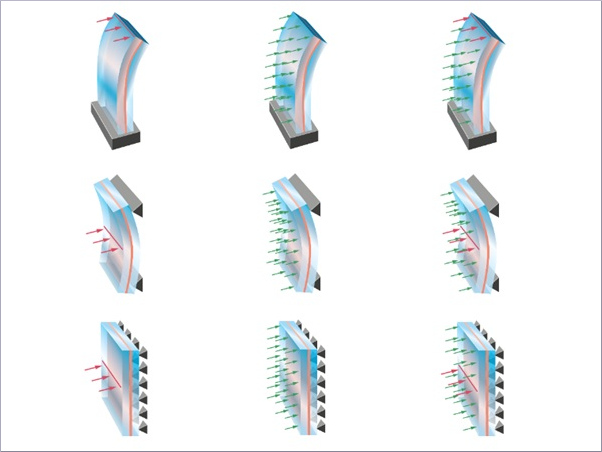

1. Introduction – Nowadays glass is one of the most used materials in technological construction due to its transparency and its sense of spaciousness. One of the main problems of glass façades is concerned with solar radiation and thermal isolation. To increase the thermal isolation of a double glass pane, air chambers with Argon and low emissivity layers are accomplished. To avoid the entrance of solar radiation through glass panes, reflective layers or blocking layers of infrared radiation have been developed.

However, glass façades has not thermal inertia and solar radiation cause greenhouse effect inside the buildings. As a result the interior is overheated and comfort decreases. In order to avoid these negatives effects, Intelliglass has developed a revolutionary glazing system: a double glass pane with a circulating water chamber that transports the absorbed solar energy.

Since water is transparent to visible radiation and opaque to infrared radiation, only the desired visible part of the solar spectrum enters into the building. The result of the combination of glass and water is an active glazing system which is able to transport the absorbed energy along the façade to an energy storage water tank. Later, this energy can be used for air conditioning purposes or to produce domestic hot water. If there are no needs of heat and the thermal storage water tank reaches its thermal set point, energy surplus is dissipated by exterior low temperatures or by evaporative cooling.

The main goal of the system is to create an isothermal envelope of the building to reduce the HVAC energy costs without giving away the advantages of the use of glass. To do so, the Intelliglass system offers integration of the product in the façade or roof to eliminate the solar thermal load before it gets inside the building. The shielding of the sun radiation prevents greenhouse effect making immediate energy savings. Furthermore, it contributes to an improved thermal comfort inside the building eliminating thermal gradients.

Double glazing pane with circulating hot or cold water can also be used to build partitions of buildings. Hence, thermal loads can be compensated with these inner partitions called RadiaGlass. On the other hand, thermal inertia is increased when using RadiaGlass partitioning system and iThermGlass glass façades. By this way, inside temperature oscillations are controlled by this extra inertia reducing the peak demand and the energy consumption of the building.

The double glazing with water has been also used to develop a new type of solar collector, called HeatGlass, which can be easily and aesthetically integrated into the building’s façade or roof. The solar energy is absorbed and later it can be used to heat the interior of the building or to provide domestic hot water if needed.

The objective of this paper is to demonstrate by means of numerical simulation the viability of a zero thermal energy building with IntelliGlass technology. This paper describes the building and the energy management system. The results of the building simulation are also presented and discussed.

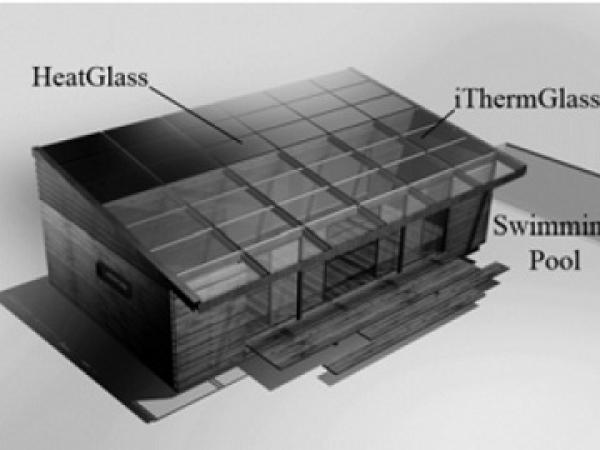

2. Building and energy management system description – The building of this study is a 70 square meter prototype dwelling covering the basic living functions: kitchen with dining, bathroom, living room and two bedrooms. Living room is an open space with iThermGlass roof and glass sliding façade facing southeast. Bedrooms have small windows facing north. Foundations of the building are done using the energy storage water tank of reinforced concrete. This tank is isolated with 30 cm thick EPS panels.

The structure of this dwelling is formed by steel columns (square steel tube) which are connected with high strength bolts at the concrete tank. Laminated timber beams will be bolted to the steel vertical structure to form the roof. The external wall consists of 50mm thick wooden boards for the exterior side, light wooden boards for the interior side; the cavity between wooden boards is filled with 100 mm thick EPS panels.

