Date: 16 September 2005

This allows you to work with small or very large glass pieces.

In addition to the above, the drill can work alone or be incorporated into a line along with a double edging machine.

The line and individual machinery give the highest yield and speed for the pre-processing of glass before tempering. The glass handling is reduced when you work online, giving you the best working environment for handling sensitive soft coated glass such as Low-E. The benefit when you minimize the glass handling: is that your production costs will be reduced as well.

The double edger and drill are also available for jumbo size glass sheets up to 3300 mm width and 7200 mm length.

Selective storage for REV SLH cutting system a compact line with storage built right in

The compact cutting line, REV SLH cutting system has grown to become an entire cutting and storage solution for the busy glass working company. This unique cutting line now incorporates a 4 element frame storage station for up to 4 different types of glass. Thus this REV model cutting system offers the perfect solution for precision, productivity and space-saving in your factory design.

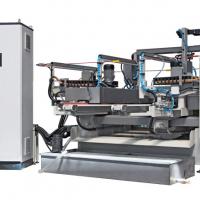

The new ALPA N series with an optional loading system a cost effective alternative for loading a CNC machine

The CNC Working Center ALPA 315 is now available with an optional loading/unloading system. This new design loader/unloader allows a very safe and functional method to load the Alpa N Series CNC more efficiently and cost effective. It is an interesting alternative to the CNC working machine loaded by R6 robot.

Add new comment