Date: 8 July 2025

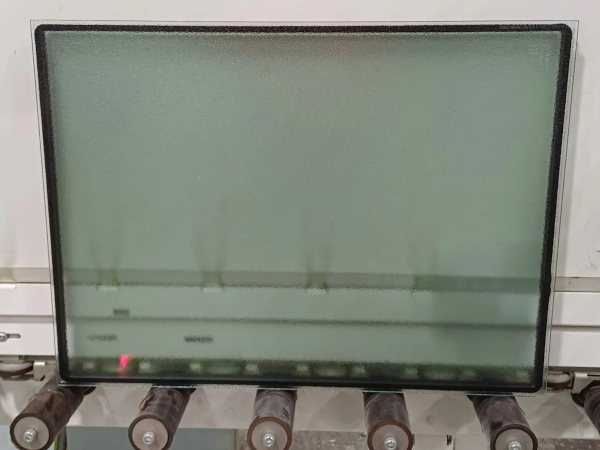

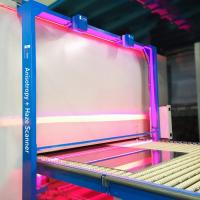

This next-generation inspection system features five independent detection channels that provide complete visibility into distortion, anisotropy, white haze, surface defects, and coating defects—delivering unmatched quality control for tempered glass.

At the heart of the system is True Edge™ Technology, which enables full-edge-to-edge scanning of the glass. This innovation ensures critical edge defects are detected reliably, especially important for downstream processes like lamination and IGU production, where edge quality is essential.

In today’s high-speed production environments, optical quality can suffer as furnaces are pushed to their limits. The Temper Scanner 5D allows operators to monitor and control distortion in real time—catching issues like pockets, hammers, sectoral rollerwaves, and edge kinks before they affect final quality.

Key benefits of the system include:

- Higher product quality

- Reduced customer complaints

- Improved process stability

- Greater customer satisfaction

This milestone marks a major step forward in Viprotron’s North American growth and a powerful example of what innovation and partnership can achieve. A big thank you to both the Trulite and Viprotron teams for their outstanding collaboration.

600450

600450

Add new comment