First presented at GPD 2017

Abstract

The Asia-Pacific region has seen unprecedented growth over the past decade, both in terms of economy and population. As the growth in this area occurs, the demand for additional high density residential and office space has also increased, resulting in record numbers of high-rise buildings being constructed. The development of the built environment in this region has largely occurred in coastal areas, which are increasingly vulnerable to disastrous storms, specifically cyclones, also known as typhoons in Asia and as hurricanes in the US.

The Asia-Pacific region is the most disaster prone in the world, and since 1980, these climate-change-induced disasters have been consistently increasing in both frequency and severity. These events can be of such magnitude that the economic stability and growth of highly-populated areas can be threatened. Currently, the curtain wall is seen as the primary barrier to protect a tall building and its occupants from these external threats, in addition to controlling a buildings internal climate and lighting.

This research will examine the buildings that have been affected by cyclone events, buildings that are currently at risk, and steps that have already been taken to combat these threats. Next, projections of future threats will be made, which will emphasize the need for advancements in cyclone resistant glazing technologies and standards. Through these advancements, tall buildings could not only avoid major damage during cyclone events, but also serve as a refuge for local residents.

Introduction

The research project “Cyclone-Glazing and Façade Resilience for the Asia-Pacific Region” has been conducted by the Council on Tall Buildings and Urban Habitat, thanks to a research grant received from Kuraray Trosifol® World of Interlayers. The bond between the contemporary skyscrapers’ architectonic image and glazed construction is evident.

The performances of glass are rising with these buildings, guaranteeing users’ safety. Current, state-of-the-art cyclone-resistant façade technology requirements in the AsiaPacific region have been investigated. In this area of the world, megacities are developing to address the demand for additional residential and office space, which calls for the construction of high-rise buildings.

Highwind storms, called typhoons in the region, represent a serious threat to the economic stability and growth of these markets, and can often claim a high toll of lives when they occur. The building’s envelope is a critical component to its performance during a windstorm. Damage to glazed enclosures, caused by windborne debris during a typhoon, represents a significant contributor to the post-event recovery costs.

The aim of the research was exploring the norms and standards of the major tall building markets within the Asia-Pacific region in order to propose a new general guideline for the design of typhoon-resistant façades in those countries in the future.

The research in this paper focuses on the some of the countries that are the most prone to typhoons in the Asia-Pacific region.

Asia Pacific Region Environmental Vulnerabilities

The World Bank Group in its October 2016 “Reducing Vulnerabilities” East Asia and Pacific Economic Update [1] has shown that both the frequency and severity of disasters in East-Asia Pacific region have been rising since 1980. Over this period, more than 3.5 billion people have been affected by natural disasters, and the region has sustained some US$525 billion in losses (nearly a quarter of total global losses from natural disasters).

Although the number of fatalities have not followed a linear trend, the total number of disasters and the amount of people affected in the EAP region between 1980 and 2015 have been constantly rising. The data also shows a growth in the frequency and intensity of atmospheric events.

This data means that CTBUH has to work with building solutions and technologies in order to reduce the affected population. The World Risk Report [2] has created a World Risk Index, which characterizes the disaster risk for 173 countries. The risk index takes into account natural hazards and the social sphere.

This is calculated on:

- the exposure to natural hazards;

- susceptibility: likelihood of suffering harm;

- coping capacities: the capacity for a country to reduce negative consequences;

- adaptive capacities: the capacity for a country to develop long-term strategies for societal change.

The research community has to increase the amount of proposed technical and societal improvements for the Asia Pacific countries, in order to reduce the negative consequences of natural disasters. Currently, 7 of the 10 most at-risk countries in the world are located in the Asia Pacific region (11 in the top 20) and the East Asia and Pacific region is the most disaster prone in the world [3].

Furthermore “Sustaining Resilience” East Asia and Pacific Economic Update of April 2017 [4] indicates that most of the small Pacific Island Countries are experiencing moderate to strong growth but they are at the same time vulnerable to natural disasters and climate change. More or less every year, these countries are hit by natural disasters. In the “Pacific Possible” program of research on long-term economic opportunities, vulnerability will remain high even with an increased policy focused on disaster risk management. This high level of vulnerability could undermine the development of these countries [5].

