Date: 7 May 2025

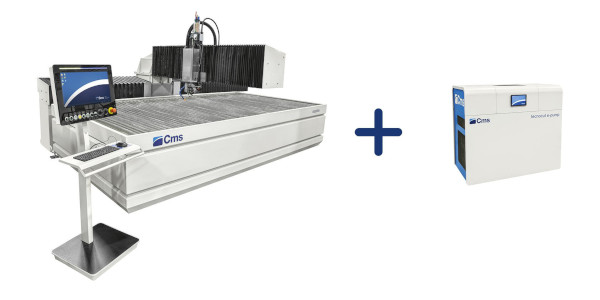

Now, thanks to the integration of the hybrid pressure intensifier, the system guarantees even higher performance, reducing consumption and maintenance.

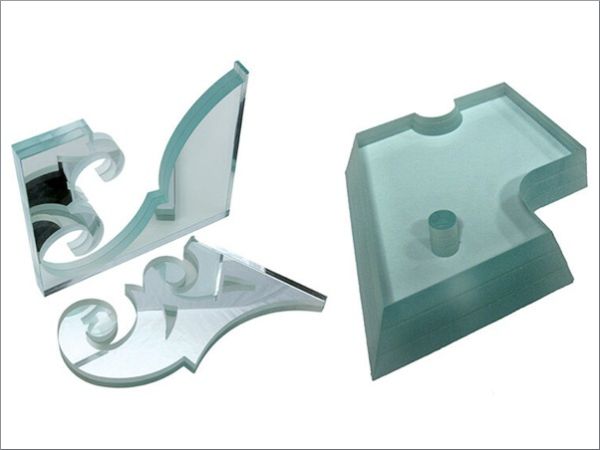

The easyline waterjet cutting system is CMS Glass Technology's agile and versatile solution for glass cutting. With a cantilever structure with independent tank and advanced solutions such as the pendulum cycle and the multi-head configuration, easyline makes the production process even faster and more efficient.

Easyline is supported by the new hybrid pressure intensifier e-pump, which combines the power density of hydraulic pumps with the energy efficiency of a direct drive mechanical architecture.

E-pump offers 31% higher operating efficiency compared to traditional intensifiers, which translates into less maintenance, higher productivity and a reduced environmental impact.

Why choose the easyline + epump combination?

- Efficiency and energy saving: e-pump guarantees 31% higher efficiency compared to traditional intensifiers, reducing energy consumption by up to 37%.

- Minimum maintenance: e-pump's hybrid technology uses 95% fewer hydraulic components, reducing costs and machine downtime.

- Advanced sustainability: 91% reduction in hydraulic oil use and a lower environmental impact.

- Production flexibility: possibility of processing a wide range of materials, with tailor-made solutions such as the pendulum cycle and the multi-head configuration, to increase productivity by up to 55%.

Trust the experience of CMS Glass Technology and contact us now!

600450

600450

I appreciate that CMS isn’t just hyping performance—they’re addressing sustainability and workflow flexibility. The 91% drop in hydraulic oil usage isn’t just eco-friendly—it means fewer fluid-related failures and spills, which is great for safety and compliance. The pendulum cycle and multi-head options show they’re thinking about actual production needs, not just lab metrics. used cars for sale newfoundland