Date: 17 July 2017

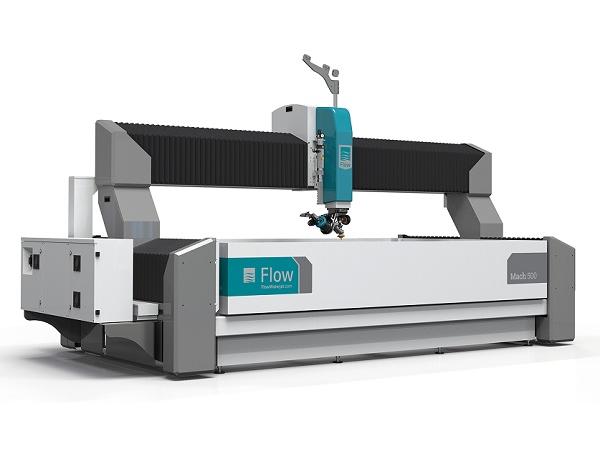

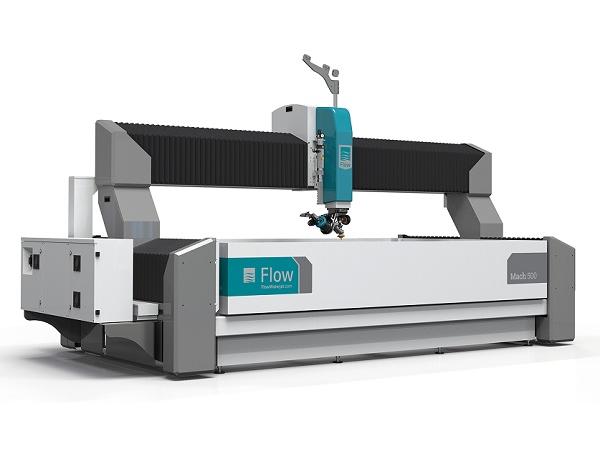

Flow International Corporation, the world's leading developer and manufacturer of ultrahigh-pressure waterjet machines for cutting applications, announced today the release of the Mach 500 in Europe, an entirely new waterjet system marking the arrival of a new industry standard.

The Mach 500 combines the latest in machine architecture and waterjet cutting technology with comprehensive service and support programs.

The main fields of use are machining metals such as aluminium, stainless steel, copper and brass, synthetic and natural stone and composite materials as well as cutting glass and plastics.

Together, the latest generation of FlowXpert® 3-D solid modelling CAD/CAM software and the recently introduced Compass™ 5-axis contour following and collision sensing solution enable the Mach 500 to make a quantum leap in terms of speed, precision and reliability, significantly boosting productivity.

Flow will present this system at ‘Schweißen+Schneiden’ trade fair, taking place at Düsseldorf from 25 to 29 September 2017 (hall 13, booth 13A59D).

With the Mach 500, Flow has successfully doubled acceleration versus previous models. This means a 15 to 30 percent reduction in cycle time relative to the Mach 3b, the company's best-selling waterjet cutting system worldwide.

The Mach 500’s Z travel height is 50 percent larger (305 mm) and repeatability (0.03 mm) has been doubled. The modern electrical system improves reliability of the overall system and reduces complexity.

The latest generation of FlowXpert® CAD/CAM software is capable not only of designing complete 3-D models and assemblies but also of simultaneously calculating optimum cutting paths.

"Over the last 40 years, we have developed 12 generations of waterjet cutting systems. With each generation, we have further improved major components and achieved ongoing increases in accuracy and cutting speed", explains Claus Herting, Managing Director, Flow Europe.

"The Mach 500 is not only a modern waterjet cutting system. It combines the latest technology from leading manufacturers of drive and control systems with Flow's tried and trusted ultrahigh-pressure technology and unparalleled service and support to maximize machine availability and productivity for our customers."

"The Mach 500 is unlike any other waterjet currently available in the industry,” says James Jenson, Flow President. “The system is quicker, producing more parts in less time than any other machine we’ve offered and is a major advancement for the waterjet industry. We have combined technology and service to give our customers a whole new level of overall quality, performance and throughput."

Thanks to the modular architecture and numerous configuration options, the Mach 500 can be individually tailored to customer requirements. For example, a range of pump technologies and cutting heads are available. All pump models are connected via EtherCAT to enhance diagnostics and upgradeability.

Compass™, the optional, patented multiaxial contour following system, has an integral collision sensor and enables precision cutting even on uneven surfaces.

Service and support packages can also be tailored to a customer's specific requirements. Options include preventive maintenance programs, replacement programs for high-pressure components, prompt delivery of replacement parts, technical assistance and a comprehensive training and development program.

Mach 500 is immediately available to customers in Europe and has made its début to the European market at LAMIERA, (www.lamiera.net) the sheet metal processing fair in Milan, Italy, in May 2017: https://www.youtube.com/watch?v=Tdw5oknMkNc.

About Flow International

Flow International Corporation, a Shape Technologies Group company, is a leading ultrahigh-pressure manufacturing process solution provider. As the world leader in waterjet technology, the company is committed to delivering highly innovative solutions and world class customer experience to a wide customer base.

Flow Europe GmbH, a subsidiary of Flow International Corporation, with a registered office in Weiterstadt, Germany and branch offices in England, France, Italy, Spain, Czech Republic and the United Arab Emirates, provides rapid technical assistance and ensures the smooth supply of replacement parts to all customers in Europe, the Middle East and Africa. For more information, visit www.FlowWaterjet.com.

600450

600450

Add new comment