Others also read

| The paper discusses some essential findings of two recent research studies on the durability and service life of structural silicone glazing sealants and structures.

| As digitalization becomes a strategic discipline in almost all enterprises and industries, the glass processing business is no exception.

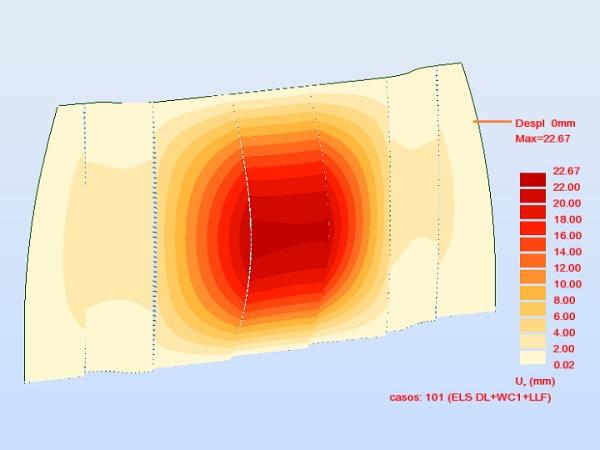

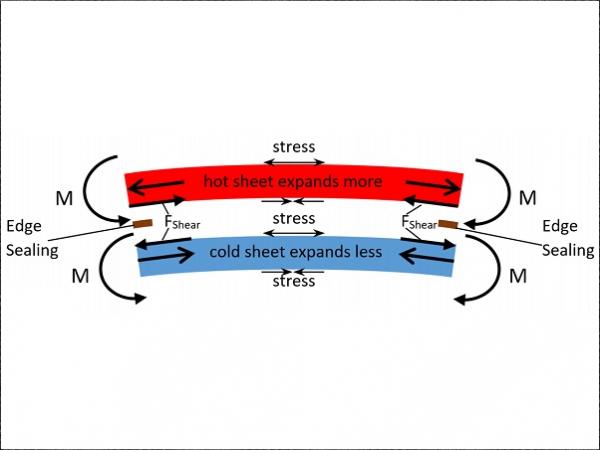

| Warm-bent laminated glass is obtained by elastically curving glass plies against a constraining negative mould and by performing, in this condition, the lamination process in autoclave.

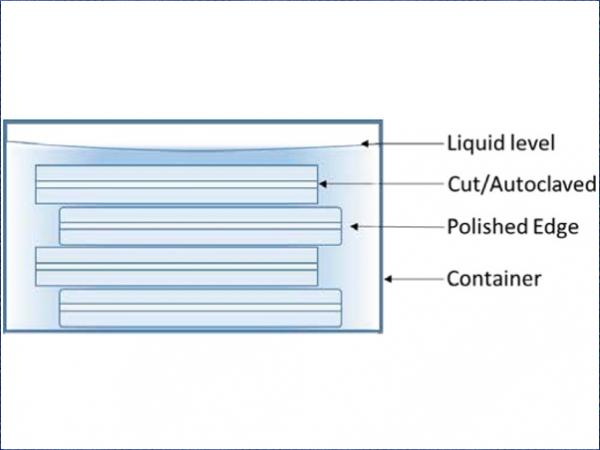

| This paper will present exposure protocols including natural weathering, sealants, salt fog and immersion that are used to determine the edge stability characteristic of laminated glass configurations.

| Are you considering adding insulating glass products to your production mix? Or are you thinking of reconfiguring your current equipment to deliver new and better services to your customers?

| The museum “La Maison des Fondateurs” in Le Brassus, Switzerland will represent the watch making manufacture Audemars Piguet. Audemars Piguet stands for the finest quality, precision as well as innovation based on traditional watchmaking expertise and craftsmanship.

| This paper aims to present the different type of modulus data that have recently become available in terms of conventional load scenarios, and analyze the effect of different modulus data sources on effective thickness.

| Glass balustrades are a common application of laminated glass, wherein the glass panel acts as a structural member that is required to sustain lateral design loads as stipulated by building regulations.

| The reduction of greenhouse gases is one of the most important goals of the international climate policy. Today, roughly one third of all greenhouse gas emissions is created by urban population.

| In several standards such as EN 1288 test scenarios for the determination of strength of glass is described.

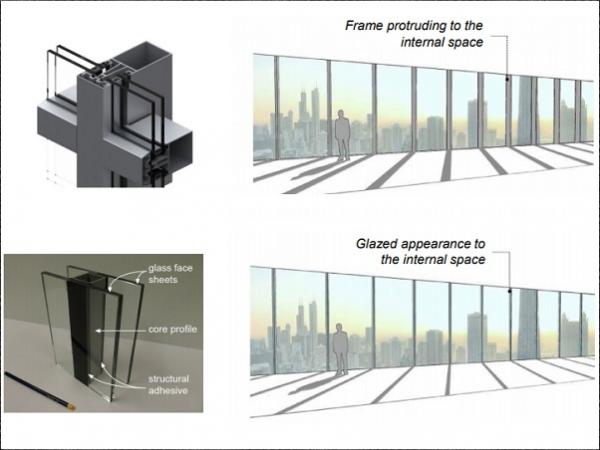

| Glass panes adhesively-bonded to structural profiles allow for the design of stiff, robust and transparent sandwich structures.

| A pedestrian glass bridge, located at the TU Delft campus site, is being designed by the TU Delft Glass & Transparency Group.

