Date: 27 February 2018

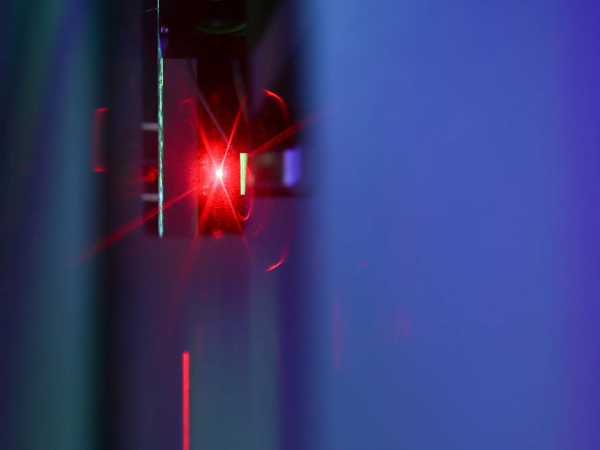

The LineScanner is a modular system for performing quality inspections on transparent flat glass products to check for optical and dimensional defects and distortions.

The scanner is easy to use and suitable for inspection of insulated glass units, automotive glass or processed glass. The flexible machine can be installed horizontally or vertically, quickly and easily and with minimal space requirements.

Especially in the glass industry, it's increasingly important, to meet the high demands of customers and partners. Since years Softsolution deals with the complex issue of checking the quality assessment of flat glass. Therefore we have developed a scanner which will revolutionize also your business!

Developed in Waidhofen/Ybbs, Softsolution produces unique LineScanners at the highest technical level. Many years of expertise and experience in the glass industry and with over 400 installations worldwide, Softsolution guarantees for excellent glass defect inspection systems on the market. Our LineScanner helps to deliver consistent quality to your customers and thus reduce the complaint ratios.

Features

- Capable of detecting overall dimensions, glass thickness, coated side, element structure, drill hole position and diameter, scratches, inclusions, fingerprints, coating voids, damage to edges, logo location and quality and screen printing position

- Suitable for use with float, coloured/printed, laminated, toughened and heat-treated glass

- Archiving software for quick and easy data capture and analysis

- Slim, modular construction is adjustable to customer requirements

Specifications

Maximum scanning speed: 48m/minute

Maximum glass thickness: 100mm

Maximum glass temperature: 70°C

Resolution: 200 or 400 dpi (400 dpi = 0.0635 mm)

Power supply: 230V, 16A, 50Hz, single phase

Operating system: Windows 7 or higher

See more at: www.glass-iq.com

600450

600450

Add new comment