Date: 10 October 2019

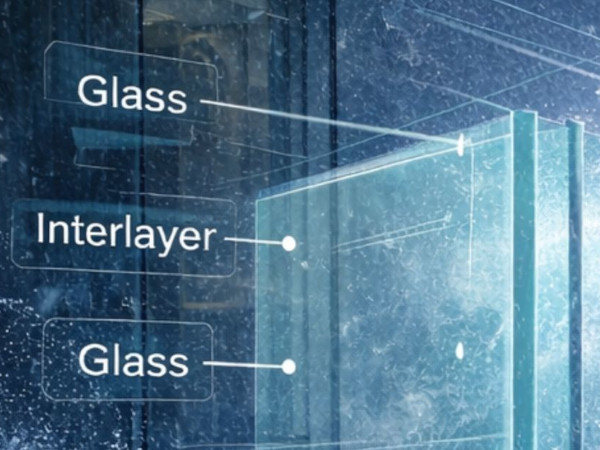

Windows, facades, gates and prefabricated wall and floor elements are becoming larger, heavier and more complex. At the same time, the demands on sound insulation are increasing, especially for high-quality properties and buildings in noisy areas. In addition, there are new requirements for sound test benches. Similarly, heavy rain, tornados and hailstorms must be considered as consequences of climate change.

For this reason, ift Rosenheim has decided to set up a new laboratory in Rosenheim on 1,440 m² for the testing of building acoustic properties as well as air permeability/ watertightness, wind load, impact resistance, earthquake resistance and alternating climate loads. The tests can be carried out according to DIN, EN and ISO standards as well as American and British standards. ift MessTec GmbH designs the laboratory and manufactures all test equipment.

Goldbeck is responsible for the planning and construction of the laboratory building. As a competent system construction specialist for turnkey commercial and industrial buildings, Goldbeck already completed the ift Technology Centre on schedule and on budget in 2016.

Building acoustics tests, expert opinions, research/standardization work and the development of testing technology have always been a cornerstone of ift Rosenheim. The competence, customer orientation and innovative spirit of ift-acoustic experts are therefore in demand throughout the construction industry. The same applies to the testing of facades, as many test methods for windows and curtain walls can be traced back to research carried out by ift Rosenheim under the direction of Prof. Seifert, Prof. Schmid and Prof. Sieberath.

On 9 October 2019, the ground-breaking ceremony for the new test laboratory “Building Acoustics + Facades” at ift Rosenheim took place. The start of laboratory operations is planned for the second half of 2020. A sophisticated logistics concept on an area of 1,440 m² (L 60 m, W 24 m, H 14 m) enables a fast and flexible reaction to customer requirements.

The immediate proximity to the already existing technology centre and the motorway simplifies the delivery of the test specimens as well as the coordination and monitoring of combined and comprehensive test concepts. During the planning phase, care was taken to ensure that tests are also possible in accordance with international standards (EN, CWCT, ASTM, etc.).

The ift Rosenheim is accredited for all these test procedures by the German Accreditation Body (DAkkS) and, together with its cooperation partner UL, can also provide the necessary evidence and certificates for the USA, Canada and the Arab region. With the new laboratory, ift Rosenheim meets the requirements of customers, standards and market needs. In addition, the coordination and testing by just one testing and certification body saves time and money, especially for international projects.

The new test equipment in the building acoustics laboratory combine large test openings with large room volumes (well over 100 m³) and therefore also meet the additional requirements of EN ISO 10140-2 for measurements in the low-frequency range as well as according to ASTM E 90.

The circumferential reinforced concrete construction of the flanking sound transmission test stand makes it possible to easily attach it to the upper floor and to decouple it from the rest of the building by floor, so that the project-related special features up to a size of 6 m x 4 m (W x H) can be optimally tested. A professional crane technology enables the simple handling of wall, floor and room elements weighing up to 16 tons.

Two test benches are planned for the facade laboratory, with which different test chambers up to a maximum width of 12 m and a maximum height of 12 m can be quickly adapted to various test specimen. A test stand is designed as a steel construction to meet the American test regulations.

This results in the best prerequisites for the reproduction of standard tests and special constructions for testing air permeability/ watertightness, pendulum impact (static/dynamic), impact resistance (from inside and outside), earthquake resistance in 3 axes as well as alternating climate loads (–18 °C to 82 °C) – also in combination.

This is supplemented by testing facilities in the Rosenheim main laboratory and in the new iftLAB Arnsberg (NRW).

600450

600450

Add new comment