Date: 25 June 2025

Decorative Glass reinterprets an ancient artistic-cultural heritage with modern materials to create individually designed products. Arab Union Glass is a leading player in the flat glass processing industry, producing top-notch IG units. Together they supply architects with complete solutions to realize the most ambitious projects. In LiSEC machines & software solutions, the group of companies has a trustworthy partner supporting them to realize their vision.

The Egyptian market leader with export ambition

Arab Union Glass, a prominent Egyptian flat glass processor, was established by Mr. Sobhy El Genedy in 1960. The company takes pride in being Proudly Made in Egypt and holds certifications for ISO 9001 (quality management systems), ISO 45001, and ISO 1400112. Their commitment to quality and service ensures that they remain at the forefront of glass innovation and customer satisfaction.

Decorative Glass’s success story began in 1963, driven by a passion for glass artistry. From design to production, supply, and application, Decorative Glass offers a diverse range of solutions tailored to their customers’ requirements. The brand made significant strides in the fabricated glass field, combining quality craftsmanship with the latest exterior and interior design trends.

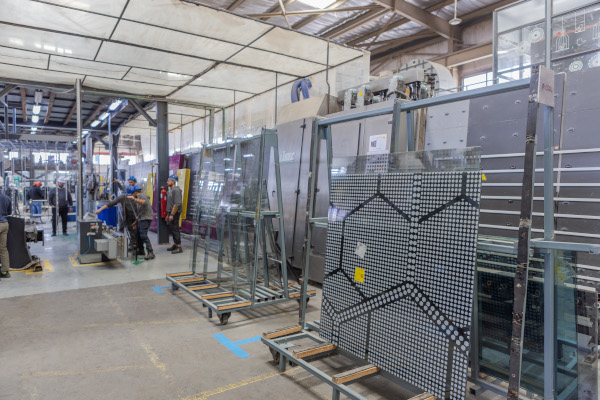

The merger between Decorative Glass and Arab Union Glass represents a milestone in Egypt’s glass history, uniting decades of experience and innovation to create something greater than the sum of its parts. It was preceded by years of cooperation and helped to solve supply chain issues as well as allowing centralized planning. Together the group of companies employs over 1,500 skilled workers who process glass in three shifts. Their collaborative effort has positioned them as market leader in Egypt.

With a combined production area of 97,000 sqm spread over multiple sites, they can offer their customers comprehensive solutions. Their product range includes laminated, pained, printed and PVD polished glass for architectural and interior applications as well as double IG units, with one factory specializing in clear glass and architectural glass while another is dedicated to decorative glass. With a current export rate of 2 – 3 %, their focus is on developing markets abroad, with partners in Europe, Turkey, Morocco, Libya, UAE, Russia and China.

Arab Union Glass, Decorative Glass & LiSEC: A longstanding relationship based on trust

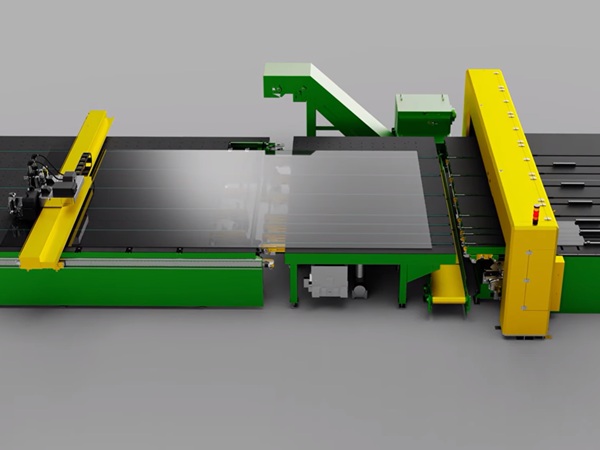

The cooperation with their local LiSEC representative, Mr. Hany Mohsen, is a success story in itself. “We’ve known each other for more than twenty years,” tells Mr. Mahmoud El Genedy, CEO of Arab Union Glass. “And we have deep trust in Mr. Mohsen. In 2003, we bought our first cutting line from LiSEC, and we remained in contact ever since.” LiSEC machines can also be found in Arab Union Glass’ IG line, where they use the KBU edge processing solution, while Decorative Glass put a LiSEC cutting table in operation in 2010.

