This paper was first presented at GPD 2015 by Louis Moreau and Franklin Lancaster.

Introduction

Dry glazing with pressure plates and spider fittings have been used for decades. Development in silicone chemistry enabled Structural Sealant Glazing (SSG). This technology triggered an architectural trend where the building envelope conveys a seamless image. Glass panels are mounted side by side, without separation, concealing the supporting structure. The SSG technique requires a lot of operations and quality control and is very difficult to perform on site. It superimposes silicone and aluminum that are already components of structural IGUs. Facade system makers developed ingenious ways to use the IGU edges to allow mechanical connections between glass and the structure as a substitute to SSG.

Systems

Quaternario - Permasteelisa

Principle

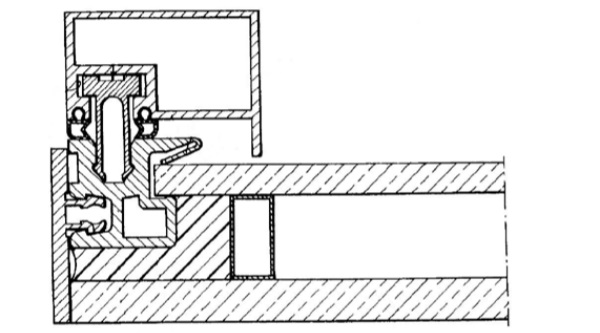

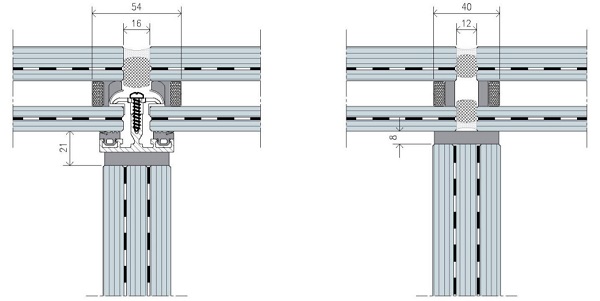

Full perimeter mill finish aluminum frame integrated in the sealant bead. The internal lite is stepped back to provide a large bonding area for the front lite. This assembly can be made on the automated IGU assembly line. The original patented design presented here allows snapping on frame. More recent version provides screwing capabilities.

Challenges

Because of the complex automated assembly and extra equipment required to assemble automatically, very few fabricators can produce Quaternario IGUs. The design of this system requires a large sight line.

Manufacturing

Both inner and outer lites have different sizes and their dimensional tolerance needs to be ±1 mm. Aluminum cutting and mitering are required to assemble the frame. Finally a special silicone application head has to be used to inject the silicone in a narrow opening.

FW 50 SG – Schüco

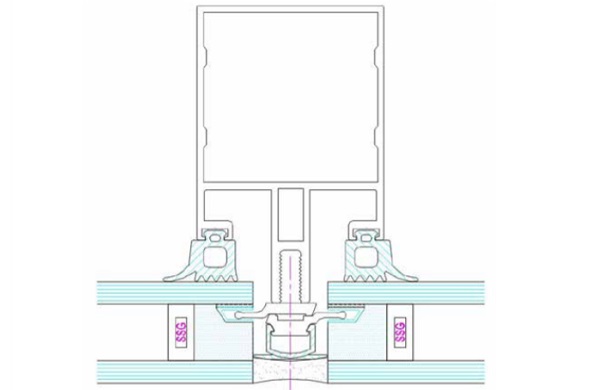

Principle

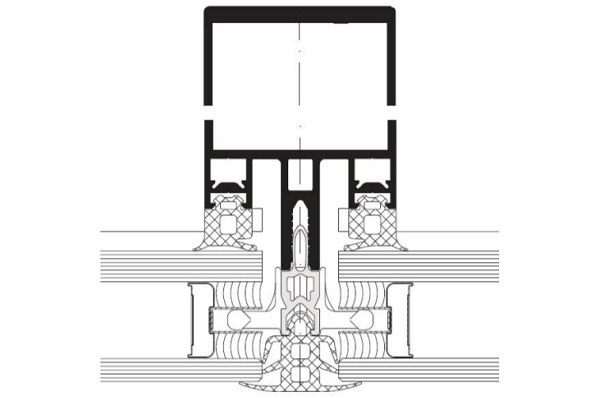

The classic Schüco system uses a special IGU spacer bar that comprises a U channel attached or molded to the spacer box. This creates a continuous channel on the whole perimeter of the unit. Threaded toggles or glazing clips are used to attach the middle of the profile to mullions. Schüco also offers a pocket system.

Challenges

The standard aluminum spacer has thick walls and high thermal conductivity.

Manufacturing

The horizontal top corners assembly requires milling equipment for the spacer. A special silicone application head must be used to inject the silicone in two narrow cavities without filling the middle one.

VGG – Reynaers

Principle

A full perimeter thin mill finish aluminum V profile is attached to the back lite of the IGU. Long and thin interlocked strip inserts into the cavity to attach to the profile.

Challenges

Larger sightline: the profile height (10 mm) is not considered structural.

Manufacturing

Installation of the perimeter extrusion is done manually and is time consuming. During assembly, a double-sided tape is used to hold the profile before and during the sealant application. Foam bead preventing silicone to contaminate the groove needs to be removed after sealant has cured.

