Date: 20 November 2019

Iiro has worked in sensor instrumentation and networks, R&D, industrial automation and quality management, and industrial business development. He graduated as M.Sc. (Tech.) in engineering physics (optical microsystems) in 2001 and D.Sc. (Tech.) in network technology (sensor systems) in 2012, both from Aalto University. The results of his doctoral thesis can be found in almost every mobile device (Bluetooth 4.0 or later). His blog is available here.

Iiro is a first person to hold the CTO position in Sparklike. Iiro’s responsibilities as a CTO are to cover all the tasks related to technical processes. Iiro will be planning and executing process updates like equipment production and internal/external quality assurance to mention a few key things.

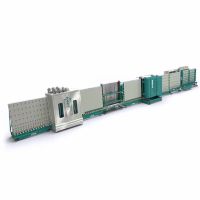

“Quality control is essential to industrial mass production. Integrating quality control to the insulating glass production lines is, thus, of prime importance to prove the customers that each product be compliant with the specifications. With Sparklike Online™, the insulating glass manufacturers get automatic quality control that meets the requirements of modern production automation." says Iiro.

600450

600450

Add new comment