First presented at GPD 2017

Walter Haase1, Marzena Husser1, Werner Sobek1,2

* Research supported by the Federal Institute for Research on Building, Urban Affairs and Spatial Development within the Federal Office for Building and Regional Planning, Germany (research project: “TN technology for architectural applications”) and by Baden-Württemberg Stiftung GmbH, Germany (research project: “i³: intelligent, interactive, integrative solar control glazing”)

1 Institute for Lightweight Structures and Conceptual Design (ILEK), University of Stuttgart, Pfaffenwaldring 7 and 14, 70569 Stuttgart, Germany

2 Werner Sobek Group GmbH, Albstraße 14, 70597 Stuttgart, Germany

Abstract

Glazed facade units must satisfy numerous criteria. In addition to allowing an unobstructed view of the exterior they should also provide protection from direct sunlight and the associated heat transfer. In order to optimize the performance of glazed facades under varying conditions, much effort has been directed towards the development of adaptive glazing systems based on smart materials or smart mechanisms. This article will outline the functional principles and visual properties of a liquid crystal based system.

By modifying conventional liquid crystal technologies used for display applications and upscaling the pixel size to an architectural meso scale a switchable glazing system with unique and promising characteristics was developed and investigated by the authors. The advantages and the most promising fields of application of this adaptive glazing system will be presented herein.

1. Introduction

The function of the building envelope is to act as the interface between the interior and exterior environments. The performance of the glazed sections of the facade is essential for providing the maximum possible comfort for the building occupants, while minimizing the energy and resource demands of the building.

Since both the external climate conditions as well as the user demands from the interior vary considerably over time, an interface with constant properties is bound to be less than optimal. Instead, an adaptable “building skin” is required – one which can regulate light and energy flows and prevent glare effects to maintain the highest possible level of efficiency under all conditions.

Research and design have been underway for some time in the field of adaptive window elements for building envelopes, in both university and industrial settings. By modifying conventional liquid crystal technologies used for display applications and upscaling the pixel size to an architectural meso scale a switchable glazing system with unique and promising characteristics was developed and investigated by the authors.

2. Controllable Liquid Crystal Based TN-Glazing - properties

The vast majority of current large scale television displays is based on liquid crystal (LC) technology [1]. LC-displays (LCD) are substructured into hundreds of thousands of pixels which individually act as light valves to control the transmittance of the screen‘s backlight. Each pixel comprises three subpixels equipped with red, green, and blue color filters. By altering its transmittance each sub-pixel can be controlled to produce the desired intensity of color and thereby display color images.

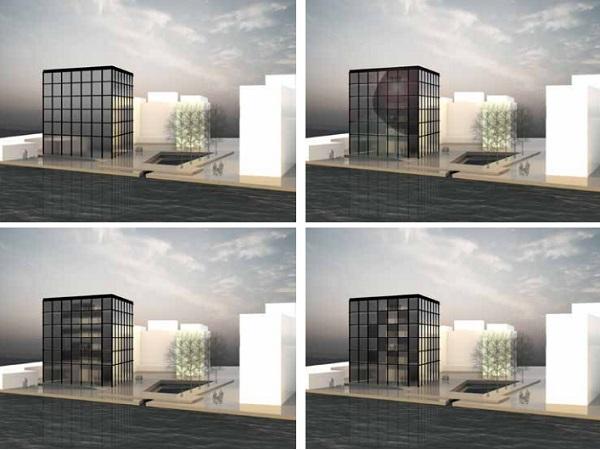

The simplest technology to achieve displaying images (grayscale) is the twisted nematic liquid crystal cell (TN-cell). A very thin layer of nematic liquid crystals (only a few microns thick) is contained between two glass substrates. Two conductive layers are necessary on the inside surfaces of the substrates. So-called orientation layers at the boundary surfaces of the liquid crystals serve to selectively orient the rod-shaped crystals if no voltage is applied.

If polarizers are applied to each substrate on the outside, it becomes possible to influence the transmittance of light and energy. The polarizers are usually oriented at 90 degrees to one another. Through the application of a small voltage (~3-15 V) to the two conductive layers, the orientation of the liquid crystal molecules is affected and the intensity of the transmitted light can be controlled. The investigated TN-cell in “off” and “on” state is depicted in Figure 1.

The idea of scaling up the pixels of a TN-cell to dimensions suitable for architectural glazing applications is not new [2]. However, thus far it has not been possible to manufacture an adaptive window unit based on the TN-cell technology with sufficient long-term durability. The temperature- and UV-stability of the foil polarizers and their sensitivity to moisture have been the primary obstacles. Improvements on foil polarizers now seem to permit the use of TN-cell technology as an adaptive element of large scale glazing units [3][4].

