Date: 29 March 2021

2020 was a year that, despite the global crisis caused by the Covid-19 pandemic, highlighted the stability and dynamic approach of the Fenzi Group even against the backdrop of a very complicated situation. Fenzi, in fact, successfully ensured continuous production and ongoing supply of its products worldwide.

Like the rest of the glass industry, the Group faced economic and production setbacks from the end of the first quarter 2020, as the pandemic led to partial or complete closures all over the world, but it successfully optimized its production in order to meet customer needs as flexibly as possible, relying on its versatile organizational structure. “The Teams at all our plants” – comments Alessandro Fenzi – Group CEO “have been crucial, together with all our partners, in successfully coping with a unique historic moment, from which we all want to move on, stronger and with the desire to focus even more energetically and passionately on innovation and sustainability in the world of glass.”

2021 began with great uncertainty, with the world economy weakened after a year of the COVID-19 pandemic, and is currently balanced precariously between new waves of infection and the hope that we can now leave this difficult period behind us. In such an exceptional year, our subsidiaries have given us a world view and acted as strategic observation points for the sector, and we are confident that the international glass industry will be able to make the most of every opportunity for recovery in all areas of activity by cohesively tackling all the critical issues in the supply chains of many sectors directly or indirectly correlated to the glass industry.

Fenzi Italy, innovation non-stop.

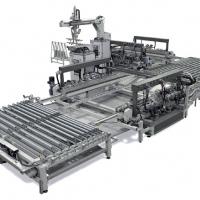

The Italian headquarters of the Group made new investments in 2020, proof of a dynamic approach which the company has every intention of maintaining in the coming years. Looking ahead to Transition 4.0, significant projects have been launched with the ambitious objective of focusing on new production technologies, automation and digitization of the company.

“Always looking ahead, we have made the most of these difficult months of the pandemic to work on new projects and product developments, improving and extending their applications with heightened attention on greener solutions. The best way to celebrate Fenzi’s 80th birthday in 2021 and meet the year head-on with the necessary strength and commitment to get back on the road to rapid growth, not only in Italy but worldwide”, says Matteo Padovan, MD of Fenzi SpA.

Alu Pro and Rolltech, warm edge no limits.

There is a growing demand for high-performance insulating glass components and in particular warm edge specers, solutions for maximum energy saving that can significantly reduce energy and heat dispersion from windows. Despite the current difficult global situation, the warm edge market has not suffered any downturn, thanks to the important contribution of this technology in terms of sustainability and human wellbeing at a time when living spaces have taken on a new role in our daily lives.

In Europe, at the Alu Pro and Rolltech plants, large-scale production of the latest generation hybrid profiles continued throughout 2020 for our customers worldwide who maintained a constant IG production volume, supplying a building sector that has fared better than many others during the pandemic.

With renewed interest in energy efficiency and new green building incentives, being able to count on a unique range of products and technologies to produce any type of insulating glass translates into a significant competitive edge and really does make the difference in terms of end product quality.

“Despite all the difficulties faced during the pandemic – comments Marco Del Bianco, MD of Alu Pro – the demand for our spacers has remained high and, in some markets has not even been affected, most notably for the 3 products -- Multitech, Chromatech Ultra and Thermix -- which are currently the warm edge profiles most widely used worldwide by the insulating glass industry and window and door frame manufacturers.”

Smart technology for digital printing on glass.

The strong interest in digital technologies did not slow down in 2020, in fact digital glass printing, in particular Tecglass printing, continued to develop fast and maintained a positive trend also during the pandemic.

“5 years on from our entry into the Fenzi Group, thanks to the synergies developed and the strategic focus we have acquired, we have become a go-to hub for digital printing on glass and we are confident of consolidating this position in 2021 – says Javier Fernandez, founding partner of Tecglass together with Manuel Ramos – “We have an extremely versatile product range which enables us to cater to a host of diverse glass processing needs, from “Single Pass” technology for the automotive sector, optimized for all types of production process (press bending, sag bending, silver hiding), to extremely competitive printers for architecture developed to offer maximum glass decoration performance for glass processors who have not yet switched to digital.”

Ongoing expansion in China.

In 2020 China was quite a different story, with economic growth concentrated in particular in the last quarter and an impressive capability to tackle the pandemic which saw the entire country and also the glass industry react and recover immediately after the lockdown.