Before every new investment, the company investigates new technologies, focussing on output and functionality. “At the glasstec, we always visit the LiSEC booth to check out the latest developments. We consider LiSEC as highly innovative, with solutions for all areas of flat glass processing,” so Mr. El Genedy.

"Our LiSEC machines work well and are highly reliable, with few downtimes. And if something unexpected happens, spare parts are quickly available."

Defending their market leadership position with high-quality glass products requires the right machinery – and well-trained operators. Mr. El Genedy says, “For the best quality products, you need the best quality team. The machines work great, it’s important to train the operators to manage them well. The training must be done on your own machines.”

Networking Arab Union Glass & Decorative Glass: LiSEC Software

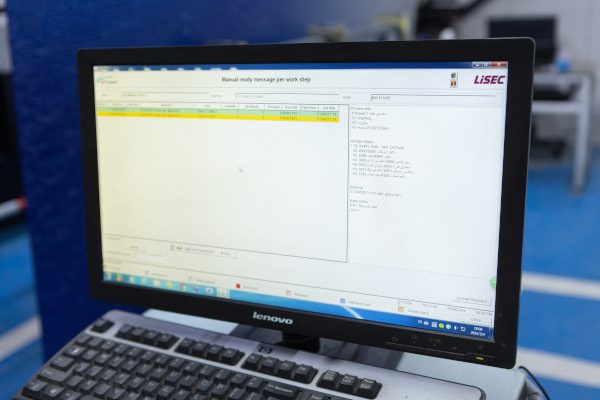

To realize high-quality products, the group of companies not only relies on LiSEC machines, but also on the appropriate software: GPS.order for order management and processing and GPS.prod for successful production planning. Mr. Tarek Bahr, Chairman of Decorative Glass, sums up his impression: “Reliable and user friendly, the software features are very useful.”

The positive results: The entire group of companies has been successfully networked. The recording and management of prices and the creation of quotations is a paperless process. All relevant information is collected at order entry and reused throughout the life cycle of the order; no further data entry required. Capacity and feasibility checks are fully automated and delivery dates are determined realistically and feasibly.

On the production side, the capacity planning module supports the fully automatic creation of work steps and work step to machine assignments based on priority rules and working time formulas. Those formulas are easy to maintain and can be edited and aligned by key users. Based on the assigned work steps and the calculated production time detailed production scheduling is possible. This allows the visualization of production gaps prior to production and gives the planner the necessary data to refine the production planning on demand.

The full integration of all these features into one production control system has significant advantages: the integration of new users or organizations, such as the group’s new factory, is easily accomplished with a multisite system with a central master data structure.

The Egyptian Market – Quality and Automation

“Especially in facades and construction, the glass market has become very attractive, drawing a lot of competitors. We have seen the number of glass processors almost triple in recent years,” recaps Mr. Tarek. “The trend is moving towards better quality end products, with requires well-performing machines. Formerly, only large glass processors imported machines from Europe – nowadays, everyone wants a good machine.”

Another major factor are the operators, says Mr. El Genedy: “It is difficult to find specialist workers, and personnel costs are rising. Automation is becoming more and more important – it saves time, money and materials, and it reduces injuries and other problems in the production.” But personnel will never be obsolete: “A major success factor in automation is having the best maintenance team. We will build up our team along with increasing the automation.”

Regarding the transformation towards full automation with all it’s effort and cost, the group follows a step-by-step approach: “We negotiate every project very well. Our next target is the completion of our new factory – the production halls are already built.”

600450

600450

Add new comment