Date: 6 May 2025

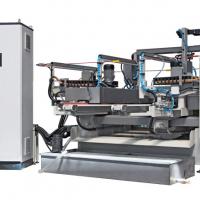

The orders are booked in Glaston’s Q1 2025 order book. They include an ULTRA TPS® line for manufacturing insulating glass units with ultra-thin center glass, MULTI’ARRISSER machines for edge processing, and an FC Series X machine for glass tempering. The orders will be delivered in the second half of 2025.

Regency Glass has a long experience in providing insulated glass units for the replacement and new build market in the UK. Relying on Glaston’s technology, the company is now expanding its production capabilities, specifically designed to produce ultra-thin triple-glazed insulating glass units.

The triple IG unit with ultra-thin center glass down to 0.5 mm is significantly lighter than conventional triple IG units, and it offers high-performance glazing in a slimmer, more efficient package. These units offer up to 35% better U-values than conventional double glazing, while also addressing the issues of thickness and weight. Regency Glass’s new triple glazed offering is only 5% heavier than a conventional double IG unit.

Regency Glass has a quality and efficiency-driven operating model. Glaston was the only vendor capable of providing the needed technology to meet their production quality and efficiency requirements. The customer has already automated its glass tempering process with Glaston’s Autopilot and will continue utilizing those capabilities in the future, too.

“Building on top of the automation capabilities, Regency Glass had the opportunity to plan their new offering around the production process of new ultra-thin IGUs. The production design makes the most of the proven TPS® technology and a patented processing method created specifically for ultra-thin glass,” says Sasu Koivumäki, Chief Sales Officer at Glaston.

“We focus on investments that will meet the future requirements of the glazing industry. To address the market's growing need for energy efficiency, we see a potential for ultra-thin insulating glass units with a better U-value that fit the existing window frame width. With Glaston’s technology and process know-how support, we are confident we will maintain our established production quality and reliability when stepping into a new production field,” says Wayne Fitzmartin, Chief Operating Officer, Regency Glass.

600450

600450

Add new comment