Others also read

Thiele Glas enhances its quality control with the installation of the Temper Scanner by Viprotron.

Xinruineng ensures compliance with China’s 85% argon requirement by using Sparklike’s non-destructive gas measurement technology to guarantee reliable energy performance in insulating glass units.

Thomas Claude Sauer, Managing Director of EXXOSQEL and glasstec 2024 speaker, explains how a novel surface treatment “heals” micro-cracks at a molecular level — a breakthrough for lightweight design and glass industry decarbonization.

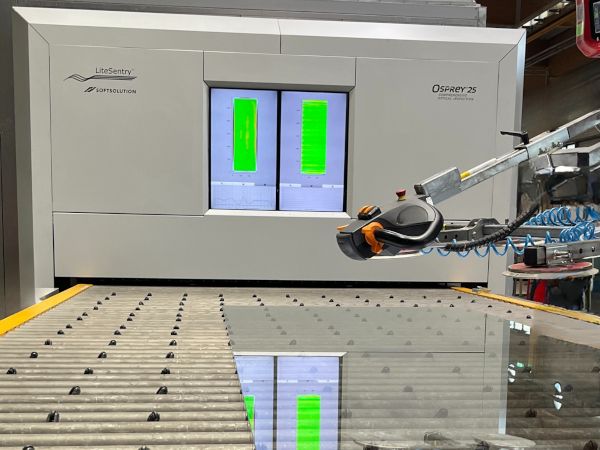

LiteSentry - Softsolution - Strainoptics will present their latest innovations in glass quality inspection at the 2026 Building Envelope Contractors (BEC) Conference.

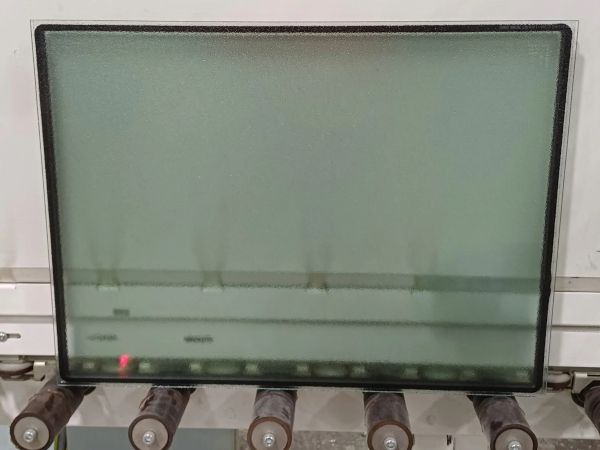

Project Scope: Inspection for All Types of Distortion, Anisotropy, Edge Stress, and Surface Quality.

New Group CEO brings 25 years of industrial automation leadership to global glassquality companies

Sparklike, a global leader in non-destructive gas measurement solutions for insulating glass units (IGUs), announced the appointment of Sasu Koivumäki to its Board of Directors.

A perfect-looking IGU can still fail. Explore why visual inspection alone is not enough to ensure real IGU performance.

This year marks the 10th anniversary of Sparklike Laser Portable™, a major milestone in the development of non-destructive gas measurement for insulating glass units.

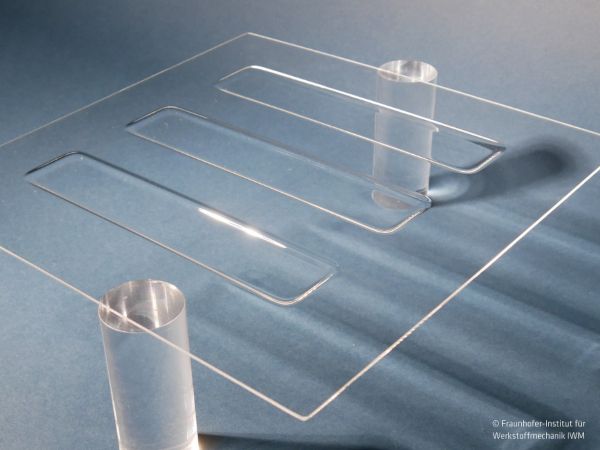

Tobias Rist of Fraunhofer IWM explains how an innovative laser process enables precise glass shaping, new structures and improved load-bearing performance for architecture and industry.

