Date: 17 February 2020

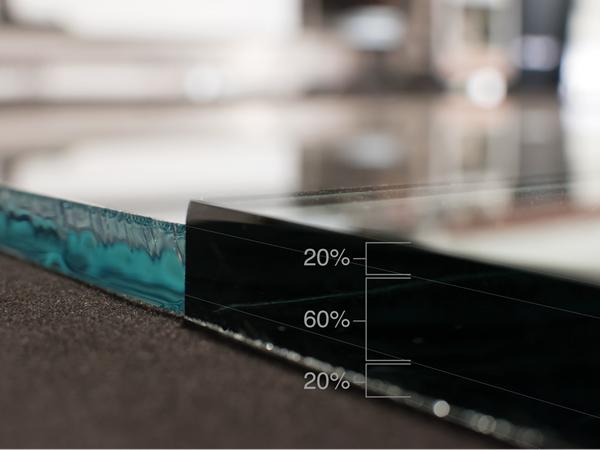

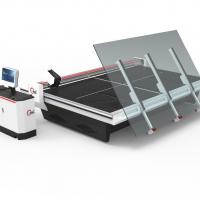

The impeccable cut is obtained when an angle of 90 degrees between the surface and the glass profile is achieved, but for many years it has been impossible to obtain this angle with the available options in the market.

The differences are accentuated when a narrow band along the edge of the sheet needs to be cut. It is here where a conventional cut will make the cutting angle not to be perpendicular. The possible edging process later will require an additional grindstone consumption to rectify the glass edge.

Additionally, in thick glass, an extra margin of several millimetres will be required to polish after obtaining the desired measure. E.g. in a 15 or 19 millimetres glass, a margin of 3 or 4 millimetres would be needed.

“The cost to polish that amount of glass is very high, therefore, this is a costly and inefficient solution in terms of production," says Miguel Angel Guillen, Director of R+D cut in TUROMAS. The thirty-five years’ experience in cutting flat glass has taught TUROMAS that, in order to obtain excellence, it is necessary to optimise the four most important parameters involved in the cut: lubrication, the angle and the diameter of the cutting head, speed, and the pressure exerted on the sheet.

Adjusting these parameters individually is not difficult, the true complexity lies in correctly applying them all at the same time. Before, the angle and the optimal diameter of the cutting head was only obtained by modifying them manually for each glass thickness.

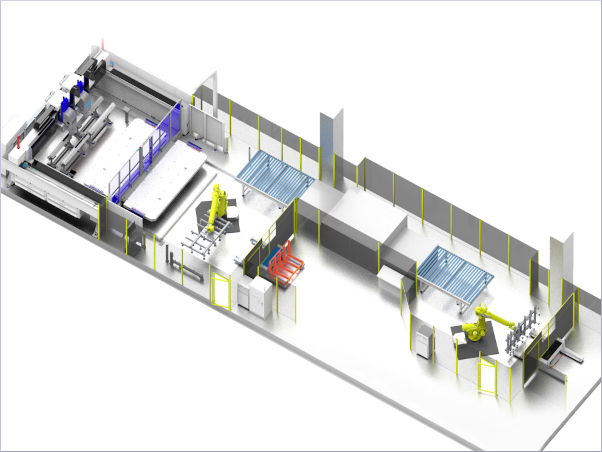

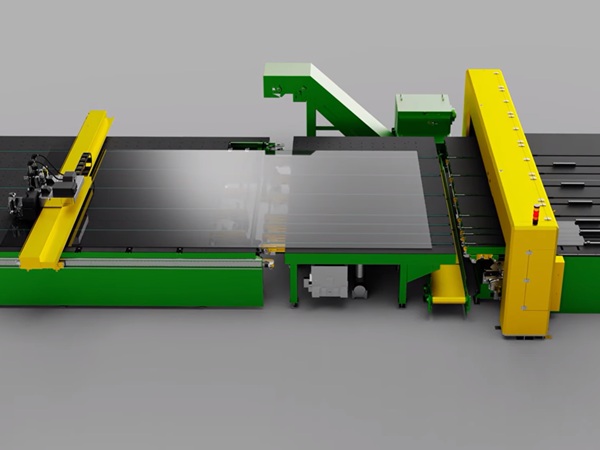

In 2008, this process changed decisively when TUROMAS developed and patented 4tool, a new pioneering technology at global level that gives you a perfect cut in any glass, whatever its thickness.

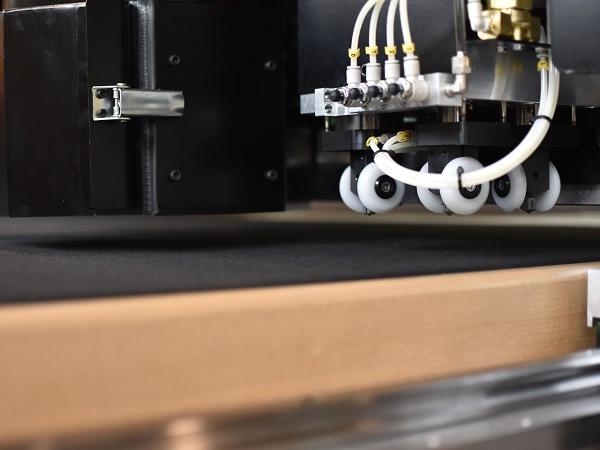

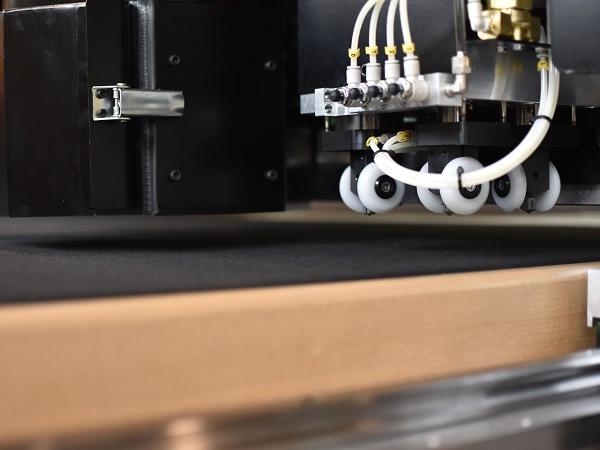

This revolutionary technology removes the manual changes of the cutting head definitely because it automatically detects the thickness and adapts the specific tool for each sheet. Additionally, 4tool integrates four individual cutting tools of automatic selection, each with its own cutting head, lubrication system and pressure cylinder dimensioned specifically for its cutting range.

The first tool is intended to cut glass from 0.55 millimetres to 2 millimetres thick. The second and third are used for glass from 2 millimetres to 12 millimetres, which are the most common thickness. The fourth tool uses a larger diameter cutting head to cut glass of 12 millimetres, 15 millimetres, 19 millimetres and 25 millimetres.

"The great consistency that you get with this system differs a lot from the fragility of the changing tool systems, where small and delicate mechanisms tend to break down with ease. In addition, the redundancy in the cutting tools keeps the machine functional, even if there is a problem in one of the tools of the head," says Miguel Angel.

This leading solution makes TUROMAS to be the sole manufacturer of machinery for flat glass able to obtain a great quality cut in any thickness, considerably reducing the subsequent glass processing, saving in costs and production time.

600450

600450

Add new comment