Almost all of the standards developed for wind speed and wind pressures for cyclone events are based on a predictive model. This model does not take into account the strongest event in a deterministic manner but in a statistical one. The research community does not have the recorded data from all historical cyclone events. The development of the model has sped up in recent years, taking into account the increasing number of these natural events due to climate changes [6].

“Cyclone-Glazing and Façade Resilience for the Asia-Pacific Region” Research Project

The research methodology has been developed according to the following three steps:

- identification of the severity of the problem presence of tall buildings in typhoon prone areas;

- identification of existing codes – design and test requirements for typhoon resistant façades;

- comparison of Asia-Pacific codes on the matter, and comparison with the most advanced international codes and best practice in the western countries.

The output of the Research is a concise tool for public administrations, for private consultants operating in the Asia Pacific market, for insurance companies, and at the very least, for façades professionals operating in typhoon prone countries field. It is a matrix examining the similarities and differences between international, US, and Asia-Pacific countries codes and standards for cyclone resistant glazing systems.

Technical performance requests, local market minimum requirements in designing, testing, commissioning, and acceptance processes for fast emerging economies is shown. This means identifying what is missing in each regional code and how the various requirements available can be merged to generate a new region wide guideline for typhoon prone façade resilience in the Asia-Pacific Region, which identifies different levels of technical performance in the specific theme.

Typhoon resilience is the capacity for a building to protect its properties and provide safety to occupants during tropical storm events. The social conditions of analyzed fast emerging countries is highlighted though this tool that photographs the current situation, in order to be able to propose actions to be taken for the future.

Identification of the Severity of the Problem – Tall Buildings in Typhoon Prone Areas

The risk to tall buildings in the Asia-Pacific region due to typhoon events has been examined in detail country-by-country. CTBUH manages and implements the Skyscraper Center [7], the world’s largest database on tall buildings with entries on more than 13,000 buildings above 100 meters in height (and more than 25,000 tall buildings total).

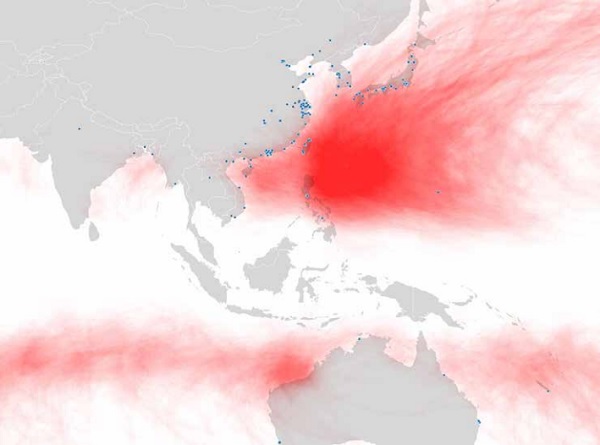

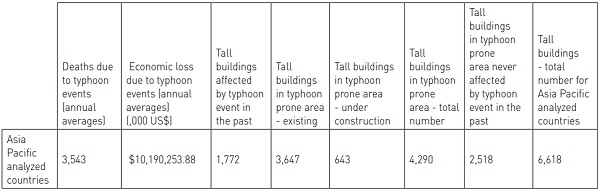

The geographic location of such buildings have been compared with the Geographic Information System (GIS) data of past typhoon events to identify how many tall buildings have suffered from typhoon events in the region (see Figure 1), and how many are located in an area that has been struck by a typhoon in the past and therefore is likely to be hit by extreme winds in the future.

Utilizing the GIS modeling of past typhoon events and tall building’s locations, the following information was extracted for the selected Asia-Pacific countries:

- amount of tall buildings affected by typhoon events in the past;

- amount of tall buildings in the same prone areas that could be affected now;

- amount of tall buildings in the same prone areas that could be affected in the near future.