VARIO – Eckelt

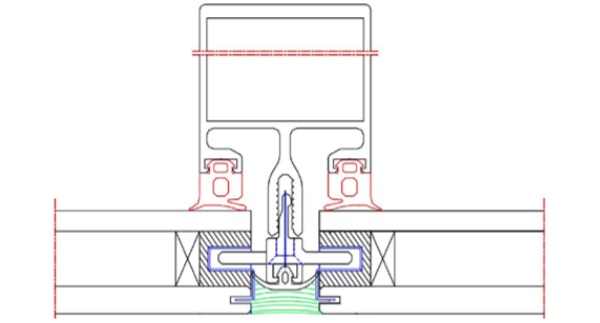

Principle

VARIO uses a 100 X 12 X 8 mm stainless steel U channel that is embedded or suspended in the middle of the silicone joint. Those fixation points are spaced 400 to 600 mm apart on the perimeter.

Challenges

Top horizontal channels can fill with stagnant water.

Manufacturing

The pocket is inserted after normal automated sealant application. Correct positioning of the clips requires a jig and skilled workers. Silicone reflow inside the channel can be awkward.

Skandinaviska

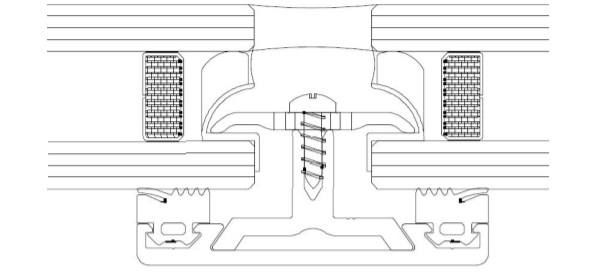

Principle

100 mm waterproof plastic pockets are embedded in the silicone joint and spaced apart from 200 to 600 mm, depending on wind load. Several types of pockets offer shallow or deeper retention area. The IGU is mechanically fixed back to the facade construction by means of the 25-30 mm retractable tabs and a threaded restraint.

Challenges

Fixed 15 mm spacer.

Manufacturing

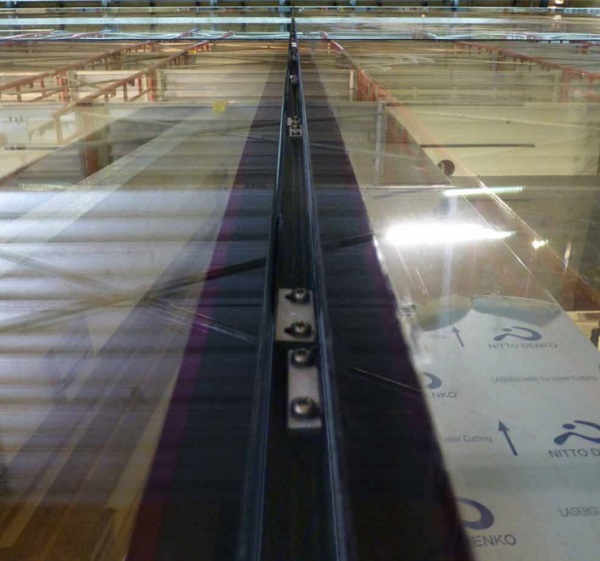

The IGU assembly is done on a normal automatic line assembly. The self-centering plastic or composite pockets are pushed into the fresh silicone at the end of the line. This expels only the clip’s volume of sealant.

Case study

H&M 5th Avenue, New York.

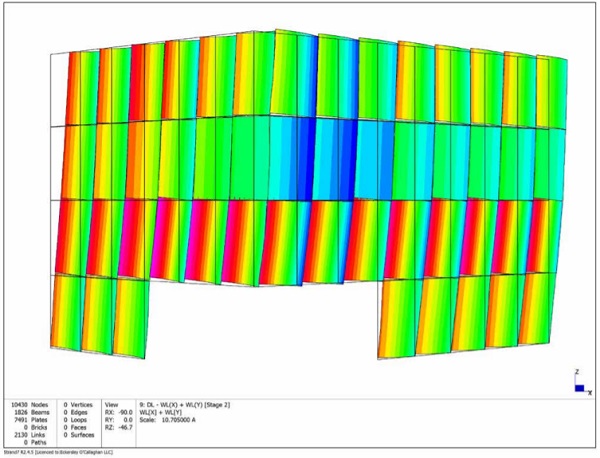

The H&M store was completed in July 2014. It consists of large format insulated units (typically 3.5x2.2 m) supported by structural glass fins. The triple laminated glass fins with a total height of approximately 13.5 m are spliced in two locations and carry the vertical load from the facade IGU panels. The architectural requirements to have minimal and clean sight lines with no discrete point or patch fittings or pressure caps suggested either a fully structural silicone approach or a toggle system.

Whilst fully structurally bonding the facade panels to the glass fins with silicone potentially looks simple, it has several drawbacks such as ensuring sufficient structural bite to transfer the applied loading, large amounts of on-site silicone work and difficult replacement. Beyond the typical drawbacks of a full-fledged SSG system, one of the biggest challenges of this project was lateral drift of the building under wind load. Under this induced movement, the facade panels rotate about their support points, which causes differential vertical displacements in the joint between two adjacent panels. If the facade panels were attached to the fin directly with structural silicone, then the shear force generated in the silicone would be too high.

For these reasons, the Skandinaviska clip system was used to laterally restrain the panels, meaning that all the silicone joints could be low modulus weathersealed type capable of accommodating the required strain. Furthermore, the custom Skandinaviska channel could be structurally bonded to the glass fins in the factory under controlled conditions, ensuring a high quality bond, and delivered to the site ready for the IGU panels simply to be mechanically fixed in place. This led to a very quick installation process and high quality finish with minimal sight lines.