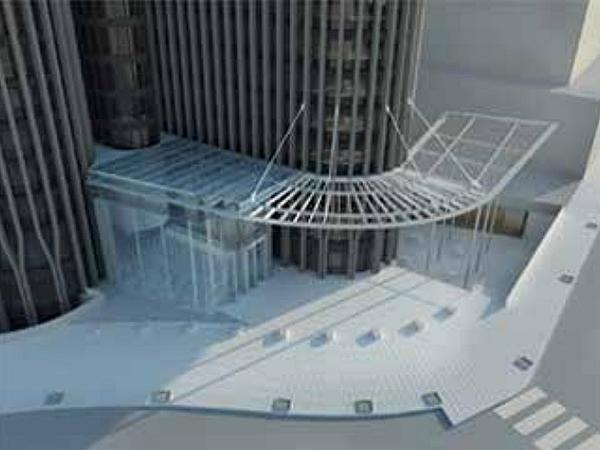

| The refurbishment of Hall access involves the complete demolition of existing access for the construction of a new lobby with greater transparency. To get this new image, the architect choose a solution in structural glass, without other structure.

| In 2015 a pavilion mainly built of glass was finished. The building contractors themselves planned it as a transparent extension of their detached house to the garden.

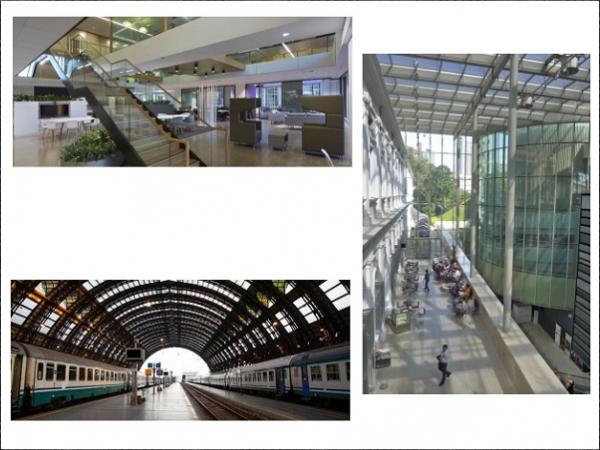

| In the last decade there has been a trend in Architecture to design façades in which all structural elements are made of glass. This trend has also extended to other parts of the building such as rooflights, staircases, etc.

| 111 Main presented a unique challenge of façade design.

| This paper aims to answer a simple and elemental question: how do we qualify and quantify thermal comfort in highly glazed spaces with diverse occupants’ use and expectation?

| The Vacuum Insulated Glazing (VIG) is a unique thermally insulating window technology that can provide significant advantages over the conventional insulating units.

| The combination of the double-skin concept with unitized systems made current typologies of double glazed units possible.

| It is well known that laminated safety glass (LSG) is a material that is specifically processed because of its composition.

| During a recent project to understand the ability to use Transparent Structural Silicone Adhesive (TSSA) via linear bonding for cable wall fittings, a unique aspect of the material indicates a potential novel method for cold bending glass.

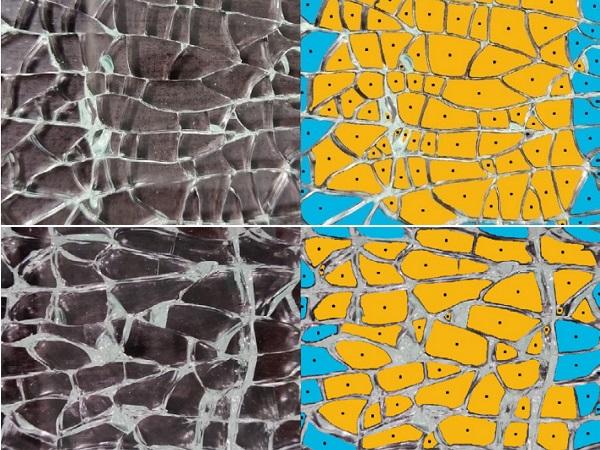

| The fragment count in the standardized fragmentation test in the standard EN 12150-1 is the way to define the safety level of tempered glass and a way to also get an indication about the stress and strength level of the tempered glass.

| Glass distortions may cause objects to appear irregular and out of focus when observed through a distorted glass panel.

| The New Hype in Top End Architecture – an Examination of Latest Product Developments and Projects