1,772 buildings have experienced a typhoon, resulting in at least 16,500 total instances that buildings have been affected by 234 unique typhoon events in the past 45 years (336 of the 1,772 buildings have experienced a severe typhoon event with wind speeds greater than 150km/h).

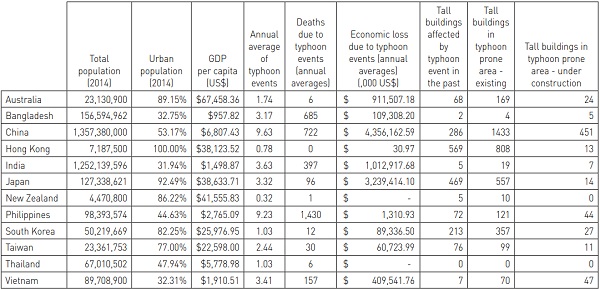

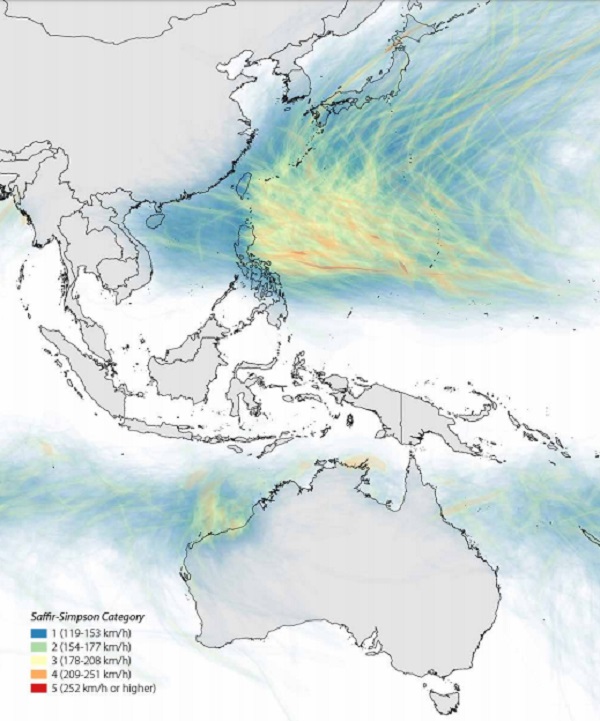

More than double the amount of buildings (3,647) are now built in these same areas that have experienced a typhoon event in the past (4,290 buildings are completed or currently under construction in these areas). This shows that the magnitude of the problem is increasing as a mix of increased number of tall buildings and severity of typhoon events. The list of countries analyzed in the research is shown in Table 1. It reports data about: local population; economy; effect of typhoon events; tall buildings in typhoon prone areas by each country [8] [9].

Data shows that there are no complete or under-construction tall buildings that are in areas that have experienced a typhoon event in the past 30 years in Thailand. That being said, the data analyzed by CTBUH does not take into account climate change, which is shown from the various parties as a principal contributor to these disaster increasing in frequency and severity. Thus, the buildings that are in these areas that have not experienced past events could very well experience a typhoon in the future. In this country the total amount of tall buildings currently complete or underconstruction is 165.

The summarized output of the GIS analysis for the Asia Pacific countries is displayed in Table 2. The total amount of Asia-Pacific tall buildings analyzed was 6,618 , and more than a half of those are located in typhoon-prone area (4,290).

Developed Countries Existing Codes and Standards Requirements for Typhoon Events Prone Façades

Australia (1975, following Cyclone Tracy) followed by the US (1994, following Hurricane Andrew) were the first developers of codes and standards requirements for typhoon prone regions.

In 1992, Hurricane Andrew hit the coast of Florida left 65 dead and $26 billion in damage to local buildings, especially to their envelopes.

In the following years, curtain wall provisions were added to Florida Building Code [10], which included the strengthening of building openings and glass surfaces to limit damage caused by high velocity windborne debris. This code represents the most demanding building codes in the US when it comes to impactresistance of façade systems from cyclone events.

