Date: 13 January 2016

Two different calculation methods are available in RF‑GLASS: Local calculation of individual glass surfaces, without regard to the surrounding structure Global calculation of the entire structure, with regard to interactions among glass surfaces and the surrounding structure It is possible to create all glazing types in the module; this means not only single layer glass, but also laminated and insulating glass.RF‑GLASS provides an extensive material library including all common types of glass, foil, and gas.The calculation is performed according to the following standards:

- DIN 18008:2010-12

- TRLV:2006-08

Program Features

- Design of single layer or laminated glass as well as insulating glass with intermediate gas layer

- Design of curved glass

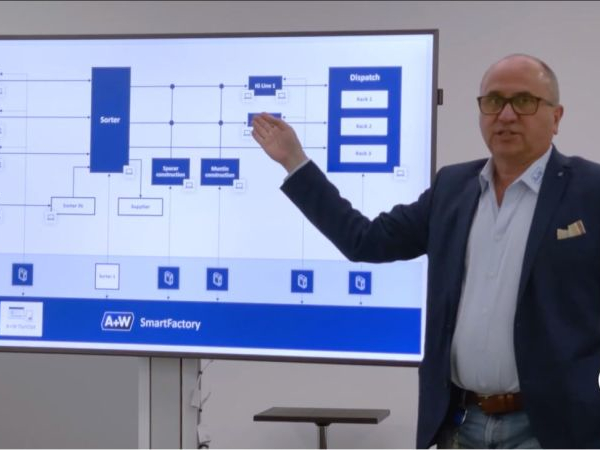

- Option to select either local calculation without regard to the influence of a surrounding structure, or global calculation with regard to the influence of an entire structure

- Limit stress analysis according to DIN 18008:2010-12 or TRLV:2006-08

- Classification of loads into load duration classes

- Extensive material library including all common glass, foil, and gas types in compliance with the standards DIN 18008:2010-12, E DIN EN 13474, and the regulation TRLV:2006-08

- Optional consideration of shear coupling of layers

- Consideration of climatic loads

- Calculation according to the linear static analysis or nonlinear analysis according to the large deformation theory

- Stress analysis, the ultimate limit state design, the serviceability limit state design

- Graphical representation of all results in RFEM

- Possibility to filter results and color scales in result tables

- Direct data export to MS Excel or OpenOffice.org Calc

Input

First of all, you have to select the surfaces for design (using the select function). The geometry of a glass pane and loads are imported from the RFEM model.

Then, it is necessary to decide whether the calculation should proceed without influence of the surrounding structure (local calculation) or considering this influence (global calculation). If you select the local calculation, each surface selected for the design is detached from the model and calculated separately.

The global calculation considers the entire structure including entered glass panes. All glass composition data and glass properties of individual layers are to be defined in RF-GLASS input windows. You can select the layers of type glass, foil, and gas. It is possible to transfer the respective material directly from the library covering a large number of materials.

All parameters of individual layers including their thicknesses are editable. In addition, you can create a number of various compositions in RF-GLASS, which allows you to design different types of glass together.

For insulating glass, you can consider external loads as well as loads due to temperature, atmospheric pressure, and altitude changes for the analysis. The module calculates these loads automatically on the basis of climatic load parameters. If you select the local calculation type, it is necessary to define line supports, nodal supports, and boundary members of the surfaces in RF-GLASS. These supports and members are considered in RF-GLASS only and have no influence on the model created in RFEM.

Calculation

The global calculation assigns the stiffness determined by means of the selected composition and the glass geometry to each surface. Then, the calculation proceeds using the plate theory. It is possible to select whether the shear coupling of layers should be considered.

In the case of the local calculation, you can further specify 2D or 3D calculation. The 2D calculation means that single layer or laminated glass is modeled as a surface and the calculation of its thickness (using the plate theory) is based on the selected composition and glass geometry. Similarly to the global calculation, you can optionally consider shear coupling of layers.

The 3D calculation uses solids in the model to substitute each composition layer. In this way, results are more accurate but the calculation may take more time.

It is possible to model insulating glass only if local calculation is selected. The gas layer is always modeled as a solid element, so it is necessary to design individual insulation glasses separately from the surrounding structure. The calculation applies the ideal gas law (thermal equation of state of ideal gases) and the large deformation analysis.

Results

After the calculation, results are displayed in clearly arranged result windows. Thus, you can easily find the maximum stress ratio. The stress diagram by composition is displayed as well.

Moreover, RF-GLASS shows the parts list and the gas pressure of insulating glass. It is possible to display the results graphically in the RFEM model.

Both input and result tables of RF-GLASS including graphics can be added to the RFEM printout report. In addition, it is also possible to export all tables to MS Excel or OpenOffice.org Calc.

600450

600450

Add new comment