Fenzi China therefore consolidated its position without significant changes compared to the past: “We’ve seen a generalized growth in market shares in all our production sectors”, confirms Stefano Pozzi, MD of Fenzi China, who continues: “Although there is some concern due to fresh Covid outbreaks in some areas of China, we expect to grow in 2021. The forecasts for the Chinese economy remain encouraging. We will continue to focus on the products that have always distinguished our brand and we will strengthen sales and production capacity in our key sectors, which are mirror-backing paints, sealants and all the insulating glass technologies.”

In North America the one-stop shop is a winner.

A strong market, already recovering at the beginning of 2021. The American glass industry has held up in the face of the global crisis, despite the well-known difficulties that have brought many construction sites to a standstill, and has successfully recovered, demonstrating its ability to put all the necessary safety measures in place to cope with the situation.

Considering the predicted realignment of the commercial building sector, which has seen a slight drop, and the upturn of residential building, Fenzi North America, the North American branch of the Group, is focusing on a 360-degree offer for customers and the trade, providing a technological hub for glass processors that can supply everything they need for the use of glass in architecture, interior design, household appliances and in the automotive sector -- one single partner offering customers products and services for the many projects currently in progress.

“We are facing an emergency situation throughout North America which, as in the rest of the world, has changed the way we interface with our customers. However, we are always very close to all our partners, offering easy, flexible solutions to ensure quality results and lessen the risk of problems on-site. Our new technologies allow our team of experts and technicians to continue to build the same level of trust that has enabled Fenzi to become a leader also in the North American market. We provide full support for a diversified and unique product range with the emphasis on quality, thus optimizing the investments of both glass processors and end customers”, underlines James Rodo, Managing Director of Fenzi North America.

New growth prospects for South America.

Although Latin America is one of the emerging regions worst hit by the economic downturn caused by Covid-19, our specific market is one of the exceptions; the sales volumes recorded in 2020 were satisfactory, despite being smaller than the previous year, with operators working at full capacity.

“Some countries in the region have recovered more quickly than others, as they managed to rapidly re-establish their production levels – says Pablo Soifer, MD of Fenzi South America – other countries are still feeling the effects of the pandemic but we are optimistic and confident they will return to normality in the short term. Planning during a pandemic is difficult. Plans can change at short notice. Considering the autumn of 2020, in 2021 we expect to recover at least the volumes of the previous years. As this is a region of emerging economies, the growth prospects for each of the countries for the coming years are encouraging. This year we celebrate 25 years of company operation in this area and, as in the past, we will continue to support the development of insulating glass, offering extremely competitive and high-performance solutions such as the Fenzi warm edge line of spacers and sealants.”

Low emission technologies for Fenzi Belgium.

In line with the decisions of the European Union to further reduce CO2 emissions by 60% by the end of 2030 and in the spirit of new investments in a greener economy, the production center of Vilvoorde, in Belgium, specializing in mirror-backing paints and organic glass decoration paints, continues to work on expanding the range of VOC-free paints and products.

“As always, our advanced research laboratory is committed to developing solutions designed to maintain the high-performance levels which our customers expect, consistently reducing the environmental impact of the paints – underlines Piet De Vos, Mirror Paint&Solution Business Unit Director of Fenzi Belgium – The pandemic has caused a slowdown in the European mirror production market due to the lower availability of glass and less demand. At the beginning of 2021 we are seeing a huge price increase for essential raw materials used in traditional mirror paints. To tackle this situation, we are working on new products with a special focus on water-based products which will help our customers achieve new quality standards at competitive costs, with a significant reduction in VOC values.”

10 years in Russia for Fenzi and Alu Pro, in the spirit of uncompromised quality.

In addition to the Covid-19 pandemic, 2020 was also the year of significant depreciation of the ruble for the Russian Federation, another factor that significantly affected the economy. However, the market reacted energetically, in particular the construction and glass sectors where business continued as usual, with volumes reflecting those of 2019.

“Despite these two negative factors, our market share improved all round – confirms Francesco Costa, MD of OOO Fenzi and OOO Alu Pro – Many sectors struggled to maintain high quality and service levels and continuity of the supply chains due to high infection rates in the workplace. Neither of our plants had to interrupt production and there have been no customer supply problems. We recorded a very important increase in our market share, in terms of both profiles and sealants, in particular the group’s warm edge solutions like Chromatech Ultra, Multitech and Butylver TPS. In sealants for insulating glass we continue to be the go-to partner for customers looking for uncompromised quality and 100% polysulfide sealants. Thanks to the significant commercial developments in the paints sector, ongoing business with mirror manufacturers and glass decoration specialists for architecture and interior design, and the strengthening of our automotive partnerships, we can look confidently ahead to the future.”

600450

600450

Add new comment