The Florida Building Code regulates façades performance requirements with the Testing Application Standard [11] procedures (TAS 201-94, TAS 202-94, TAS 203-94 specified in the Florida Building Code). These standards provide the most stringent testing requirements on the research topic in the US. The Miami-Dade County best practice includes the product approval program with the Notice of Acceptance (NOA). These are set forth by Miami-Dade County for all construction trades and the Florida Product Approval organize the owner’s product acceptance [12].

In the ASCE 7-10 [13], the wind zone map is shown to identify the windborne debris regions and the boundary hurricane-prone regions. ASTM E1886 [14] and ASTM E1996 [15] requirements, or local standards requirements when more stringent, have to be follow by buildings constructed in US areas affected by hurricanes. ASTM standards dictate the glass composition for the building envelope, as well as, the air infiltration control during a disaster event [16] [17].

There are some differences between the wind zone map represented in ASCE 7-05 [18] and in ASCE 7-10. In ASCE 7-05 the wind speed is lower than in the ASCE 7-10. This reflected the definition of a safer wind speed map based on climate changes, but in the last edition of ASCE 7-16 wind speed maps represent reduced wind speeds for much of the country and clarify the special wind study zones, including new maps for Hawaii [19].

The International Code Council regulates areas in 130 mph wind zones and higher [20], which are identified as wind borne debris regions and in which it defines the required debris missile resistance. International Building Code’s references [21] are the ASTM E1886 and the ASTM E1996 standards.

The International Standard ISO 16932 [22] defines the destructive-windstorm resistant security glazing requirements and it has its references in the ASTM standards and in Australian technical requisites developed in the last decades, which are well rooted as best practices for the Asia-Pacific countries.

Asia-Pacific Countries Codes and Standards Requirements for Typhoon Events Prone Façades

Australia and New Zealand are the AsiaPacific’s most advanced countries in terms of the existence of codes and standards requirements for typhoon resilient façade design and construction. While test and performance requirements in Australia and New Zealand are well identified, they differ from the best practices in the US. The 2011 edition of AS/NZS 1170.2 ‘Wind Actions’ [23] included significant increases to speeds for the large missile (4 kg mass of timber) tests [24], which are now higher than those specified in the US.

However cyclic pressure testing following missile impact testing which has long been a requirement for roofing and façade panels in buildings in cyclone prone areas is not a requirement for typhoon glazing certification. The effect of cyclic pressures on the glazing construction component is well representative of the meteorological phenomenon of the typhoon event and has been identified in the US as a critical part of the testing protocol for missile impacted glazing. In other Asia-Pacific countries different kinds of approaches have been identified for building codes and standard minimum design requirements.

The straight input to refer at international or US standards for typhoon resistant glazing systems is given to Asia-Pacific codes users in some cases [25]. In some other cases foreign countries’ codes has been translated in local languages and locally adopted (i.e., the National Structural Code of the Philippines [26] is based on ASCE7-05 and is asking for the requirements specified in ASTM E1886 and ASTM E1996).

However there are circumstances in which these countries’ wind maps haven’t been updated in accordance with the increasing in the intensity of typhoon events due to last recorded disasters. There are Asia-Pacific countries without their own wind map although the standard authority translated and adopted a foreign code [27], but regional wind maps exist in region wide internationally recognized wind maps [28].

Many analyzed countries have been affected by typhoons every year in the past decades, but they still don’t have typhoon resilience construction safety requirements. If there are not specific codes for typhoon resistant façades it is commonly possible to use every more restrictive foreign code for wind, pressure cycling, debris resistance, in order to secure storm disaster façade resilience.

From the various parties consulted by CTBUH, it is evident that a major problem faced by contractors operating in the Asia Pacific region is that bids for new projects can be overexhaustive and contain a generic list of codes. It is up to the responsibility of the contractor to decide which one to comply with. Many foreign countries, the US, and international codes are frequently mentioned and, in most cases, no test requirements are needed for façade construction authorization process.

