All employees are extremely proud, especially the group leader in the mechanical assembly department, Heinz Burghard, who previously worked on the production of the first sealing robot.

The first sealing robot was developed and built by the former company Lenhardt Maschinenbau GmbH (now today, Bystronic Lenhardt GmbH), back in 1981. As the first pilot machine evolved, it was initially trialled for 9 months before being sold on to the first customer, Bischoff based in Bretten (Germany). Then the first customers had pre-arranged to evaluate this new machine for themselves. "Our long-standing customer Flachglas Wernberg (Germany) gave us the initial design suggestion for the shape of the nozzle", recalls Heinz Burghard.

Employees at Flachglas Wernberg proposed to the then managing director Karl Lenhardt, to develop a round nozzle rather than an immersion one. As it turned out, this was a decisive factor in significantly improving the quality of the sealing process. "The first worldwide sales of sealing robots subsequently followed" states Heinz Burghard.

The first sealing robot by Bystronic glass (Lenhardt Maschinenbau GmbH)

Revolution through evolution

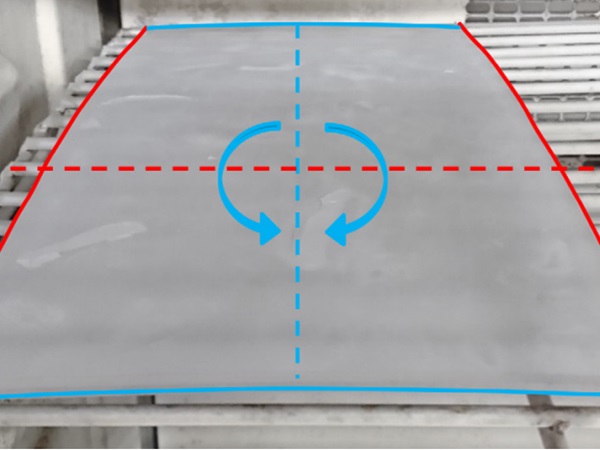

For Karl Lenhardt and his enthusiastic team, the prints on the glass caused by chain conveyors that were used at that time, were a thorn in their side. After numerous attempts to work with alternative conveying solutions the V-belt technology was introduced. Using this system, only the edges of the glass are positioned on the V-belt, therefore neither the glass surfaces nor the sealing material comes into contact with the belt. "At that time, I was dumbstruck at such a nonsensical design. However consequently, everybody grasped that this was the only way to achieve a perfect seal,” Heinz Burghard explains with a smile.

Heinz Burghard

Precise dosing technology

The following years saw many new developments and advancements, without which, today's Bystronic glass top model, the speed'sealer, would not have become the best sealing robot in the market.

In 1998, to save long waits between the dosing of the sealing material and insulating glass unit to be sealed, the gear pump dosing system was launched. Here, the dispensing equipment is attached directly to the sealing head, which results in an exact sealing material dosage.

"We always wanted to be a step ahead have adjusted the sealer accordingly to meet the needs of the market at all times", says Heinz Burghard. After the sealing robot was able to seal shaped insulating glass units, it was then presented at the glasstec tradeshow in 2000, equipped for the first time with conveyor belts for 4-sided stepped insulating glass units.

The market developed rapidly towards large glass facades and curtain walling, which were sealed with silicone. "We had to react quickly and developed a manual system for different sealing materials; however, this required greater input by the customer. The manual system therefore was soon replaced by an automatic material changing system", Heinz Burghard comments.

"Furthermore our customers demanded more in the form a faster mixing system. That is why Bystronic glass went on to develop a dynamic mixing system with a significantly higher flow rate compared to previously known static mixing systems, which ultimately seal I.G. units much faster".

Both systems were introduced for the first time at glasstec 2010 in the form of the speed'sealer.

Today's high-speed'sealer

The speed'sealer is a high-speed sealing robot. A triple insulating glass unit can be sealed in two rounds without the need for nozzle exchange or downtime. The speed'sealer is highly accurate and immediately adapts to changes in joint depth. Its self-monitoring system always ensures a constant mixing ratio of both material components.

"The speed'sealer is one great machine. I can hardly imagine any future direction for sealing robot development. We have implemented and achieved so much. I am very proud that I was part of this story from the outset and even today, I still work on the assembly of the speed'sealer ", concludes Heinz Burghard.

speed’sealer

About Bystronic glass

Bystronic glass symbolizes innovation with machinery, systems and services for the processing of architectural and automotive glass focused on tomorrow’s market. From basic requirements through to entire, customized installations Bystronic glass provides pioneering solutions – naturally, all in the highest quality. Bystronic glass is an international brand with globally operating companies that support their customers on site and through own sales and service companies. Since 1994, Bystronic glass is part of the Conzzeta AG, a renowned Swiss industrial holding company.

Bystronic glass media contact:

Julia Huber

PR / Online Communication

c/o Bystronic Lenhardt GmbH

Karl-Lenhardt-Str. 1-9

D-75242 Neuhausen-Hamberg

Phone +49 7234 601 120

Fax +49 7234 601 114

julia.huber@bystronic-glass.com

www.bystronic-glass.com

Bystronic glass sales contact:

E-Mail: sales@bystronic-glass.com

For the contact details of Bystronic glass global representatives please visit www.bystronic-glass.com