Date: 10 October 2019

When WeWorks – the global co-working operator which provides unique office and temporary workspaces – decided to transform No.2 Dublin Landings into a cuttingedge destination for business, safety and aesthetics were high on their list of priorities.

As a traditionally industrial building in Dublin’s famous docklands, the prestigious development would need to combine its original character with the demands of modern design and legislative safety requirements to meet the needs of today’s businesses – where inspiring and flexible spaces are in high demand.

With fire safety being critical in modern construction projects, WeWorks developed and implemented a new fire safety strategy before renovating the existing building. As part of this strategy, the decision was taken to replace a fully-glazed non-fire-rated internal atrium with a new, high-performance fire-rated solution to ensure the highest levels of fire protection.

A stunning centrepiece

Spanning five storeys, the atrium would create a functional yet architecturally stunning light-filled centrepiece within the modern office space.

Forming part of the broader regeneration of Dublin Landings, bringing this aspect of the project in on time would be critical. As a result, Walls to Workstations (W2W) - who were tasked with removing and replacing the five-floor atrium – had just six weeks to see the project through to completion. Involving complete removal of the non-firerated glass and frame and installation of a new E30-rated system, W2W would rely on its delivery partners to bring the project in on time and to the highest standards of quality.

The solution

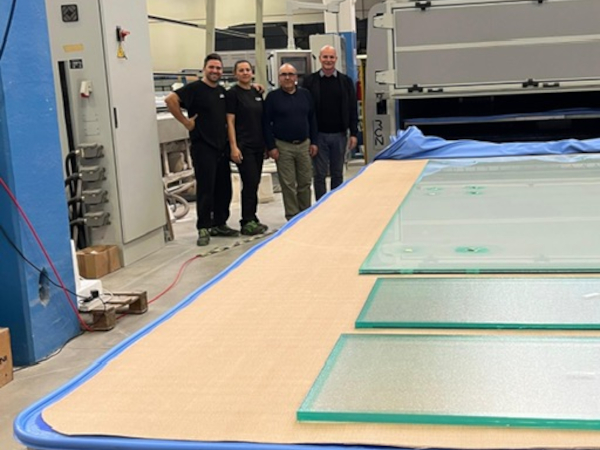

Working closely with W2W, Pyroguard supplied more than 500m2 of toughened EI30 fire safety glass to the project. Equipping fabricators with the flexibility to deliver on ambitious architectural projects which require large expanses of glazing, Pyroguard toughened glass provides protection against flames, smoke and radiant heat and delivers impact classification of 1B1 to EN12600.

Complementing modern architectural ambitions, the inclusion of large areas of toughened glazing within projects helps to safely incorporate natural light into buildings, something which is critical in renovation projects where buildings are being transformed from their original purpose.

In practice, this sees spaces flooded with natural light, elevating levels of light transmission throughout a building and having a positive impact on occupants’ wellbeing – crucial in delivering functional and inspiring workspaces.

To meet the precise requirements which had been specified for the atrium in Dublin Landings, Pyroguard was able to modify its toughened EI30 glass to meet the required line load of 1.5kn/m2 . To fit seamlessly across each floor of the spectacular atrium, various sizes would also need to be manufactured and delivered to site within weeks.

“The demands of modern office spaces have changed considerably in recent years, with businesses supporting their employees to work in ways which suit them, improving critical factors such as performance, productivity and wellbeing. As a result, modern offices look and feel very different, even to those of just a decade ago, and Dublin Landings is a great example of this.

“When we were contracted to supply and install the five-storey atrium which would flood this traditional building with light, we knew we would need to choose our partners carefully; not just to deliver the solution on time, but to ensure it met the specific safety specifications required of it. That made Pyroguard the ideal partner for this project. Their expertise within the sector meant they had the capability to fulfil the delivery of a high-performance system to fit the bespoke requirements of the space and frame, while their technical support facilitated the successful installation of the system, enabling us to bring the project in on time for WeWorks.”

Brian Kelly, Walls to Workstations

With tight deadlines now being part and parcel of modern construction projects, Pyroguard’s production capabilities enable its fire-rated glazing solutions to be delivered quickly and to the precise specifications of individual projects. For Dublin Landings, this manufacturing capability – coupled with the co-operation and project planning of W2W – enabled Pyroguard to deliver all 500m2 of toughened 32mm EI30 atrium glass to site within just four weeks, allowing sufficient time for installation within the project deadline.

600450

600450

Add new comment