As in conventional liquid crystal displays, the conductive layers of the TN-cell can be structured in a laser or photolithographic process. In this process the cell is subdivided into pixels that may be switched individually. Every pixel is connected to the control unit via a transparent conductive path (transparent wiring) which generates a thin gap between adjacent pixels. The conductive path cannot be darkened. Such a device is defined as TNmodule.

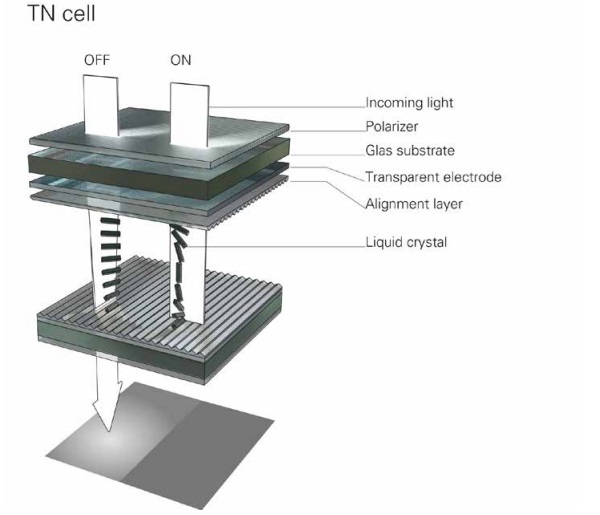

Due to the filter effect of the polarizers and the reflection and absorption of the glazing itself, a TN-module reaches a maximum light transmittance of about 37 %, making it comparable to other sun protection glazing systems. Though, the pixel transmittance can be varied down to less than 1 %. The transmittance of the module is higher and greatly depends on the gap width and the total gap area of the module. Decreasing the gap area is therefore the aim for optimizing the pixel layout. The spectral transmittance of a single pixel of the TN-module, as measured with a spectrometer by the authors, is shown in Figure 2.

For optimizing the properties of the insulation glass unit (IGU) with integrated TN-modules, the fundamentals of energy flux through a window must be considered. Radiative heat flux represents approximately 2/3 of the energy flux within a window and is dependent on the material characteristics of window panes and coatings [5]. Due to the high absorptance of the switchable cell, it heats up to approximately 70 °C – 80 °C.

In order to prevent heat transfer from the cell to the room, the application of additional glass coatings is advisable. On the basis of measurements in a sun simulator and simulations done with the software Window / Optics [6] it could be shown that the temperature of the inner pane of an insulation glass unit equipped with TN-modules and provided with a selective coating does not exceed the temperature of a common double glazing significantly [4].

3. Prototypes

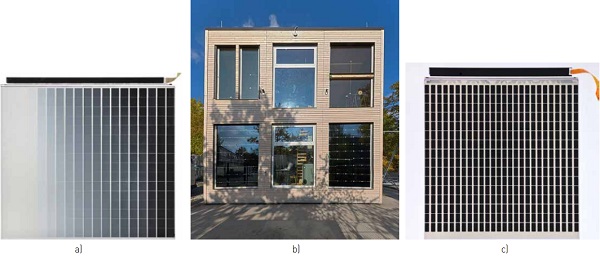

The authors succeeded in manufacturing two prototypes of substructured switchable insulation glass units (SIGU) [7]. The functional components (TN-modules) were produced by the company BMG MIS GmbH Luminator Technology Group according to the specifications defined by the authors. The glass panes for the IGU were delivered by Okalux GmbH according to the layout defined by the authors. Appropriate mounting parts have been designed to fix the TN-modules to the inner surface of the outer glass pane of the IGU.

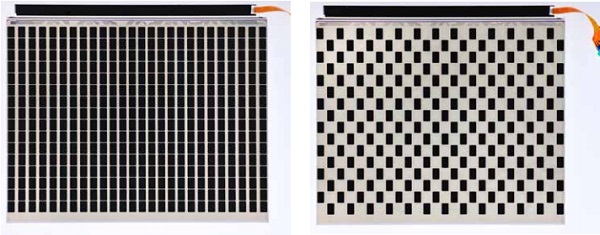

Two different TN-module types have been investigated by the authors. TNmodule type 1, as shown in Figure 3, exhibits a pixel arrangement with 26 columns and 16 lines (amount of pixels: 416). The individual pixels may be driven in the „off“ or „on“ state. Different transmittance values of this type of glazing are to be achieved by displaying different image patterns. The vertical nonswitchable pixel gaps mainly define the minimum overall transmission of the module. In these gaps, the contacting wires are guided to the control electronics, which is located at the upper module edge.

