Date: 28 February 2020

In cooperation with our British partner Promac we have realized another project abroad: “We are pleased that our long-time customer Starglaze from Great Britain has decided to use a LineScanner with latest scanning technology", explains Jonas Pfannenstill, Sales Manager at SOFTSOLUTION.

Starglaze was founded in 1974 and has been a family business for many years. Since its establishment, Starglaze has been manufacturing its own windows and doors and also offers a complete DIY store service for its customers throughout Lincolnshire, Nottinghamshire, Newark and the surrounding area.

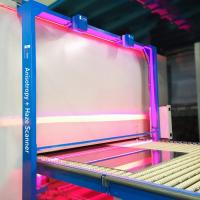

In order to meet the high standards of customers and partners, Starglaze was looking for a reliable, state-of-the-art glass quality inspection system. The solution: LineScanner, SOFTSOLUTION's all-in-one system that inspects glass lites with extreme precision for all quality and surface defects.

The vertical LineScanner with a height of 2,000 mm was installed on a Forel insulating glass line directly behind the washing machine and inspects the glass for surface defects such as inclusions or scratches. The LineScanner prevents faulty lites from entering the press where they are assembled into the finished insulating glass unit. The coating sensor, on the other hand, measures the thickness of the glass and ensures that the individual lites with the coating enter the press on the correct lite.

600450

600450

Add new comment