Typhoon Events Prone Façades – Generic Problems and Gaps in Standards

Façade resilience is needed to provide adequate safety during a typhoon event. This characteristic aims to primarily avoid broken glass. In Thailand requirements, from 1997 the glass in the external façade of high-rise buildings must be laminated safety glass [29].

This requirement is not directly related to typhoon resistance, but has an indisputable repercussion on environmental effects due to typhoon events. Australian Standard AS 1288-2006 Amendment 2 [30] in 2011 also recognizes the potential danger represented by the spontaneous breakage of toughened glass. Heat soaked toughened glass or laminated glass is required in buildings above a height of 5 meters. It is the only code to recognize the potential danger represented by spontaneous breakage of toughened glass.

The laminated glass composition used in typhoon resistant glass must resist both the design wind load and the missile impact specified by codes. The thickness of the glass lites in the laminated glass is determined by the wind load and the interlayer type. However, resistance to penetration by missile impact is determined by the interlayer type and the thickness of the interlayer. The interlayer thickness relates to missile impact speed, not to design wind load.

The purpose of ASTM E1886 and ASTM E1996 is related with the safeguard of human life and of public/private property. Building envelope failure caused by a typhoon event can have consequences on interior damage, internal pressurization, interruption of business during the renovation period, and can cause potential mold problems.

One of the gaps identified by this research, and confirmed by technical experts, is the need for improved testing of windows for wind driven rain over current international and US standard test methods. While the US standards for resistance to windborne debris and wind pressure cycling are adequate, the one area where improvement is needed is regarding wind driven rain. There are many standards related to this performance of the building envelope, but they are not required for cyclone prone region façades testing [31] [32] [33].

Conclusions

The purpose is to sensitize Asia-Pacific governments on security issues for typhoon resistant façades. If the local directives are not in line with the identified best practice, the most desirable result is that a maximum time is given by local authorities themselves to align these requirements to the most developed countries on the specific issue.

Skyscrapers concentrate in a small plant area, a large amount of inner surface and a huge amount of façade surface, compared to conventional constructions.

This building typology has always represented a symbol – for a company, for the society, a landmark in the city. This kind of construction has to follow the best practice for typhoon resistant glazing because in addition to interior damage, the potential effects to the external area due to storms is invaluable (glass breakage, internal objects downfall). For rapidly developing Asia Pacific countries, tall buildings best ambition is to have a new image in the collective function, serving as a refuge for local residents during disaster events [35] [36].

References

[1] World Bank Group, 2016b. “Reducing Vulnerabilities” East Asia and Pacific Economic Update (October 2016). World Bank, Washington, DC.

[2] Comes, M. et al., 2016. World Risk Report 2016. Edited by Bündnis Entwicklung Hilft (Alliance Development Works) and United Nations University – Institute for Environment and Human Security (UNU-EHS), 2016.

[3] United Nations Office for Disaster Risk Reduction www.unisdr.org/

[4] World Bank Group, 2017. “Sustaining Resilience” East Asia and Pacific Economic Update (April 2017). World Bank, Washington, DC.

[5] World Bank Group, 2016a. “Growing Challenges” East Asia and Pacific Economic Update (April 2016). World Bank, Washington, DC.

[6] Zhou, Y., Kijewski, T., and Kareem, A., 2002. Along-Wind Load Effects on Tall Buildings: Comparative Study of Major International Codes and Standards. Journal of Structural Engineering, pp. 788-796.

[7] The Skyscraper Center www.skyscrapercenter.com

[8] Global Risk Data Platform www.grid.unep.ch

[9] PreventionWeb www.preventionweb.net

[10] International Code Council, Florida Building Code – Buildings, 5th Edition, 2014.

[11] International Code Council, Florida Building Code – Test Protocols for High-Velocity Hurricane Zones, 5th Edition, 2014.

[12] Miami-Dade County, 2012. Notice Of Acceptance (NOA) General Submittal Information. Department of Regulatory and Economic Resources – Product Control Selection.