The slight reduction of the amount of pixels per module led to TN-module type 2 (Figure 4.). In 19 columns and 16 lines there are 304 individually controllable pixels which can be switched in 16 gray scale steps each. The pixel gaps could be reduced significantly for this type, which leads to an improved dark state of the glazing.

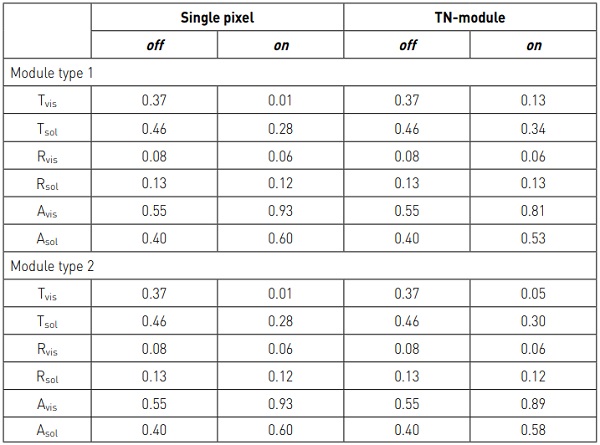

The spectral transmittance of one single pixel of both types of modules and the appropriate values for the modules are shown in TABLE 1. Spectral properties were measured using a spectral photometer (see Figure 2). Photometric (index: vis) and radiometric (index: sol) properties have been calculated then according to DIN EN 410 [8]. The minimal transmittance of module type 1 (Tvis=13 %) is significantly higher than of module type 2 (Tvis=5 %) [9]. Further development of the pixel layout aims at achieving a dark state of the module of about 2 %. Daylight simulations [10] for Stuttgart confirmed that no further glare protection would be necessary for a TN-glazing with this darkening efficiency.

Transmittance, Reflectance And Absorptance Values Of The Pixel Area And The Modules For Both Types Of Tn-Cells

4. Facade test facility

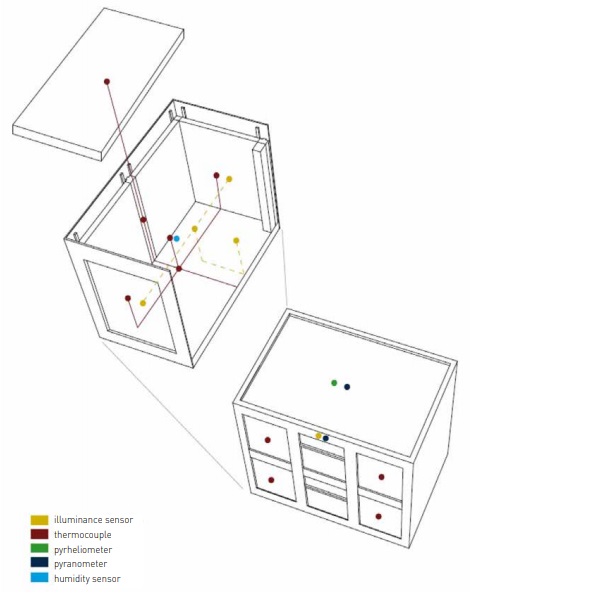

For further investigation of the influence on the indoor climate, the energy consumption for room conditioning, the daylight provision and the glare protection, the SIGU equipped with TN-modules have been implemented in the south facade of a test building in StuttgartVaihingen.

