Date: 6 November 2025

By Mika Eronen, Senior Glass Processing Expert at Global Glass Specialists

Automation Is Reshaping Flat Glass Processing

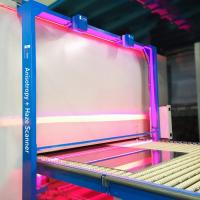

Automation and tempering precision are transforming glass processing, and scanner systems are becoming a vital part of this next leap.

In my work around the world, I see firsthand the cost of poor heat-treatment quality and the absence of automated testing. In today’s flat glass market, manufacturing cost and consistency determine survival.

At the plant floor level, processors still struggle to define what is acceptable in visual and geometrical quality for fully tempered (FT) and heat-strengthened (HS) glass. But it doesn’t end there.

Real Problems in Daily Production

1. Heat-Treated Laminated Glass

Even today, laminated glass processing remains a challenge.

Assembling during de-airing and autoclaving glass laminates often leads to trouble, especially when using nipper rollers or mechanical de-airing (“hot rollers”). These issues typically cause air penetration or even breakage in the autoclave. In the vacuum bag process, one usually achieves higher yields as the bag seals and protects the edges. However, it is vital to remember that potential issues bonded into the laminate surfaces remain there as manufacturing stresses, which, if extensive, will be released.

I’ve helped customers fix lamination challenges on-site countless times and heard the worst-case stories: glass breaking or delaminating after installation, well within warranty.

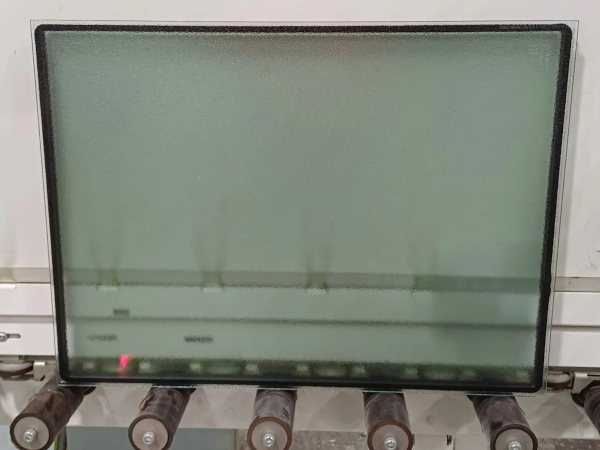

2. What the Eye Sees vs. What We Measure

Our eyes don’t measure in millimeters. We see distortion through reflected light and curvature.

The latest generation of quality scanners can measure in millidiopters (mD), a unit that directly relates to what the eye perceives. The automotive glass industry has used this measurement for decades. It’s a standard for OEM manufacturing, and I believe the same development is coming fast to thermally treated flat glass.

When we look at these two aspects (lamination performance and visible distortion) the conclusion is simple: It’s not only how flat the glass looks, but how flat it really is.

Dual metrics solve this effectively.

From Guesswork to Data

When developing a tempering recipe for new coated or special glass types, I often stand with the client’s team reviewing test panes under different lighting and shadowgraph conditions.

We all make our best “questimations” about whether the result will satisfy the end customer.

The same story repeats at furnace start-ups: what a furnace manufacturer’s technician calls “acceptable” tempering glass quality often isn’t good enough for an experienced operator or QC specialist. This is the know-how gap between experienced manufacturers and commissioning engineers, but it often reflects poor contractual agreements.

These differences in perception are expensive. With a scanner, optical quality turns from a subjective judgment into measurable data.

You can define your own in-house FT and HS quality specifications or even require performance values in millidiopters in your purchase contracts. That’s real, repeatable quality.

What Dual Metrics Actually Provide

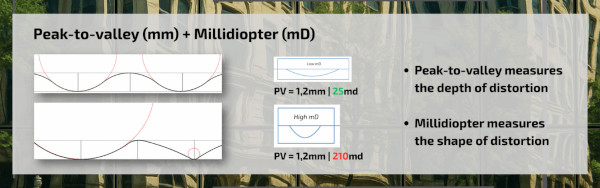

Dual-metric systems combine two complementary measurements that finally bridge perception of the human eye and repeatable precision in the most valuable way:

Peak-to-Valley (mm) + Total Surface Planarity

- Physical measurement of surface shape—roller wave, bow, edge lift, and even pitting.

- Shows the true shape of the glass pane after heat treatment.

Millidiopter (mD)

- Optical measurement of curvature and distortion visible to the human eye.

- Converts physical shape into visual impact: how the glass appears once installed.

Together, they tell the complete story of how the glass heat treatment was performed and how it will be seen.

What is the Impact on Lamination Efficiency

The planarity of tempered glass directly affects lamination.

Too much bow or edge lift during de-airing causes nesting problems, leading to air pockets and poor edge sealing, and therefore reduced autoclave yield.

Two main issues result:

1. Residual Air Dynamics

Excess air can dissolve into the PVB (or any interlayer) and later form bubbles, sometimes immediately visible, sometimes appearing during transport or years after installation when environmental conditions change. If edge defects are visible after autoclaving, those bubbles are typically located near the edge. A re-autoclave cycle may repair the issue, but part of your margin is already gone.

