Date: 26 September 2025

Durability and energy efficiency are critical for insulating glass units (IGUs), used in modern buildings. However, exposure to environmental factors such as temperature fluctuations and UV radiation can degrade IGUs, leading to gas leakage and reduced thermal performance. A study by Asphaug, Jelle, Gullbrekken, and Uvsløkk (2016) on the accelerated aging of double-glazed sealed units highlights the urgent need for robust quality assessment tools to prevent energy losses and improve the lifespan of double panes.

Understanding the Challenges

The study explored the effects of accelerated aging on double glazed sealed units with different spacer systems. Over time, IGUs subjected to harsh environmental conditions, such as heating and UV exposure, exhibited significant reductions in argon gas concentration. This decline directly impacts the U-value, a key indicator of thermal performance, leading to increased heating demand in buildings.

Key findings include:

- Gas Loss in Spacers: IGUs with aluminum spacers showed an average 7% reduction in argon concentration, causing substantial thermal performance degradation.

- Impact on Energy Demand: Simulations revealed that reduced gas levels increased heating demand in buildings, significantly affecting long-term energy costs.

The Role of Sparklike Devices in Ensuring IGU Performance

Sparklike devices offer an effective and non-destructive method for measuring gas concentrations within IGUs. They all are suitable for double glazed sealed units, in addition Sparklike Laser devices to triple glazed. These tools are essential for monitoring and maintaining IGU quality, particularly considering the study’s findings.

Why Sparklike?

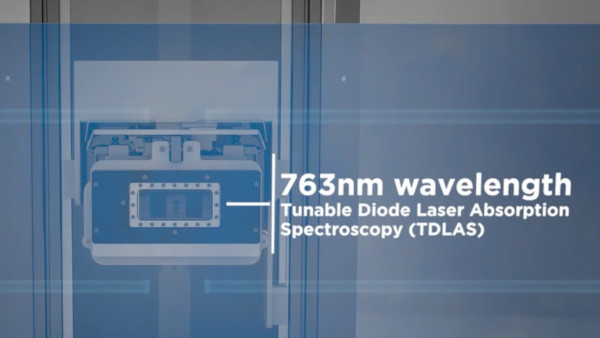

- Non-Invasive Testing: With Sparklike Handheld, you can quickly verify argon gas levels in double-glazed sealed units without damaging the glass. For both double and triple glazing, the Sparklike Laser Portable uses tunable diode laser absorption spectroscopy (TDLAS) to measure argon and krypton levels non-invasively.

- High Accuracy: Achieve reliable results under demanding production conditions with ±2% accuracy for standard IGUs. Backed by independent validation, including the ift Rosenheim test report, Sparklike gives you proof, not assumptions.

- Mobile and Versatile Devices: From the factory floor to the construction site, Sparklike devices give you full control of your quality verification. Eliminate the need for destructive laboratory sampling and take gas analysis directly into your own hands.

- Enhanced Durability Assessments: Detailed gas concentration data allows proactive maintenance and ensures the long-term performance of sealed units. Every faulty IGU prevented saves money, reduces waste, and supports sustainable building practices.

- Reputation and Compliance: Quality is not just about meeting technical standards; it is about protecting your brand. By proving gas fill levels, you ensure compliance with standards while reinforcing your reputation as a trusted, high-quality manufacturer.

Applications in Quality Control

The study demonstrated that IGUs with robust spacer systems and consistent gas levels maintain superior thermal performance over time. Incorporating Sparklike devices into manufacturing and maintenance processes ensures that IGUs meet high-quality standards.

Sparklike’s technology is particularly valuable in:

- Proving compliance with standards — demonstrate that your gas fill rates meet EN and ASTM requirements.

- Detecting issues early — prevent costly failures before units reach the customer.

- Verifying performance — ensure IGUs maintain insulation even in harsh environmental conditions.

Conclusion: A Proactive Approach to IGU Durability

As the building industry prioritizes energy efficiency and sustainability, maintaining the quality of IGUs is more important than ever. The Sparklike Laser Portable empowers manufacturers, installers, and quality control teams to detect and mitigate gas leakage issues of IGUs, ensuring reliable performance and reduced energy costs over time.

By integrating Sparklike devices into the IGU lifecycle, stakeholders can enhance product durability, optimize energy efficiency, and contribute to sustainable construction practices.

More information on Sparklike’s solutions and their applications in IGU quality control.

Contact Sales to Talk About Sparklike Solutions

Source:

Asphaug, S. K., Jelle, B. P., Gullbrekken, L., & Uvsløkk, S. (2016). Accelerated ageing and durability of double-glazed sealed insulating window panes and impact on heating demand in buildings. Energy and Buildings, 116, 395–402. https://doi.org/10.1016/j.enbuild.2016.01.015

600450

600450

Add new comment