Date: 17 October 2018

In addition, a new generation of ARL-B45F filling systems has been designed to facilitate precise monitoring of target/actual desiccant quantity.

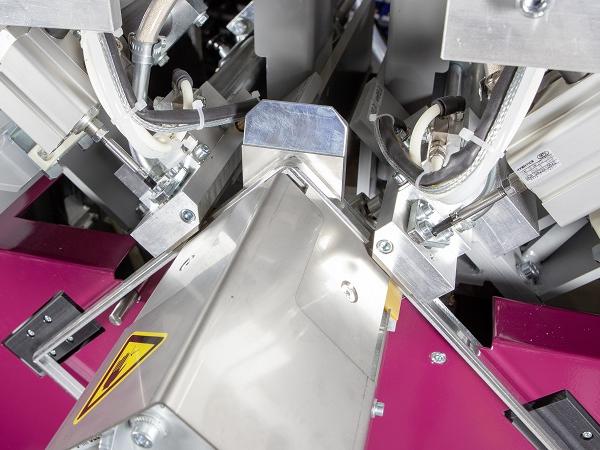

PERFECTLY FORMED 90° CORNERS WITH THE BSV-B45NK BENDING MACHINE

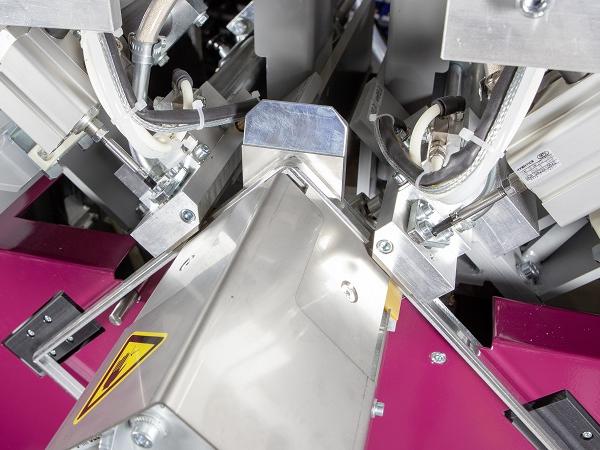

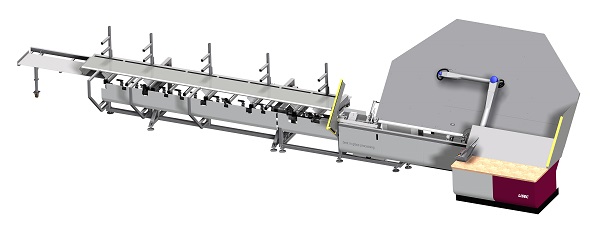

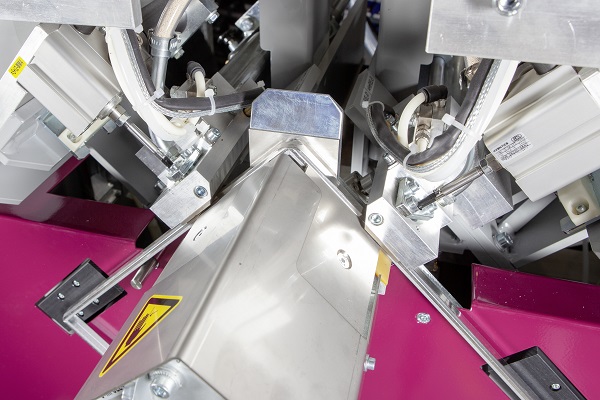

LiSEC has fully redesigned the established BSV-B45NK bending machine to accommodate the new developments in spacers materials. The previously used technology for spacer bending has been further refined, familiar spacers as well as new products can be bent in top quality.

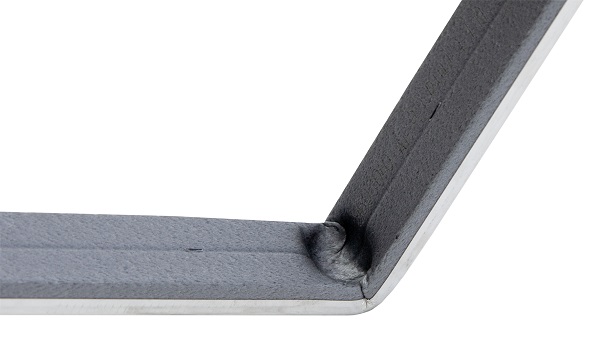

A new function of the bending machine is the integration of zero-radius corner (ZRC) technology. In addition to the familiar bent corners, spacers can now also be processed with this technology. LiSEC has successfully brought to serial maturity a newly patented process which allows tension-free, material-displacement manufacturing of 90 degree corners.

The highlight of the ZRC technology, which LiSEC has developed specially for fibre-reinforced spacers, is the self-stiffening corner. It produces a dimensionally stable and perfectly formed 90° angle. A further advantage of this technology is the maximised butyl application area in the corner.

HIGHLIGHTS:

- Zero-radius corner with fibreglass-reinforced plastic spacers

- Bending process supported by robotic arm

- Processing of aluminium, steel, stainless steel, hybrid and fibreglass-reinforced profiles

- Easy operation via touchscreen

OPTIONS:

- Shapes according to LiSEC shape catalogue

- 6, 8 or 15 slot profile magazine

- Control of ink jet printers

- Multiple labelling of frames

PRECISE CONTROL OF DESICCANT FILLING WITH THE ARL-B45F FILLING SYSTEM

LiSEC is setting a new standard with the semi-automatic desiccant filling station with ARL-B45F filling system. With this new generation of filling system, the design and the existing operational processes of the multi-functional device (drilling, filling and sealing process with butyl) have been optimised. The result is a reproducible and controllable filling process with shorter cycles. The target/actual quantity of desiccant filling is displayed to the operator on the screen and saved in a database at the same time.

Another highlight is the newly designed granulate flow process. With the help of flow-channel analysis interacting variables such as pressure, flow quantity and flow speed can now be optimized for the cross section of the profile. The sensor-controlled monitoring of the required desiccant quantity enables a minor deviation between the actual to target quantity. The geometric data of the profile can now be entered into the system via input screen on the display as well as via sensor-based spacer detection system.

Furthermore, the ARL-B45F stands out when it comes to composite spacers, because processing takes place on the rear side of the profile. The stepless height adjustment of the mono-filling head can also be adjusted to fit the respective frame dimensions.

Sebastian Payrleitner, product architect for insulating glass, explains the relevance of the actual and target quantity of desiccant: "Profiles with a traceable actual quantity of desiccant are a quality feature for insulating glass. If the actual quantity deviates from the target quantity in the profile, or if an already heavily saturated desiccant is used, the prevailing humidity in the chamber cannot be fully removed without leaving some residue. This phenomenon can be seen by as misting on the interior side of the glass in the insulating chamber."

HIGHLIGHTS:

- Desiccant quantity check

- Simple operation and universal application

- For aluminium, stainless steel, hybrid and plastic profiles

OPTIONS:

- Shapes according to LiSEC shape catalogue

- Filling of fibreglass reinforced profiles

600450

600450

Add new comment