Date: 11 April 2023

Effective protection glass meets three criteria and turns the invisible structure into an obstacle that is visible to birds. This was not always the case, as a closer look at the development process resulting in the current criteria and state of the art reveals.

The glass reflection is selectively broken up

People used to use a reflecting CD, a curtain or a black sticker in the shape of a bird to prevent birds from flying into a conservatory or a facade. Although these measures quickly lost their deterrent effect, the approaches to solving the problem meet two of the criteria of today’s protective functions: On the one hand, the birds are presented with an obstacle on the outside of the transparent surface and are able to detect that they cannot pass through it. On the other hand, the reflection is broken up by an object and the mirrored trees, bushes or sky lose their appeal. Dr Thomas Rainer, Authorised Signatory and Head of Development at the laser system provider HEGLA boraident, has been working on bird protection glass since 1995. As he wrote his doctorate on the subject of processing glass with lasers, the idea of realising a protective function via laser came naturally to him.

Protective pattern at position 1 makes approach unattractive

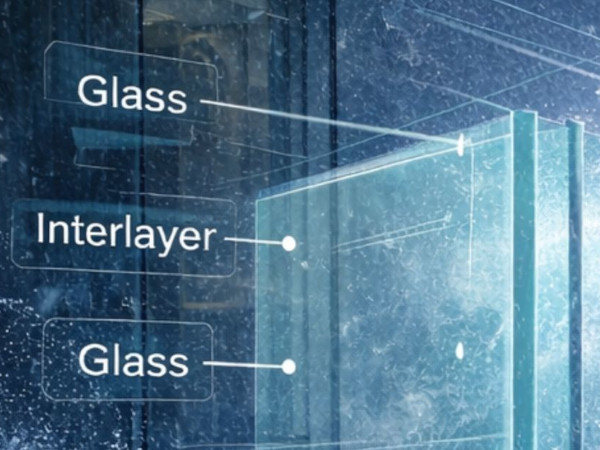

“The precision of lasers makes it possible to process glass without damaging the surface,” explained Thomas Rainer. “We wanted to leverage the properties of the pane by using the existing coating for bird protection glass.” The dot-shaped processing of the heat protection layers on the inside (position 2) creates a pattern that can be adapted to equal the wingspan of most types of songbirds. The birds recognise that it is impossible to fly through the pattern. Overall, this method achieved good protection. “In recent years, however, scientific understanding has advanced. Now we believe that the protective function should not be located in the gap between panes, but instead on the outside surface: position 1.” The reasons for this are based on the reflective properties of glass surfaces. Depending on the position of the sun and the reflected environment, the interplay of all factors can lead to the structure on the inside of the window becoming undetectable to birds and temporarily reducing the effectiveness of a bird protection structure at position 2. This is why the functional structures are applied to the outside surface (position 1) in the patented laser printing process of HEGLA boraident.

Scratch-proof, light-resistant and colourfast dots with modified reflection

Basically, the finishing treatment creates a balances among various interests. “In terms of architecture, glass is used to bring as much light as possible into the space and create the impression of openness to the surroundings. At the same time, this is dangerous for birds, because they cannot perceive the outside surface,” explained Thomas Rainer. This made the aim of balancing out these different interests with a transparent print even more important. The finishing treatment takes the form of semi-transparent dots with a diameter of between 5 and 9 mm at a distance of 50 to 100 mm to each other. To do justice to the special requirements of position 1, the dots are light- and weather-resistant, colourfast and scratch-proof.

If customers would like the print to be a visible design element instead, they can be opaque on a partial or full coverage basis. The two variants have two aspects in common: as the first protection criterion, the birds are shown that it is impossible to fly through the glass at position 1. As the second factor, the reflection of the glass is subtly broken up and adapted such that the bird’s eyes receive an additional warning signal.

Dispersion as an additional property

Functional laser printing also enables a third factor: it can modify light dispersion and provides protection in both the UV and visible light ranges. This also makes approaching the glass unattractive to birds.

Humans can barely perceive the dots or the pattern as they are semi-transparent, and their regularity makes them aesthetically appealing. “This made it even more important to us to scientifically document the effectiveness of our bird protection structure,” explained Thomas Rainer. This is why the laser system provider decided last year to have various glass qualities with different coatings and bird protection patterns tested by the American Bird Conservancy in the USA. The tested samples achieved Threat Factors of between 13 and 27. To be able to be classified as bird protection glass, a value of 30 or lower is required. In the USA, the test is required by law. In Germany, there are no related regulations. However, it is becoming ever more important for architects to document the sustainability of their buildings.

Bird protection structure on float glass, toughened glass, LSG and insulated glass units

With the laser process of HEGLA boraident, float glass, toughened glass and LSG panes and IGUs – be they individual pieces or a series – can be finished any production step. “The majority of our customers have their glass printed as the last step in the production process. This production step does not depend on the glass flow and is also possible later,” emphasised Dr Rainer.

The Laserbird laser system, which offers additional finishing treatments that include RF-transparent glass, is used for the process.

600450

600450

Add new comment