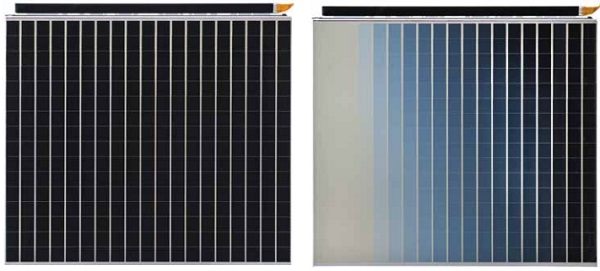

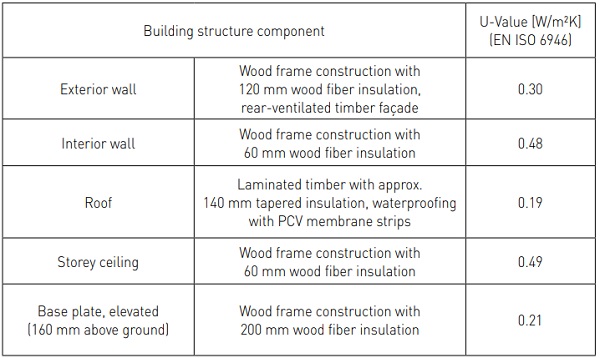

The two-storey timber building at the University of Stuttgart includes four test rooms with dimensions of 2.00 m x 4.20 m x 2.70 m (width x depth x height). Each of these rooms can be considered an independent office space. Crucial properties of the construction components of the test building are presented in TABLE 2.

The south facade of the building is designed for easy incorporation of different glazing units. Two test rooms are currently equipped with the switchable glazing units presented in this paper (cell type 1 in room 1, cell type 2 in room 2), as shown in Figure 5. The first insulation glazing unit was equipped with 45 modules of type 1 arranged in 9 lines and 6 columns of modules. The window size is 244 cm in height and 174 cm in width. This arrangement of the SIGU exhibits 18720 pixels. The SIGU in the second room was equipped with 54 TNmodules of type 2 with 16416 pixels.

The facade test facility is provided with measurement equipment for recording the outdoor and indoor conditions. Solar irradiation is detected by means of two pyranometers and a traceable pyrheliometer on the roof of the building. Other weather parameters are provided by a local weather station. For measurements of the visual and thermal conditions in the interior, illuminance sensors, thermocouples and humidity sensors are used. The measurement equipment for one of the test rooms is visualized in Figure 6.

5. The Concept of Control

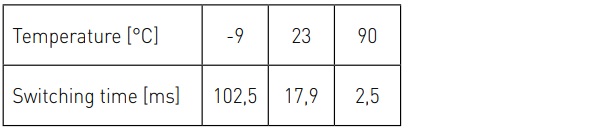

The control strategy applied to each of the switchable glazing takes into account the feasibilities arising from the subdivision in individually controllable pixels and from the quick response time for switching a pixel. Switching times under different temperatures have been measured (TABLE 3). The response time depends on the applied voltage and temperature of the module. Even under low voltage and low temperatures switching from one transmittance state to another does not exceed 103 ms.

The ability for tinting the glazing partially combined with the quick response time allow for controlling daylight and glare protection independently from one another. The high switching capacity allows for following the changes of outside conditions and ensuring the best possible indoor lighting situation. Glare protection may be achieved by tinting the appropriate areas of the glazing. Daylight provision may be adjusted by darkening or brightening the remaining areas as needed.

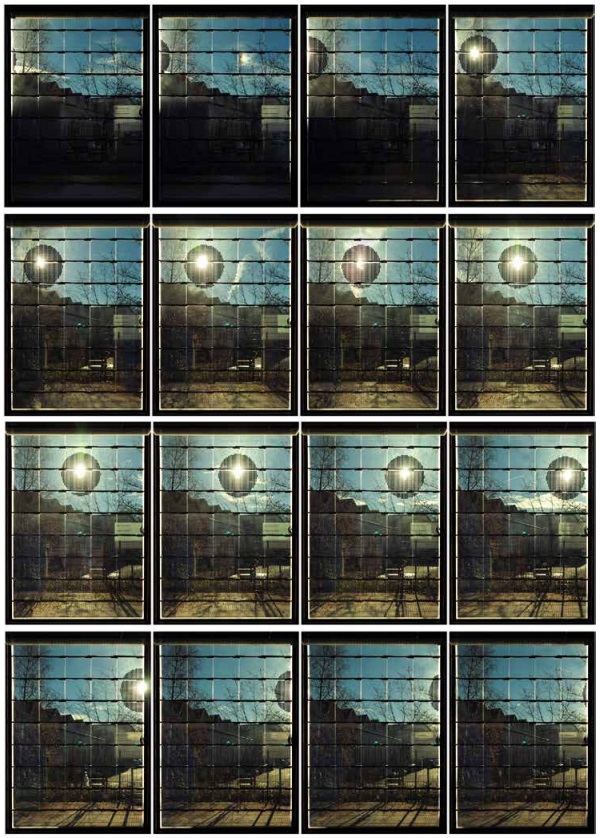

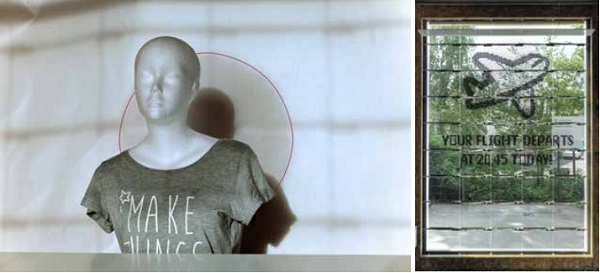

Glare protection is investigated by displaying a circular spot on the window. The algorithm for calculating the position of this spot takes into account the sun’s movement and the occupant’s position in the room.

