Date: 27 June 2023

With more than 50 years of experience in glass technology and production, Ciraylar has become one of the largest producers in the region in the production capacities of float glass, heat-insulated double glass, tempered glass, and laminated glass.

When tempered glass is produced, it undergoes a rapid heating and cooling process, which creates compressive stress on the surface while the core remains in tension. However, if precise optical or aesthetic requirements are crucial, specialized glass types or additional processing steps may be necessary to achieve the desired level of performance.

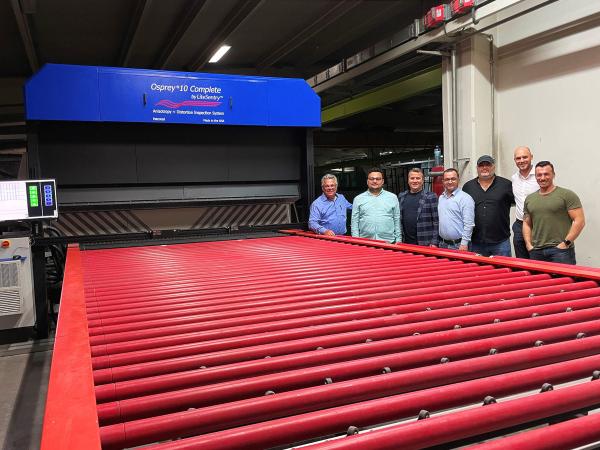

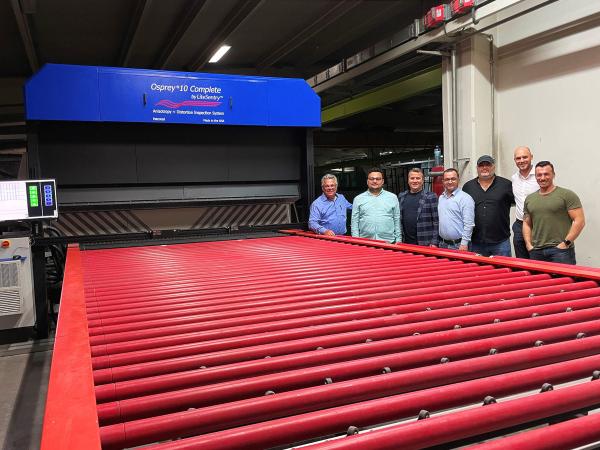

To meet these high-quality standards with tempered glass, the Turkish company has invested in a 2440 mm horizontal Osprey 10 Complete from LiteSentry-Softsolution, which is the only system on the market that measures both optical distortion and anisotropy. In addition, each glass lite/batch is measured and the data is automatically recorded and stored in the software.

“The Osprey systems allows us to control the tempering quality of our tempered glasses at all times reliably. This gives us security and proof , that we only deliver good quality glass according to our customers requirements / the standards. With the report function we can provide our customers with detailed reports and prove the quality of production. We look forward to forwarding this benefit to our international customers.”, says CEO Fahrettin Ciray

600450

600450

Add new comment