Date: 29 November 2019

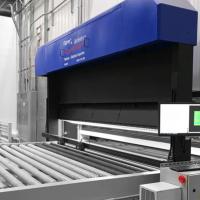

WEHA-THERM uses a LineScanner on a Lisec-KSR for glass quality testing, a second LineScanner on a Lisec insulating glass system for testing single glass. With the help of the LineScanner the complaint rate at WEHA-THERM could be reduced considerably.

"Our employees are also satisfied with the results," says Mr. Freund, Managing Director of WEHA-THERM, explaining why: "In the past, almost no one wanted to take responsibility for the assembly of large window glasses because the risk of error was simply too high. Since the LineScanners have been in use at our company, the employees are clearly more comfortable on the lines - and even when assembling large glasses, the fear has disappeared."

WEHA-THERM is also pleased with the simple handling of the LineScanners and the partnership with SOFTSOLUTION. "Thanks to the clear operation of the LineScanners and the intuitive sensitivity settings, such as the adjustment of error sizes- and contrasts using slide controls, the commissioning and training could be carried out very quickly," says Freund.

"By using the scanners, potential error sources are detected early. The control is much more stable and reliable as opposed to manual checking. We help companies to deliver consistent glass quality to their customers and thus reduce the complaint rates. Both the hardware and the software are developed and manufactured 100 percent at our site in Waidhofen / Ybbs in Lower Austria, "says Markus Stefan, Sales Manager at SOFTSOLUTION.

600450

600450

Add new comment