[13] American Society of Civil Engineers, ASCE/SEI 7-10, 2013. Minimum Design Loads for Buildings and Other Structures.

[14] ASTM E1886-13a, 2013. Standard Test Method for Performance of Exterior Windows, Curtain Walls and Storm Shutters Impacted by Missile(s) and Exposed to Cyclic Pressure Differentials.

[15] ASTM E1996-14a, 2014. Standard Specification for Performance of Exterior Windows, Curtain Walls and Storm Shutters Impacted by Windborne Debris in Hurricanes.

[16] ASTM E283-04, 2012. Standard Test Method for Determining Rate of Air Leakage Through Exterior Windows, Curtain Walls, and Doors Under Specified Pressure Differences Across the Specimen.

[17] ASTM E330-14, 2014. Standard Test Method for Structural Performance of Exterior Windows, Doors, Skylights and Curtain Walls by Uniform Static Air Pressure Difference.

[18] American Society of Civil Engineers, ASCE/SEI 7-05, 2006. Minimum Design Loads for Buildings and Other Structures.

[19] American Society of Civil Engineers www.asce.org

[20] International Code Council, ICC 600, 2014. Standard for Residential Construction in High-Wind Regions.

[21] International Code Council, International Building Code, 2015.

[22] ISO 16932, 2006. Glass in building - Destructivewindstorme-resistant security glazing - Test and classification.

[23] AS/NZS 1170.2-2011, 2016. Structural design actions - Part 2: Wind actions. Incorporating Amendments No. 1, 2, 3 and 4 to Australian/New Zealand Standard.

[24] Cyclone Testing Station, 2017. Technical Note No. 4 - Simulated Windborne Debris Impact Testing of Building Envelope Components (Version 4). Cyclone Testing Station, James Cook University, Australia.

[25] Bangladesh National Building Code, 2004.

[26] Association of Structural Engineers of the Philippines C101-10, 2010. NSCP National Structural Code of the Philippines.

[27] SNI 03-1727, 2013. Minimum load for the design of buildings and other structures. Standard National Indonesia.

[28] HB 212-2002, 2016. Design Wind Speeds for the Asia-Pacific Region. Australian Standards.

[29] Republic of Thailand, 1997. Law Regulation No. 48, Clauses 27-28, 1997. Minister of Interior. Issued Under Building Control Regulation 1979.

[30] AS 1288-2006, 2016. Glass in buildings - Selection and installation. Incorporating Amendment No. 2 of November 2011 to Australian/New Zealand Standard.

[31] ASTM E331-00, 2016. Standard Test Method for Water Penetration of Exterior Windows, Skylights, Doors, and Curtain Walls by Uniform Static Air Pressure Difference.

[32] ASTM E2268-04, 2016. Standard Test Method for Water Penetration of Exterior Windows, Skylights, and Doors by Rapid Pulsed Air Pressure Difference.

[33] AAMA 520-12, 2012. Voluntary Specification for Rating the Severe Wind-Driven Rain Resistance of Windows, Doors and Unit Skylights.

[34] Lieut. Commander Mark Moran, 2005 September 11. Location: Mississippi, Biloxi. Looking east down Beach Blvd (Hwy 90). Beau Rivage at right, Hard Rock Casino with trademark guitar visible at top center. NOAA’s National Weather Service (NWS) Collection, Image ID wea02506.

[35] Mori, H., 2015. Developing Tall Buildings and Urban Spaces, in Japan and Elsewhere. In: CTBUH Conference Proceeding of CTBUH 2015 New York Conference, pp. 122-131.

[36] Judah, I., Cousins, F., 2015. The Resilient Urban Skyscraper as Refuge. In: CTBUH Conference Proceeding of CTBUH 2015 New York Conference, pp. 230-237.

Acknowleddgments

The paper authors gratefully thank Kuraray Trosifol® World Of Interlayers, Phillip Davies, Richard Davis, Volker Gehl, David Chi and this research’s international peer reviewer team.