Date: 12 April 2021

HEGLA is a well-known supplier of machinery and software for flat glass processing. In order to meet the requirements of future markets, the possibilities of digitalization and, for example, new processes for functionalizing and structuring glass surfaces, the company founded an innovation center: "HEGLA New Technology". The focus here is working on new solutions and innovation projects, away from day-to-day business with appropriate freedom.

“As a machine manufacturer we are driven by our daily business. We have every machine in our catalog, but rarely the standard machine is sold. To be a powerful, sustainable partner to the European glass industry HEGLA needs to be able to produce batch size 1 very efficiently“, says Dr. Markus Schoisswohl, CEO at HEGLA New Technology.

Asset Administration Shell for the Digital Twin

At the SPS 2019 he ran into Markus Kiele-Dunsche, who is Innovation Manager for Engineering and Automation at Lenze. Back than Lenze presented its approach to realize a Digital Twin with the Asset Administration Shell and Markus Schoisswohl, searching for applications of the shell was totally enthusiastic about the concept.

His thoughts were: What if I could get all relevant machine data fully automatically? That would be amazing, wouldn't it? Then I would reduce the effort I had before to virtually zero. Said, done.

Data integration without effort

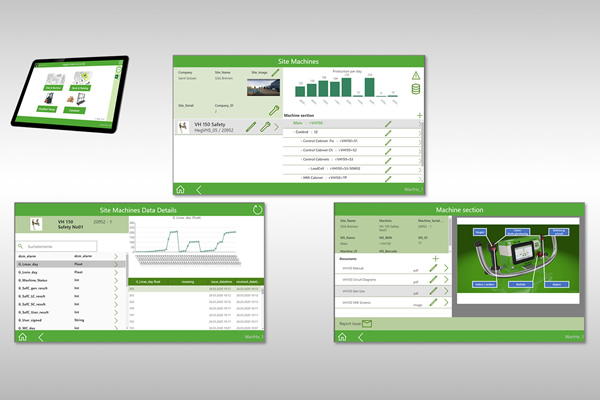

“And that's exactly what we've done,” he explains. “We have created an application called Shopfloor Assistant, which is intended to support production in the glass industry. Here we integrated Asset Administration Shell with Lenze´s help. Markus Kiele-Dunsche recaps the approach: “It took about a month, with some online meetings. And then the whole thing was up and running. HEGLA had built a mechanism that allowed automatically to integrate information of the Asset Administration Shell. The implemented Digital Twin has proven its worth.”

Complete structures including passive AAS parts could be integrated automatically. The benefit: Normally you would have to create the structure and content manually and if we imagine a complex machine structure, with 100 to 150 items, from different suppliers with different data structure, the effort for data integration which is normally tremendous reduces to nearly zero.

Jointly developed: HEGLA and Lenze

600450

600450

Add new comment