Date: 31 October 2025

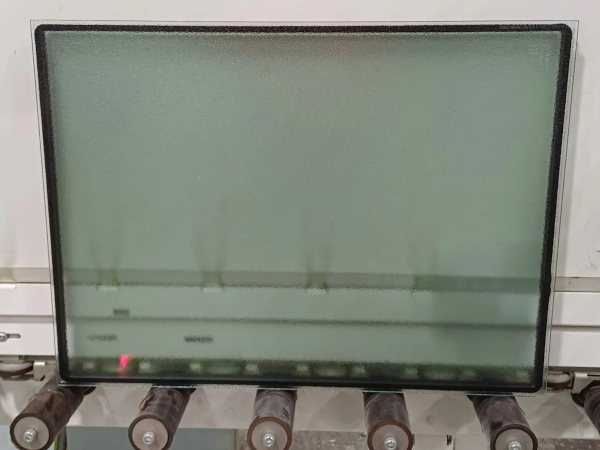

In modern glass manufacturing, precision is not optional but the foundation of efficiency and product quality. Even a slight bow in tempered glass can trigger costly disruptions: jams, breakage, scrap, rework, and delivery delays.

Our Bow Sensor brings transparency and control to a previously hidden risk, enabling real-time bow measurement during production without stopping the line.

Bow Sensor: Tackling the Hidden Production Threat of Bowed Glass

Bowed glass is often underestimated! Yet even minimal curvature can lead to serious manufacturing disruptions. When sheets leave tolerance, they impact production stability and downstream processes in multiple ways:

- Line jams and unexpected production stops

- Breakage and costly machine crashes

- Sorting interruptions and handling failures

- Rejection before IG or lamination

- Slower downstream processing steps

- Increased scrap and inconsistent product quality

Bowed glass is not just a cosmetic defect but represents a real operational and financial risk. A single warped pane can cause a chain reaction: wasted material, halted equipment, cleanup demands, and lost hours restarting the line. Identifying bow early ensures that one sheet never compromises an entire production run.

Bow Sensor Innovation: Real-Time Inline Bow Measurement Without Line Stops

The Bow Sensor identifies bowed sheets instantly before they create downtime or damage.

It delivers continuous, highly precise bow measurement up to 60 m/min, with no line stops or gaps required.

Key Performance Features:

- Real-time bow measurement

- Up to 60 m/min production speed

- Measurement range: up to 100 mm bow

- Accuracy: ±0.2 mm length

- Glass size: 300 – 3300 mm

- Horizontal or vertical installation

- Continuous flow – no stops, no gaps

- Stand-alone or add-on to Viprotron scanners

How The Bow Sensor Works: Dual-Track Precision

Accuracy matters especially at full speed. The Bow Sensor uses dual-sensor confirmation across multiple tracks:

- Paired sensors confirm bow on each transport track

- Multiple tracks provide global bow measurement across the full pane width

The result: high-resolution, reliable bow detection inline, at production speed.

Bow Sensor Benefits: Turning Risk Into Stable, Reliable Production

By identifying bowed glass early, the Bow Sensor prevents issues before they disrupt production. The result is a smoother, safer, and more efficient manufacturing process.

Key benefits include:

- Fewer unexpected production stops and crashes

- Stable sorting performance and reliable downstream processes

- Reduced scrap, rework, and material waste

- Higher throughput and consistent quality output

- Improved delivery reliability and planning accuracy

With real-time bow measurement built into the production flow, manufacturers gain predictable performance and avoid the costly chain reactions caused by warped glass.

Bow Sensor: Perfect Fit in a Complete Glass Inspection Ecosystem

The Bow Sensor integrates seamlessly into Viprotron’s inspection platform, complementing systems such as:

- True Edge™ – edge inspection

- Temper Scanner 5D – distortion, anisotropy, haze, coating & glass defects

Together, they form a full-spectrum quality control solution for tempering lines with the Bow Sensor closing the final major inspection gap.

Conclusion: Bow Control Creates Competitive Advantage

Bowed glass has long been a silent threat to productivity. The Bow Sensor transforms bow measurement into a controlled, measurable, and automated process parameter.

The result:

- More uptime

- Safe, predictable downstream processing

- Higher throughput and quality stability

- A smarter, more reliable production line

In short, the Bow Sensor converts potential chaos into consistent performance.

Ultimately, the Bow Sensor transforms uncertainty into controlled, consistent production – giving you the confidence to run at full speed without compromise.

600450

600450

Add new comment