination of energy and shade production were the goals of Sheila Kennedy’s Soft House. [13] These aspects were the initial idea for using thin glass elements as façade with vapor-deposited thin film photovoltaic technology. The advantages are powerful: adaptable orientation of the modules due to sun position and the production of energy in connection with shading, as can be seen in figure 14.

This application is mainly used for southorientated façades. The outer layer of the double-skin-façade is triggered to enable the tracing of the solar altitude.

The initial form of the thin glass element is a part of a cylinder. By defining a rotation point in the centre of the fixing rails on the top and the bottom of each element, a minimum movement is needed to change the direction of the surface, see in figure 15, therefore less energy and time is needed to adjust each element to the optimal position concerning the incidence angle of current sunlight.

The concept takes advantages of shape and material properties of thin glass to produce environmentally friendly energy but also provides flexible design options for façades as the resulting conical forms offer a various amount of different appearances.

Conclusion

The aim of this research work is to find new fields of application for thin glass in buildings. One kind of new application is the field of movable and adaptive systems. Due to the high flexibility of thin glass, new design options for example of facades become feasible in comparison to regular thicknesses of glass. Based on the known theory of developable surface new kinds of “organic” facades can be designed.

With cold bend glass or curved laminated safety glass produced by laminating glass plies, very interesting elements in the facades can be achieved. Possibilities of movement, with the meaning of a permanent bending of thin glass, for example for elements of the façade which can be opened and closed, creates new tools for the design process of architects.

The research work in future will explore new fields of application for thin glass. These new applications should be categorized according to their concept, for example, the theory of developable surfaces or curved folding. Based on the two basic types of movement - translation and rotation and their combination – new “lively” systems of thin glass structures will be developed.

Acknowledgement

This paper is the result of a project by the research centre named the “Josef Ressel Centre for Thin Glass Technology for Structural for Structural Glass Applications” funded by the Austrian “Christin Doppler Research Association” and is supported by industry partners SFL Engineering GmbH and LISEC Austria GmbH

References

[1] Schumacher, Michael; Schaeffer, Oliver; Vogt, Michael-Marcus. (2010). Move architecture in motion: dynamic components and elements in architecture. Basel: Birkhäuser.

[2] Alibaba (Hrsg.): <https://www.alibaba.com/product-detail/LMI10-Series-Electric-LinearActuatorsfor_50030493193.html>. 24.04.2019

[3] Novacki, Zoran: Wandelbare lineare Tragsysteme – Analyse und Neuentwicklung. [Diss. TU München, Fakultät für Architetkur 2014] S.20 ff

[4] Rabe, Christian / Frauenhofer Institute for Applied Polymer Research IAP (Hrsg.): SolardimEco. High energy savings through a self-regulating solar protection glazing. <https://www.iap.fraunhofer.de/content/dam/iap/en/documents/FB2/Solardim_ECO_Fraunhofer-IAP.pdf>. 10.04.2019

[5] Bianco, Lorenza; Goia, Francesco; Serra, Valentina; Zinzi Michele (2015): Thermal and optical properties of a thermotropic glass pane: laboratory and in-field characterization. IBPC 2015.

[6] Seeboth, Arno; Lötzsch, Detlef: Thermochromic and Thermotropic Materials. [eBook] 2014. S.181

[7] Abdelmohsen, Sherif; Adriaenssens, Sigrid; Gabriele, Stefano; Olivieri, Luigi; El-Dabaa, Rana (2019): Hygroscapes: Innovative Shape Shifting Façades. In: Digital Wood Design. 2019.

[8] Poppinga, Simon; Zollfrank, Cordt; Prucker, Oswald; Rühe, Jürgen; Menges, Achim; Cheng, Tiffany; Speck, Thomas: Toward a New Generation of Smart Biomimetic Actuators for Architecture. In: Advances Materials; 1703653, 2017.

[9] Holstov, Artem; Farmer, Graham; Bridgens, Ben (2017): Sustainable Materialisation of Responsive Architecture. In: Sustainability, Volume 9, Issue 3. 2017.

[10] G.Rau GmbH & Co KG (Hrsg.): Produktbroschuere. <https://www.g-rau.de/fileadmin/gustavrau/downloads/service/downloads/produktbeschreibung/Produktbroschuere_web.pdf>.08.04.2019

[11] G.Rau GmbH & Co KG (Hrsg.): Thermische Aktuatoren. <https://www.g-rau.de/fileadmin/gustavrau/downloads/service/downloads/Thermische_Aktoren.pdf>. 08.04.2019

[12] Louter, Christian: Dünnglaskonzepte für architektonische Anwendungen. In: Weller, Bernhard; Tasche, Silke (Hrsg.): Glasbau 2019. Wilhelm Ernst & Sohn Verlag. 2019, S.242-243

[13] Stauffer, Nancy W., MIT Energy Initiative (04.06.2013): Building facades that move, textiles that illuminate. <http://energy.mit.edu/news/buildingfaçades-that-move-textiles-that-illuminate/>. 12.04.2019