2. Edge Seal Integrity

Poor glass matching causes weak edge seals and “short vinyl” defects. Many try to fix this by clamping, but clamping is a non-value-adding bandage, not a cure for the root cause. It not only impacts manufacturing costs but also quality, adding stress due to localized interlayer thickness reduction at the clamp location – especially risky for overhead panes and heated or load-bearing units.

It is vital to understand that clamping is a bandage — and a costly one.

The clamping process is rarely standardized; pressure and distances vary between clamps along the laminate edges, often causing more harm than good. These variables degrade quality, essentially forcing two poorly matching panes together.

Depending on the application, this can lead to reflection optics issues, delamination during the warranty period, or even cracking once tensile stress finds the weak point — typically at the glass edge. If the unit faces changing loads from snow, ice, or heat, the risk rises even higher.

When I have planarity data from a scanner, I don’t need to prove manually that glass panes exceed the interlayer manufacturer’s edge-gap limits, which they often do. The data shows the story clearly: planarity is the root cause, not lamination. This shifts the focus from treating symptoms at the autoclave to fixing the source in the furnace.

Rather than explaining the long list of variables — rate of change, glass and interlayer thickness, float glass characteristics, edge treatment, and processing conditions — measurement data speaks for itself.

With it, processors can:

- Ensure proper lamination fits: FT and HS parts within optical and physical tolerances are effectively de-aired and meet all de-airing objectives.

- Boost autoclave yield: Fewer re-autoclaves (≤3%), less waste, and in many cases a complete elimination of “bandage-type” clamping or over-engineering with thicker, more expensive interlayers.

- Achieve stable production flow: Automated, inline feedback maintains tempering consistency and planarity — ensuring that both de-airing and autoclave performance remain within long-term quality targets.

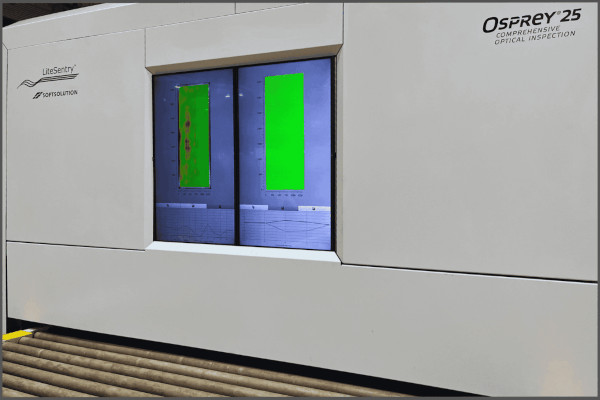

See how dual-metric inspection technology enhances tempering precision and redefines distortion and anisotropy measurement in the latest Osprey®25.

From Numbers to Understanding

The real power of these measurements is not only in the numbers—it’s in what they enable on the manufacturing level.

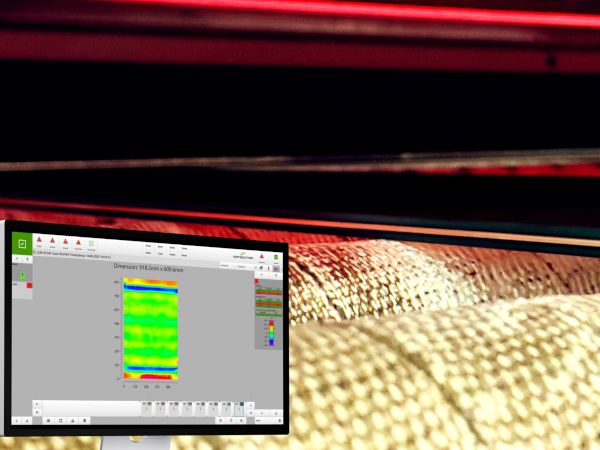

With millidiopter and peak-to-valley data feeding directly into the process control, operators can fine-tune furnace parameters instantly and see both the mechanical and visible results of each adjustment.

Dual-metric scanning brings precision to the intersection of human perception and process control.

It allows processors to guarantee that what looks perfect is perfect – both mechanically and optically.

When every pane is verified for both shape and appearance, the outcome is clear:

- Significantly higher lamination yield

- Reduced re-autoclave rates

- Less or no clamping during autoclaving

- Consistent, repeatable visual termpering quality

This is what data-driven, high-yield production looks like.

👉 Learn more at glassquality.com/osprey

A View from the Field

For me, these tools make on-site work easier—and sometimes, they make my role unnecessary.

Operators learn faster, recognize defects earlier, and solve problems independently.

That’s good progress.

My job is to advocate for what’s best for my clients, not what increases my workload.

Automation will continue to reshape flat-glass production, and scanner systems will remain a vital part of this next level.

I’ll continue to keep myself educated on what’s available to ensure my customers always get the best possible advice.

About the Author

Mika Eronen is a Senior Glass Processing Expert and founder of Global Glass Specialists, a consultancy supporting flat glass processors and vehicle glass manufacturers worldwide.

With over 25 years of hands-on experience in tempering, lamination, and process optimization across 50 countries, he helps manufacturers improve yield, stability, and product quality.

Mika’s insights come directly from the production floor, earned through thousands of audits, start-ups, and training sessions in glass plants around the globe.

🔗 Expert insights by Mika Eronen — discover more at Global Glass Specialists

Final Takeaway: By combining millidiopter and peak-to-valley data, dual-metric inspection brings tempering precision to every pane — ensuring consistent optical and dimensional quality.

600450

600450

Add new comment