First measures assumed a fix position of the inhabitant. Therefore, it was sufficient to update the positioning of the spot once a minute to ensure proper shading of the occupant’s head. First tests of the SIGU with TN-modules of type 1with this strategy have been started and led to promising results. The movement of the spot is shown in Figure 7. The shading effect on the direct sun radiation for the occupant is shown in Figure 8.

Figure 9. (right) Displaying information on the SIGU with TNmodules of type 1. View from inside to outside. Phot.: G. Metzger, ILEK

The irradiation intensity at the occupant’s position will be measured using photometric and photographic methods during next steps of investigation. Currently, the reliability of the control strategy could be proved even though it is obvious that glare protection cannot be achieved completely with the TN-glazing of type 1 because of its too high transmittance in the dark state.

Improvements in shadowing efficiency are expected when investigating the TN-glazing of type 2 because of the lower transmittance in the dark state. The main advantage of the TNglazing compared to other investigated glazing types is the possibility of sub-structuring the window area. It allows for an increase in light transmittance by only darkening the necessary spots. In addition, a window equipped with TNmodules offers the occupants a further option because it may also be used as an information display. This effect is shown in Figure 9. Even though the resolution is quite rough compared to LC-displays the potential of this type of glazing is clearly demonstrated.

6. Conclusion

Although both types of the TN-glazing exhibit lower maximum transmittance compared to electrochromic window technology, their performance is promising. First quantitative results will have to be confirmed during the following qualitative investigations of daylight and glare control, as well as their influence on reducing energy demands for room conditioning. Currently, the authors are implementing further control strategies into the facade test facility for in situ evaluations. Automatic detection of the occupant’s position will ensure an enhanced flexibility of the glazing partitioning.