As customer expectations for energy efficiency and glazing performance continue to rise, SafeGuard Glazing Supplies has reinforced its commitment to quality with the Sparklike Laser Portable™ 2.2.

LiteSentry – Softsolution will participate in Eurasia Glass Fair 2025, held from November 15–18 at the TÜYAP Fair and Congress Center in Istanbul.

Sparklike Laser Integrated™ is a fully automated, non-destructive gas measurement system designed to be integrated directly into insulating glass (IG) production lines.

Sparklike continues to strengthen its global presence, connecting with industry professionals and showcasing its innovative gas measurement solutions for insulating glass (IGU) quality assurance.

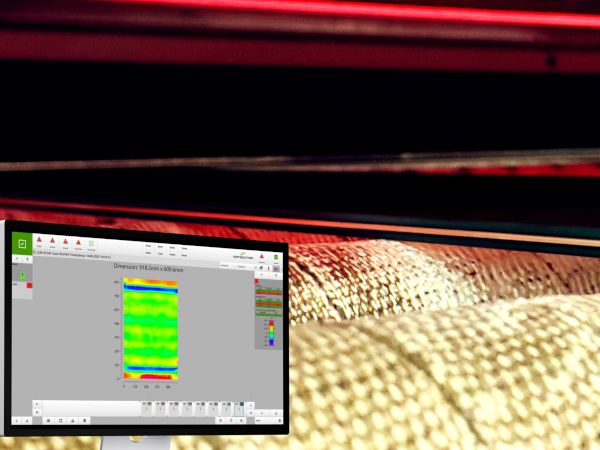

Automation and precision are redefining flat glass processing. In this expert article, Mika Eronen of Global Glass Specialists explains how dual-metric scanning is transforming quality control and boosting yield across the industry.

Visit Booth #9048 to meet the experts from LiteSentry, Softsolution, and Strainoptics and experience live demonstrations of cutting-edge inspection systems.

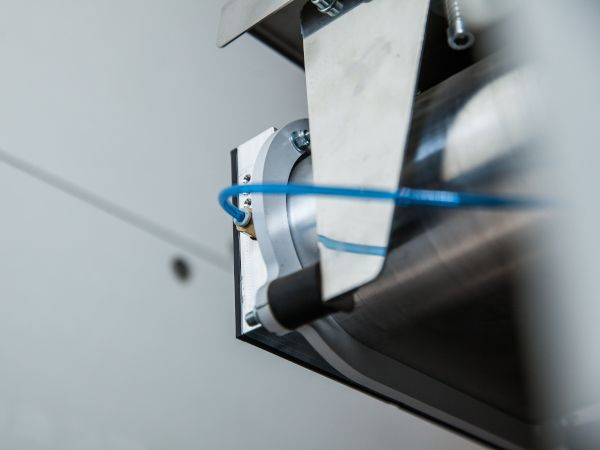

When perfection matters, even the slightest bow counts. The Bow Sensor keeps your production line running smoothly with real-time precision and total control.

Viprotron has unveiled its latest innovation — the Bow Sensor, a cutting-edge solution designed to detect and control glass deformations, or “bows,” early in the production process.

At GlassBuild America 2025, VIPROTRON will demonstrate how its latest inspection technologies are transforming industrial glass production — optimizing measurement, control, and quality across the entire production line.

From 24 to 27 March 2026, the world's leading trade fair will once again open its doors at the Exhibition Centre Nuremberg.

From the success of Vitrum 2025 to a full international trade fair calendar. Interview with Managing Director Matteo Padovan.

The quality and durability of insulating glass units (IGUs) rely on precise manufacturing processes, especially when it comes to gas fill levels and leakage rates.

FIT Show 2025 saw a record-breaking attendance of 10,129 visitors from 5,325 companies and hosted over 300 exhibitors.

Sparklike technology helps IGUs stay durable and energy-efficient by preventing gas leakage.

This autumn, Sparklike has been actively present at major international trade shows, reinforcing its commitment to innovation and global collaboration in the glass industry.