Roof is solved with IntelliGlass technology: transparent iThermGlass panels in living room to provide natural light, and an opaque HeatGlass panel over the bedrooms to absorb solar energy for Domestic Hot Water or energy storage in the water tank. Interior Partitions are RadiaGlass panels which are used to compensate internal thermal loads.

.jpg)

Figure 1. Image of the low energy dwelling.

The main goals of this construction system are: (i) the integration of active glazing panels in the envelope of the building, (ii) The energy management system as a part of the whole building, (iii) industrial construction because steel structure and other building materials are well designed and manufactured in workshop, (iv) excellent performance in heat and sound insulation by using wood and EPS layers applied on external wall, internal wall, flooring and roof.

.jpg)

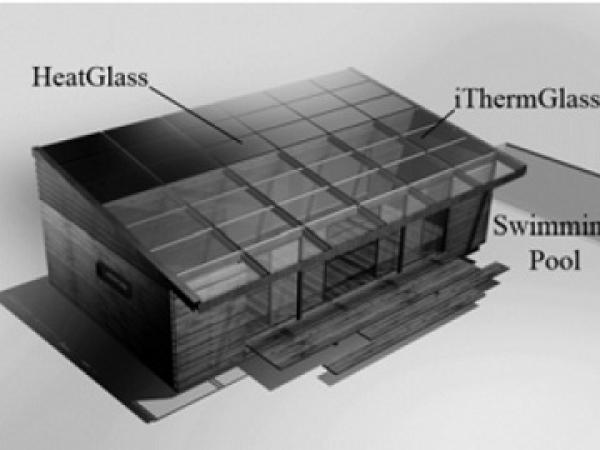

Figure 2. Principle scheme of the energy management system.

Energy management system of this building is based on a primary ring in which the different devices (iThermGlass, HeatGlass, RadiaGlass, DHW, storage water tank and swimming pool) are connected. Each one acts as an energy producer, energy storage or energy sink. The primary ring and the devices have a circulating pump which can be turned on or off independently. Each device is connected to the primary ring by a plate heat exchanger that allows giving or taking energy from it.

Hence, energy can be transferred from one device to another through the primary ring. For example, turning on the circulating pumps of HeatGlass, RadiaGlass and the primary ring and turning off the other ones. By this way, the solar radiation captured by the HeatGlass is used to heat the RadiaGlass inner partitions.

The circulating pumps are operated by an electronic control system that will be explained later.

Since the water flow direction in the primary ring is fixed, the order of the devices is important. For this project the order is: iThermGlass, HeatGlass, RadiaGlass, DHW, Storage Water Tank and Swimming Pool.

The operation of the energy management system works as follows. In winter solar radiation enter through the south façade. To avoid thermal oscillations, thermal inertia is controlled by RadiaGlass. Besides, iThermGlass and HeatGlass absorbed solar radiation which is transferred by means of the primary ring to other devices. This energy can be transferred directly by means of RadiaGlass panels to heat building interior or can be stored in the storage water tank.

The use of Radiaglass partitions can eliminate the internal thermal loads without temperature gradients or air flows. Finally, RadiaGlass increases the thermal inertia of the building interior reducing the internal temperature variation during the day and therefore reducing the peak demand of energy. When external conditions do require, circulation of water can be stopped so iThermGlass panels will capture a higher solar radiation and therefore to increase the water temperature to approach it as maximum to the comfort temperature.

In summer, iThermGlass roof has a glass eave to protect the south façade from infrared radiation. Hence, solar radiation is blocked by the iThermGlass and HeatGlass roof. This heat is transferred to the management ring which decides which energy must be transferred to the storage tank or to the swimming pool. During the night the swimming pool allows evacuating the heat excess captured in the roof. The system made in this way can perform the best strategy taking into account the day and the building occupation.

3. Control system - One of the most important characteristics of the energy management system is its control system. As seen in the precedent section, the building has several different devices that must operate co-ordinately to get the best results in terms of comfort and energy efficiency. In this section the logic behind the control system will be described. The control system operates turning on or off the water pumps of the different devices and of the primary ring to transport and manage the energy of the building.

The two objectives of the control system are: to provide a comfortable inside environment and to reach great energy efficiency. To achieve these two objectives simultaneously, it is needed to assign priorities. The main priority is to maintain the inside conditions into the thermal comfort range. Once the set point of the comfort temperature is reached, exceeding energy is used to heat the storage water tank or the swimming pool.

Another important characteristic of the control system are the two different modes. Depending on the season of the year, the system operates in the “Summer” or “Winter” mode. These two different modes are necessary to adapt the system behaviour to the environmental conditions.

The summer mode acts between May and September. To cool the interior of the building, natural convection is used. The control system tries to cool the thermal inertia of the building during the night. This strategy called “night cooling” improves greatly the energy efficiency of the building reducing or eliminating the need of cooling energy during the day. The solar energy collected by the HeatGlass is used to heat the pool trying to keep it at 35ºC.

