Date: 10 September 2008

The series consists of:

- MIRROR COMPACT with 4 brushes, 1300 and 1600-mm wide

- MIRROR ONE with 6 brushes, 1300 to 2200-mm width

- MIRROR TOP ONE with 6 brushes, 2000 to 3300-mm width

An air blade separates the (dirtier) water of pre-washing from that of the washing section, and rinse (normally by deionized water) can be recycled in the proper tank.

The quantity of cylindrical brushes can be increased depending on the different requirements, and special sections with circular tangential brushes, with alternate motion, can be installed for the previous scrubbing of the glass sheets, both on top and at the bottom.

All the machines lift up to 500 mm for maintenance and can wash 3 to 50-mm thicknesses. Each cylindrical brush has its own motorization, and steel rolls covered with vulcanized and rectified rubber are driven by bevel gear pairs: thus, no more belts or chains.

The stainless steel tanks, on wheels, can be easily pulled out from the wished side, and equipped, depending on requirements, with pumps, floats, mixer, heaters and temperature control systems.

Not only are all the parts in contact with water in stainless steel, but the outer protection crankcase are also MIRROR-LIKE stainless steel (hence the name of the series).

These washing machines have a totally automatic system and only work in the presence of the glass, thus considerably reducing consumptions and noise.

Besides, a whole series of further improvements is being tested and will be introduced at the forthcoming GLASSTEC show in Duesseldorf, to make more and more exclusive and effective the series of VITRODODI MIRROR horizontal washing machines.

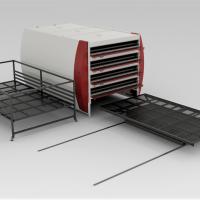

PULL-OUT a new generation of straight line edgers, born from a long experience in the field and from the solution of all the problems concerning maintenance and the complete accessibility to the whole machine.

PULL-OUT a new generation of straight line edgers, born from a long experience in the field and from the solution of all the problems concerning maintenance and the complete accessibility to the whole machine.

The main characteristics are:

1. Construction made of aluminium profiles which make it easy to be assembled, and of stainless steel crankcases which make it rust proof. Only shoulders and bed are in sturdy painted sheet.

2. All the machines are equipped with numerical control which automatically controls the adjustments of:

- glass thickness

- removal

- width of back arris

- width of front arris

- slope of mitering (on the variable angle model)

- heel (on the variable angle model)

- progress speed

In other words, we are talking of a completely automatic straight line machine.

3. Should you choose the model without numerical control, all of the adjustments listed above can be carried out manually by the operator.

4. All of machine movements (motor slides, opening of wheel drawer etc.) are on guides with ball recirculating pads.

5. Tool changing is made easy and quick by an innovatory and exclusive system representing a real revolution in the field: the whole spindle support (wheel drawer) is pulled out from the machine body through a pneumatic control, permitting the operator an easy handling on the machine front for all the operations of wheel change, dressing, or ordinary maintenance.

6. A whole series of functions, normally optional on the machines of competition, is on the contrary current on the PULL-OUT line, such as:

- inverter for glass progress speed

- separate stop of loading and unloading conveyor to load heavy glass sheets, while the machine continues working

- adjustment of loading conveyor to control glass removal

- extended loading and unloading conveyors

At present the PULL-OUT series includes:

- Edgers for flat edge with arrisses

- PRT 6 and PRT 6 CNC with 6 spindles

- PRT 8 and PRT 8 CNC with 8 spindles

- PRT 11 and PRT 11 C/CNC with 11 spindles with liquid cerium oxide

Edgers with variable angle - PAV 9 and PAV 9 C/CNC with 9 spindles with liquid cerium oxide

7. The maximum thickness is 31 mm, and the smallest piece can go down to 40 mm (to 85 mm on the variable angle ones).

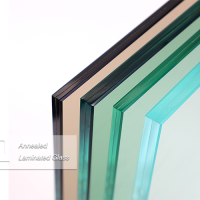

To produce laminated glass VITRODODI offer :  - STRATOVIT with monocomponent UV liquid resin.

- STRATOVIT with monocomponent UV liquid resin.

A simple and efficient system, more and more demanded for soundproofing, large sizes and special glasses (printed, wired etc.). The basic line consists of the STRATOVIT pump, the INCLIMATIC DOUBLE filling table, and the CIELO UV lamp oven and is available in the following standard dimensions: 2500 x 1600, 3600 x 2600 and 4000 x 2600 mm.

- with EVA without any autoclave.

For this production, VITRODODI offer the automatic coupling line for 2500 x 4500-mm sizes, complete with MODULO ONE washer.  - With PVB and autoclave.

- With PVB and autoclave.

In co-operation with GlassRobots we supply complete lines for laminated glasses sized 1600 x 3000,

2500 x 4500, and 3210 x 6000 mm.

Development can be in line, U or L-shaped.

The standard supply includes:

- loading table

- horizontal washing machine

- positioning station

- assembling station

- suction cup shuttle

- pre-pressing unit

- unloading table

- PVB-interlayer roll handling equipment, more or less automated

- Autoclave complete with compressors, accessories and glass-transport system

For more information, do not hesitate to contact Vitrododi on tel. +39-02-33501225, fax +39-02-3285617, e-mail info@vitrododi.com.

SFX Automatic seaming machine

This machine carries out the seaming in several shapes and sizes on glass sheets, in order to prevent them from breaking and assure a safer handling.

The machine has been designed so as to be inserted in other working lines or used alone upstream the double glazing processes and tempering furnaces.

Equipped with diamond wheels fitted on axles with recirculating ball guides, it grinds the glass by granting working.accuracy and speed.

A feeler at the infeed of the machine enables the machine to self-learn the glass size, and controls the wheel positioning so as to process arrisses of the same size.

Available in the following working heights: 1600 mm, 2000 mm, 2500 mm, 3000 mm

Speed 2-18 m/min.

Glass thickness 3-19 mm

Via Darwin 19,

Via Darwin 19,

20019 SETTIMO MILANESE (MI)

ITALIA

Tel. 0039-02-33501225

Fax 0039-02-3285617

e-mail: info@vitrododi.com

Add new comment