Date: 27 April 2018

Integrated Automation Systems (IAS) is reducing pre-production lead times for its two-dozen customized glass handling and gas filling solutions from six weeks to two while also improving labor productivity and tracking and reducing shop errors.

Integrated Automation Systems (IAS) is reducing pre-production lead times for its two-dozen customized glass handling and gas filling solutions from six weeks to two while also improving labor productivity and tracking and reducing shop errors.

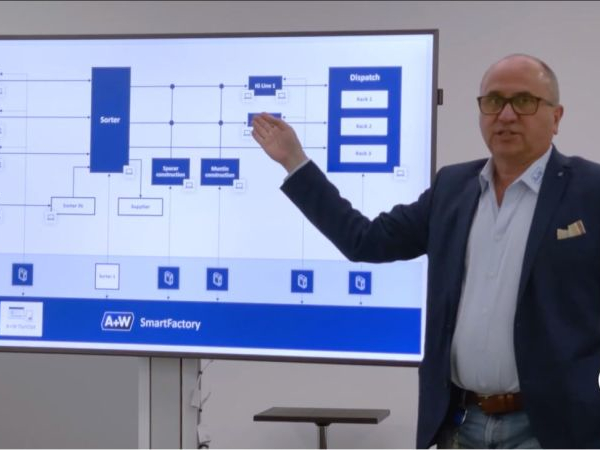

How? By moving bill of materials creation, purchasing and all operations from their accounting system to an ERP system built specifically for the demands of complex product and mass customization manufacturing.

“Our machines can have from hundreds to thousands of parts,” said General Manager Jim Collins. “Manually creating a SKU for each component to create purchase orders, which was the only way we could do this in our accounting system, took nearly six weeks. Our goal is less than two.”

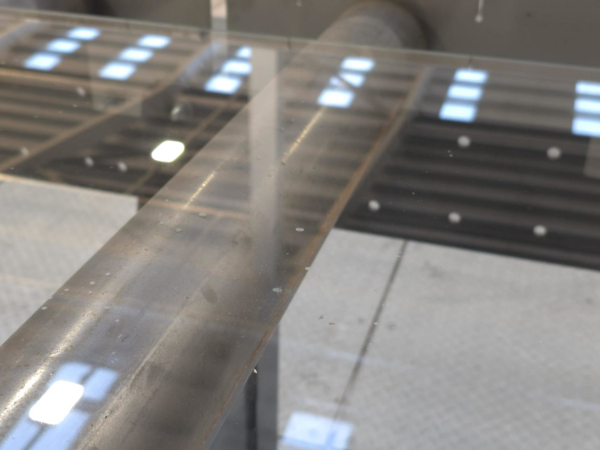

IAS (optigas.com) manufactures sophisticated dense storage and handling systems to manage raw glass, robotic and manual gas filling of insulating glass units along with quality control.

The company recently implemented Q2S ERP in their Bedford Heights, Ohio, facility to streamline their growing operation. The previous solution was unable to manage product deposits or oversee the 40-plus purchase orders common for a single job.

The key to reducing pre-production time is Q2S ERP’s dynamic and multi-level BOM configurator. With the rules-based configurator, IAS staff creates a product BOM by answering a set of pre-configured questions. The configurator database includes all parts needed for producing any possible system while only required assemblies are included for any item.

“The capabilities in Q2S are going to make a real difference in our bottom line,” says Vice-President of Sales Ryan McHugh. “We’re now going to be able to manage and mitigate the issues that occur with complex assembly of equipment where each solution is different.”

Separate SKUs are no longer needed for each option for a machine. Inventory is relieved on the final invoice and purchase orders automatically created. Maintenance is easier and purchasing and inventory are integrated with the dynamic BOM so that IAS will never run out of materials.

IAS is also looking to increase production efficiency, more easily on-board new employees, improve labor and production tracking and other improvements.

“The visual display at each work station makes it easier for our employees to see exactly what they are making, reducing errors,” says McHugh. “We will also for the first time be getting accurate hours and costs for each process and system.”

Q2S Director Ryan Anderson guided the Q2S ERP implementation team for IAS.

“IAS staff can now specify what is stock inventory and what is as-needed inventory,” she said. “Everything is visible to the purchasing department, so they can see what needs to be purchased for the specific job. And they can pro-actively follow-up on any past due PO’s before production even begins.”

Q2S ERP is a division of FeneTech, Inc, ERP software solution provider for manufacturers since 1996. Learn more about Q2S at q2serp.com.

600450

600450

Add new comment