The winter mode acts the rest of the year and his logic is slightly more complicated. When the building’s inside conditions are such that heating the interior is needed, the control system verifies if the HeatGlass or the water tank can provide it. The availability of the HeatGlass is verified with a thermostat that compares the solar collector temperature with the inside temperature. If the difference is higher than 7ºC, it is assumed that the HeatGlass can heat the interior. A similar comparison is made to verify the water tank availability.

If any of them are available, the system turns on the RadiaGlass interior partition that it’s heated with the energy coming from the HeatGlass or from the water tank, which water pumps are also turned on (giving the priority to the HeatGlass). If the interior of the building does not need to be heated and the iThermGlass or the HeatGlass are collecting solar energy, this energy is stored in the water tank to be used when needed. If cooling is requested, the control system uses natural ventilation as it does in the summer. In this case no “night cooling” is needed.

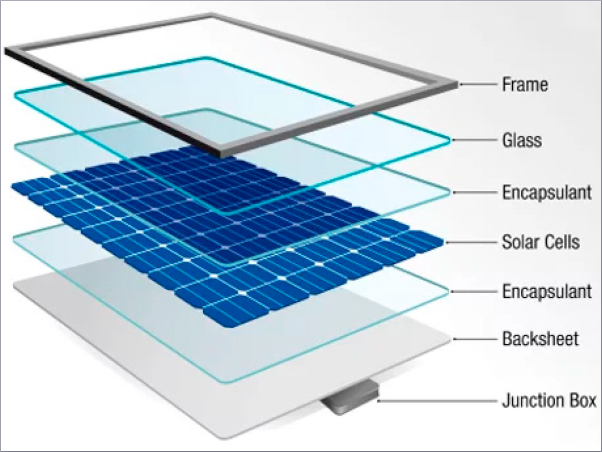

4. Numerical Results and Discussion – To analyze the building’s thermal behaviour with the active glazing, proprietary building physics software has been developed. This software is able to simulate the thermal and spectral response of an active glazing [2].

To validate this software a yearly simulation for a sample test case is ran. Our results were compared with the results obtained with well known validated building physics software EnergyPlus for the same test case.

.jpg)

Figure 3. Comparative of simulation results with two different programs.

The inside temperatures are obtained with both programs for a period of four weeks. The results are shown in the figure 3. Results show a good agreement between our simulations and EnergyPlus simulations. Considering that the physical and mathematical models have a few differences in meteorological data used, it can be concluded that the proprietary software is able to provide enough accurate results to our purposes.

After validating the software, a model of the studied building and the logic control system is implemented to run a simulation.

In the figure 4, outside, inside, water tank and swimming pool daily average temperatures are plotted. To show the difference between active or passive strategies the same without water flow is simulated in figure 5.

.jpg)

Figure 4. Simulation results for the building with the IntelliGlass system.

.jpg)

Figure 5. Simulation results for the building without the IntelliGlass system.

Observing the figure 4, can be appreciated that the inside temperature of the building equipped with the IntelliGlass energy management system is between 20ºC and 26ºC for almost all the year. This temperature range can be considered as the thermal comfort range, so thermal comfort is achieved without any additional air conditioning system and with low energy consumption.

Comparing this results with the results for the building without this system, it can be seen that the inside temperature is outside the thermal comfort range for long periods of time. For this building an airconditioning and heating system is needed, increasing greatly the energy consumption of the building.

Another advantage of the IntelliGlass system is that the swimming pool period use is increased. The swimming pool heating also protects the solar collectors from overheating in summer.

5. Conclusions – New simulation software has been developed and validated by means of EnergyPlus simulations. This simulator allows studying the thermal behaviour of a building equipped with the IntelliGlass technology with a logic control system.

The primary energy ring allows a great number of strategies to transfer energy from one device to another. The design of the control logic is very relevant in order to obtain great energy efficiency. Numerical results are shown to demonstrate that a bad strategy can perform poorly in terms of energy consumption and thermal comfort. For the building studied here, the results of the simulations show that is possible to obtain zero energy consumption in HVAC even in such an extreme climate.

As a final conclusion can be said that the use of the iThermGlass active glazing technology in the façades, combined with the active RadiaGlass inner partitions and the HeatGlass solar thermal collectors allows to maintain the thermal comfort inside the building at a much reduced energy consumption, obtaining a thermal zero energy building.

6. References

[1] U.S. Energy Information Administration,“International Energy Outlook 2010”, http://www.eia.doe.gov/oiaf/ieo/index.html, 2010.

[2] W. Kays, “Convective heat and mass transfer”, McGraw-Hill Education, 2004.

[3] A. Bejan, “Convection heat transfer”. Wiley, Hoboken N.J., 2004.

[4] R. Siegel, “Thermal radiation heat transfer”, Taylor & Francis, 2002.

[5] A. Alonso González, “Ahorro energético en edificios climatizados mediante sistema IntelliGlass ”, Univerisdad Politécnica de Madrid, 2010.

[6] I. Pontijas Fuentes, “Estudio del comportamiento espectral y térmico de acristalamientos activos RadiaGlass”, Universidad Politécnica de Madrid, 2009.