7. Architectural potentials

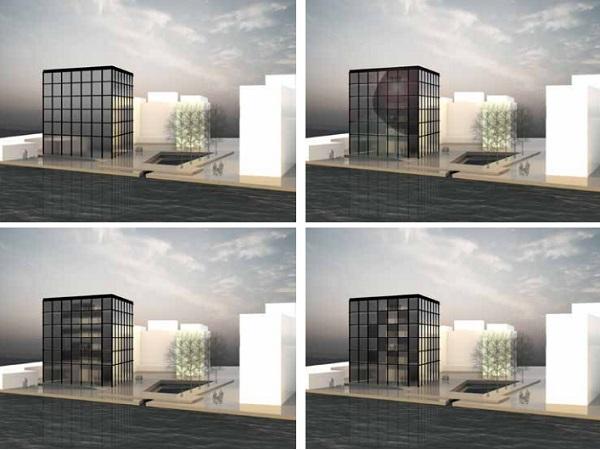

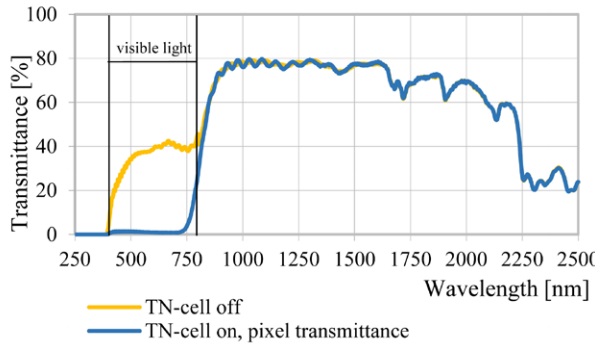

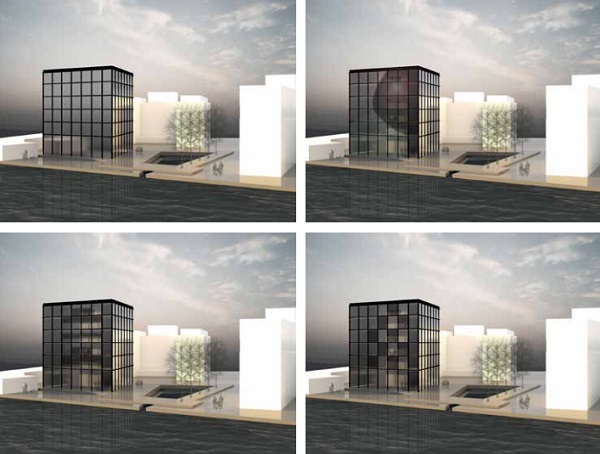

In comparison to conventional facade solutions, the switchable, substructured TN-glazing developed by the authors shows significant advantages. It is characterized by a large switching range and a very short switching time. The possibility of implementing the switchable glazing units in standard framing systems, combined with their minimal connection requirements makes the system perfect for being applied into new building facades as well as for retrofitting existing buildings.

As shown within the first simulations [7], the TN-glazing has the potential to replace conventional insulating glazing units with external shading. The integration of sun and glare protection functions, complemented with an effective controlling, leads to a remarkable comfort improvement. The glare is the main comfort factor which can be influenced by the implementation of the TN-glazing. Moreover, a slight reduction of the building’s energy demand is expected. Additionally to the reduction of cooling energy demand, the reduction of embodied energy and of the resources consumption, compared with common additive facade solutions, are remarkable advantages of the TN-glazing.

Waiving of additive solutions leads to an architecture of simplified expression and complex functionality. The sun protection is no longer a secondary device which has to fill out strictly defined boundaries. The possibility of darkening any required area of the glazing makes the facade flexible and changeable. The position of areas on the facade used for light and energy transmission and to enable visual contact to the outside can be flexibly redefined in dependence on actual needs [7]. The following Figure 10. illustrates several application options of the structured adaptive glazing in a fully glazed facade. The depicted flexibility is only one example for the expected wide application field of this system.

8. Acknowledgements

The work described herein was carried out in the framework of the following research projects: “TN technology for architectural applications”, founded by the Federal Institute for Research on Building, Urban Affairs and Spatial Development within the Federal Office for Building and Regional Planning and “i³: intelligent, interactive, integrative solar control glazing”, founded by the Baden-Württemberg Foundation.

The construction of the facade test facility was supported by numerous industrial companies, above all by Rubner Haus AG - S.p.A., Toshiba Klimasysteme Beijer Ref Deutschland GmbH, TWL-Technologie GmbH, Nimbus Group GmbH, Alcoa GmbH, Paul Bauder GmbH & Co. KG, Okalux GmbH. The companies BMG MIS GmbH and Okalux GmbH supported the manufacturing of the described prototypes. The authors wish to express their gratitude for this support.

References

[1] Chen, R. H.: Liquid Crystal Displays: Fundamental Physics and Technology, New York (2011)

[2] Gläser, H.-J.: Abschirmvorrichtung für Fenster (Shielding for Windows), German patent DT 2155951, date of patent: 8 th March 1973.

[3] Haase, W., Husser M., Kurz E., Rau L. “Schaltbare Verglasung auf der Basis von lyotropen und nematischen Flüssigkristallen (Swichable Glazing Based on Lyotropic and Nematic Liquid Crystals)“, Project Report, Stuttgart, 2014.

[4] Husser, M. et al., “Structured Sun Protection Glazing” in Proc. Engineered transparency. International Conference at glasstec, Düsseldorf, 2014.

[5] Schittich, C. et al., Glass Construction Manual, Birkhäuser, Munich, 2007.

[6] Lawrence Berkeley National Laboratory (LBNL), “Window Optics”, http://windowoptics.lbl.gov/ (Access on: 08 Mai 2017).

[7] Husser, M., Haase, W., Hoß, P., and Sobek, W., “New Possibilities of Sun and Glare Protection with a Structured Switchable Glazing” in Proc. Challenging Glass 5, Ghent, 2016.

[8] DIN EN 410 Glass in Building – Determination of Luminous and Solar Characteristics of Glazing, German Version EN 410: 2011.

[9] Haase, W., Husser, M., & Sobek, W., “Potentiale strukturierter, schaltbarer Verglasungen (Potential of Structured Switchable Glazing)” in B. T. Weller, Glasbau. Ernst & Sohn GmbH & Co. KG., 2016.

[10] Hoß, P., Simulation des Einflusses verschiedener klimatischer Randbedingungen auf die Regelungsstrategie schaltbarer Verglasungen und den Gebäudeenergiebedarf (Simulation of the Influence of Different Climate Conditions on the Building Energy Demands and on the Control Strategies for Switchable Glazing), Bachelor Thesis at ILEK, Stuttgart, 2015.