Date: 23 October 2018

The process was developed for the production of "Smart-Window" glasses. Further fields of application are the production of any kind of laminated flat glass, including glass-glass PV modules.

The Bürkle IFL process (IFL=Inline Flat Lamination) is distinguished by:

- Particularly fast lamination of laminated glass compared to autoclave processes (reduction of lamination costs)

- Fully inline lamination process

- Highest laminating quality due to particularly homogeneous heating plates, heating the lamination stack from both sides

- Particularly flexible with regard to different glass structures, short set-up times for product changes

- The possibility of lamination with particularly low pressures

- Suitable for lamination of laminated glass with different thicknesses

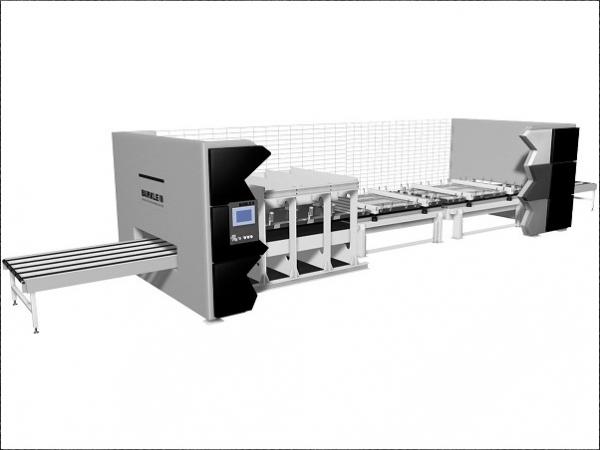

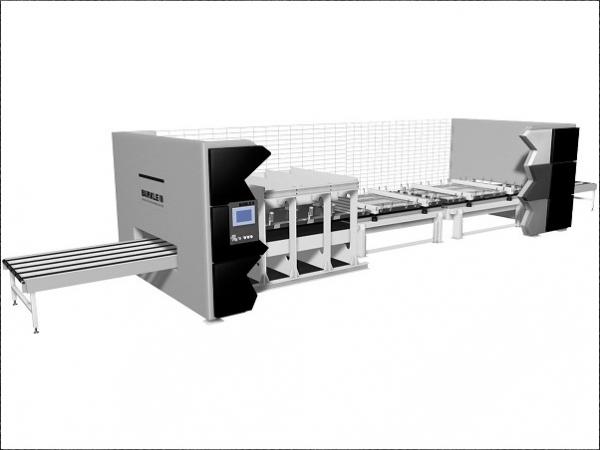

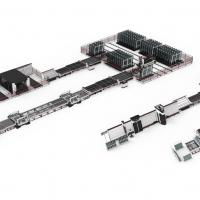

The Bürkle IFL process is a multi-stage laminating process, which uses a vacuum flat press with top and bottom heating platens in the first step. For thick glass, a second hot lamination step is recommended, using another flat press that also applies heat from above and below to the product. A flat press with water cooled press plates is then used to cool the laminated glass.

The glass is fed into the laminator in batches formed on the infeed conveyor. The laminator has an effective area of 2.200mm to 4.200mm (other effective areas on request). In the first step, the air between the layers of the glass laminate is removed by vacuum (< 1mbar). Subsequently, the layers are laminated by pressure exerted by a flat press heated on both sides. The cycle time is usually considerably less than 10 minutes.

When laminating thicker glass, the entire batch is conveyed to an optional second flat press, which also applies heat to the product from both sides and finishes the lamination. In a final step, the cooling of the laminated glass takes place in a cooling press cooled on both sides for a defined process completion and further processing.

The flat press design enables homogeneous, parallel lamination and, above all, avoids the overpressure around the edge of the glass, and thus the “edge pinching” familiar from membrane laminators. The heating of the press platens on both sides ensures faster lamination, evenly from both sides and thus considerably reduces any inherent stress between the glass layers and any deformation after lamination.

Bürkle is a technology and world market leader for press, laminating and coating technology. The headquarters of the company, founded in 1920, are located in Freudenstadt in the northern Black Forest. With approx. 500 employees, Robert Bürkle GmbH presents itself as a modern, future-oriented company that supplies highly complex high-tech press and coating systems for the furniture, plastic card, printed circuit board, glass and photovoltaic industries.

The Bürkle IFL process will be exhibited at this year's Glasstec in Düsseldorf from October 23 – 26, 2018 at the booth of Robert Bürkle GmbH, hall 12, booth no. A22.

600450

600450

Add new comment