Date: 19 August 2025

A real game changer!

“Glaston Vortex Pro convection added to Glaston’s FC tempering furnace is making all the difference. With mixed loads and different sizes, this combo is a no-brainer. We would not be able to realize all the benefits without Vortex Pro’s extra functionality. I’m now wishing we had it on all our lines,” says Cory Brown, Director of Operations at United Plate Glass (UPG).

UPG, headquartered in Butler, Pennsylvania, with two additional locations in Lincoln, North Carolina, and Frederick, Maryland, serves the commercial and residential glass industry with architectural glass products.

“We have always aimed at achieving controlled growth and have been successful at doing that, with each location specializing in different products. We have deliberately grown at a steady and controlled pace to focus on quality. We have built our name by delivering quality products regardless of order size,” Brown says.

A lasting partnership with Glaston

In 1999, UPG purchased its first topof-the-line tempering furnace from Glaston. Currently, UPG has eight Glaston furnaces in production and has acquired ten Glaston lines over its 25 years of tempering glass.

In 2024, it was natural for UPG to go with Glaston again when they decided to replace an old furnace. “We have a very strong connection with Glaston – their premier products, the relationship, the service. With the mixed loads and types of products we produce, we wanted the best line on the market,” he says.

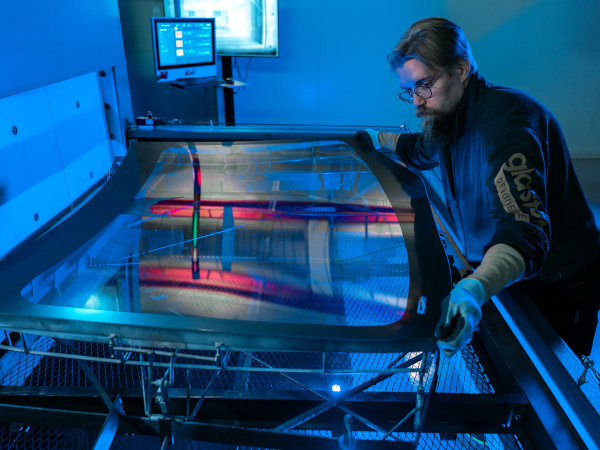

The newest Glaston FC Series X furnace with Vortex Pro has replaced the company’s 2011 line located at the Butler facility.

“It primarily handles a vast amount of our mixed, one-off orders for local glass shops or glazers who need a single replacement glass,” Brown says.

Vortex Pro adds more benefits

Brown was very familiar with Glaston’s FC Series furnaces – UPG has six of them. However, the Vortex Pro convection control system add-on was new to him. UPG first placed their order in May 2024 without the option. Meanwhile, Brown continued to do his research.

“The FC is the best furnace on the market to run high-performance glass,” he says. “I already knew that was the direction we were going to go. When I started familiarizing myself with Vortex Pro, however, I realized we could gain significant benefits by adding that option for the type of production we wanted to run on that furnace.”

They then ordered Vortex Pro while the furnace was still in production.

Smooth startup with expert guidance

Installation began in January 2025, and commissioning was completed by May 2025. Since all UPG’s FC furnaces are equipped with iControL, the company’s operators were already familiar with Glaston’s uniform and consistent interface, which made training on the new line easier.

“Training was very smooth. We focused on what was new and different with this furnace. Glaston’s Finnish engineer on site helped with his level of expertise, making sure all operators received hands-on learning while he stepped back to explain and advise,” Brown says.

After initial configuration, Vortex Pro works well on its own with minimal operator involvement. Now with multiple profiles created, Vortex Pro is just “set it and forget it,” Brown adds.

Load size increased by 21%

“This is the best equipment purchase we’ve ever made. We’ve increased our load size, our bed utilization, by 21% just by running mixed loads,” he says. “It’s fantastic!”

He goes on to say, “The quality coming off the furnace is unlike any I’ve ever seen before. In fact, I’ve had individuals insulating our product question if the glass was annealed. It was so flat – there was hardly any distortion.”

“In terms of production, the new furnace has been a real workhorse,” Brown continues. “From a quality standpoint, the FC-Vortex Pro combo produces a new standard of high quality. From a throughput point of view, the increased bed utilization makes much higher rates of production possible with mixed loads.”

UPG now has fewer running hours, making them considerably more efficient. They have decreased the number of beds, saving energy by not running as many cycles. “The furnace has been everything we expected it to be and more with absolutely no issues,” he states.

No longer making sacrifices

“Today, UPG is able to underline its slogan – quality, service and reliability. Earlier, we were running smaller loads because we never wanted to sacrifice quality. We would sacrifice efficiency and production instead,” Brown says. “Adding Glaston’s Vortex Pro option has now helped us achieve all three – quality, efficiency and throughput.”

UPG is now discussing more upgrades and is thankful to have invested capital in new, innovative technologies. “It is a huge benefit to have the ability to upgrade without having to scrap a piece of equipment that has a significant amount of life left in it. We can add new benefits to a functioning existing piece of equipment – and have seen the advantages of doing this,” he says.

600450

600450

Add new comment