Date: 23 October 2020

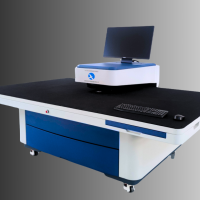

The Speed 25 is a three or four axis numerically controlled machining center designed and built specifically for fabrication of flat glass. This machine has a working envelope of 142” x 86” and can process glass up to 4” thick. The Speed 25 is available with an 18.5 HP (40 HP optional) electrospindle completely engineered and built by Cms. This machine offers a compact and ergonomic design by housing the water recycling tank underneath the machine and offering a waist high worktable for convenient loading and unloading via automatic (optional) sliding doors. The vacuum pump recycling tank also tucks neatly underneath the back side of the machine for an ultra-compact design.

This machine is very user friendly and versatile due to the large work area and easy to use control panel mounted to the front of the machine. The large touchscreen display adjusts up and down to accommodate operators of different heights. The water recycling tank is completely removable and fitted with wheels so maintenance and cleaning can be done away from the machine.

The Speed 25 is a much heavier build than the other machines in this class on the market. The accessories are neatly packaged in specific easy to access compartments making maintenance and service easy and worry free. The stiffness of the frame and accuracy of the dual direct drive servo motors combined with the high accuracy rack and pinion movement system and absolute encoders make this machine second to none.

600450

600450

Add new comment