Date: 13 November 2020

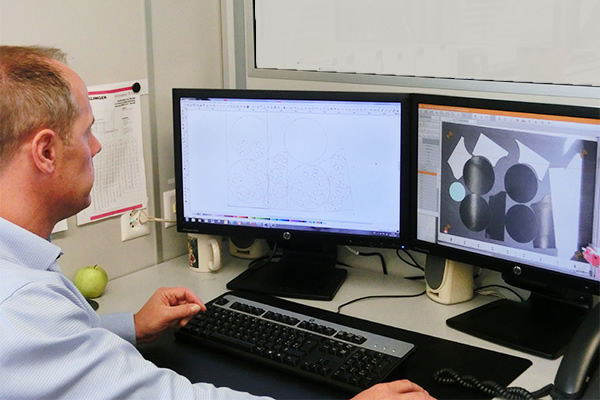

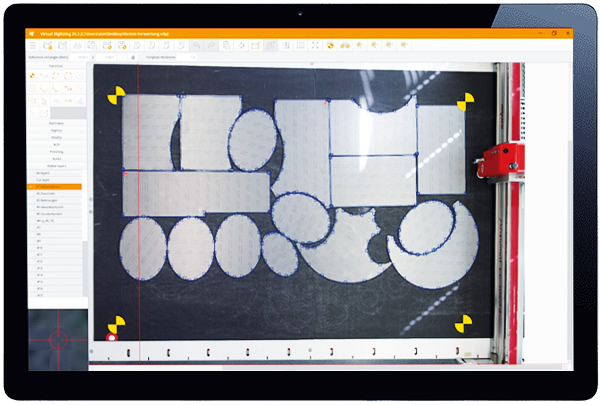

This can easily be remedied by using digitizing software such as VirtualDigitizing by SOFTSOLUTION, which allows a quick digitizing of templates, patterns and 2D objects.

// Digitizing templates in practice at FRANZ GYSI AG

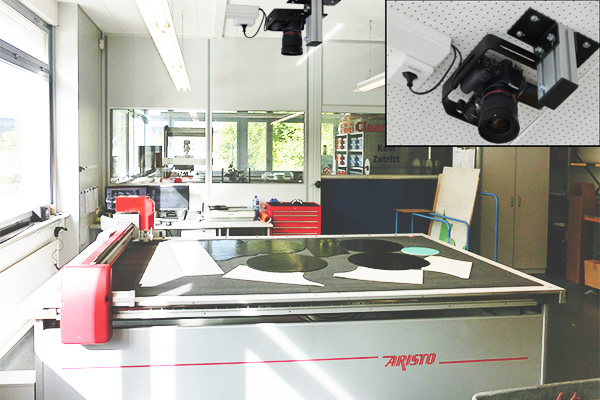

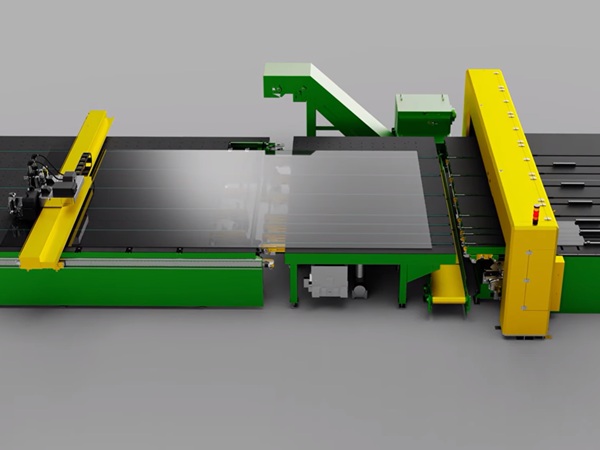

Since August, 2020, FRANZ GYSI AG has been using the VirtualDigitizing software directly on the cutting table. The family business located in Suhr AG, can look back on a long tradition of being a specialized trading, assembly and production company in the field of industrial fittings, seals and fluoroplastic parts.

Conclusion: In addition to cost and time savings, they can now document and use their residual materials much more efficiently.

// Statement from division manager for sealing technology - Mr. Reto Wermelinger

"When cutting gaskets, the problem of recycling residual material arose again and again. In the case of complicated shapes, the zero point on the cutting table could only be determined with great effort and an optimal use of the material was difficult. This motivated us to look for a new solution and we found it with SOFTSOLUTION", says Mr. Reto Wermelinger.

Until now, the creation of templates using a digitizing table has been a time-consuming and cost-intensive process - involving many steps. With the VirtualDigitizing software, company employees generate tangentially smoothed DXF files in no time at all and residual material can be perfectly recorded and utilized on your cutting table.

The easy handling of the software enables the company to quickly digitize the placed remnants with pinpoint accuracy by means of photo scan on the CNC table. Thus, even complicated shapes can be defined and optimally cut with just a few clicks.

The decisive advantage:

// Better utilization of residual materials

// Faster capture & documentation of the remnants / templates on the cutting table

// Simple contour recognition and detection of existing seals

600450

600450

Add new comment