Date: 7 December 2016

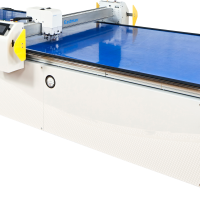

Energy Saving Glass has completed the purchase of a new Forel Laminate Vertical Cutting Line as the IGU manufacturer looks to expand glass processing business – including the supply of single sheet laminate and cut size laminate to the trade.

Alex Walker, Director, Energy Saving Glass, said that this gave the Kingswinford-based business, a unique platform, including the supply of single sheet laminate and cut size laminate to other IGU manufacturers and glass processors, in addition to its core trade business.

Alex Walker, Director, Energy Saving Glass

He said: “The addition of the Forel Vertical Cutting Line gives us a capability that none of our competitors have but also a capability that’s also out of reach to a lot of other glass processors and IGU manufacturers.

“We have invested in it, in part to fulfil the growing demand that we’re seeing within our own business for laminate glass but also demand from other glass processors.”

Capable of processing sheets of up to 6000mm x 3300mm the Forel Vertical Cutting Line achieves cut-to-size accuracy to within + - 0.2mm/linear meter, while the square cut is also guaranteed by revolutionary cutting bridges that adjust to within + – 15 mm to accommodate out-of-square glass.

Keeping glass in the vertical throughout the cutting process, also reduces tension of the applied load on the glass sheet and with it, the risk of breakage.

Walker continued: “This kind of collaboration isn’t necessarily how the industry has always done business but we see that as changing and as long as it works for us and for our customers, working with other glass processors, where it makes sense to do so, offers a lot of potential opportunity for everyone.”

Energy Saving Glass currently manufacture 4000 IGUs per week on a single shift, seeing dramatic growth in its customer base since moving into its new Kingswinford manufacturing facility in 2008.

The addition of the Forel Vertical Laminate Cutting Line is the third major purchase of Forel equipment by Energy Saving Glass. This includes two Forel IGU lines – both supplied by Promac - the most recent, a new triple-glazed line bought last year and 2 horizontal cutting tables along with other machinery.

The Promac Group also supplies PVC-U, aluminium and glass processing machinery from FOM Industries, BDM, Mappi, Pertici, Forel, Graf Synergy, Rapid, Pegic, Urban and MTL.

600450

600450

Add new comment