Date: 2 February 2022

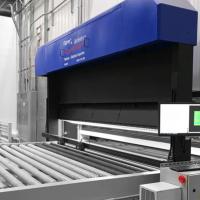

Each of these innovative SGG glass processing companies inspects the quality of the finished insulating glass elements using Softsolution's LineScanner. Working reliably 24/7, the system documents quality to ensure that only the highest quality ISO units leave the company. Read here to find out how this is put into practice at SGG.

With the Glass Thickness & Coating Sensor, the LineScanner is inspecting the entire insulating unit buildup including the individual lite thicknesses, the airspace, and which surfaces the coatings are located on. Strict quality criteria prevent any defective assembled units from leaving the facility. At the same time, the LineScanner stores the scan data such as sightline check results, muntin angularity, and other quality issues in a centralized data archive which can then be accessed in the future when analyzing customer complaints.

While the production line is running, the system displays the defects on the ISO unit with pinpoint accuracy. Some defects aren’t always visible to the naked eye and locating such defects on a large lite of glass would be comparable to trying to locate a grain of rice on a soccer field.

The LineScanner highlights these defects on the unit which prevents the bad glass from getting by while at the same time increasing the throughput by helping the operator perform his job quickly and reliably. Finding such defects earlier in the process prevents adding additional costs to an already defective unit. Reducing defective units leaving the facility, helps to cut back on transportation costs which is another way that the LineScanner also contributes to helping the climate by reducing transportation.

As Europe's largest glass manufacturer, as well as a Top Employer Global 2021 award winner and a global leader in coated glass, Saint-Gobain Building Glass Polska offers its customers high-quality glass products and supports all parties involved in construction and renovation projects. Whether comfort, efficiency, or safety are required, Saint-Gobain Polska can meet its customers' needs and focuses on four key factors: expertise, reliability, innovation, and passion. These are precisely the issues that have also been at the forefront of Softsolution for 20 years. The innovative hardware and software solutions of the LineScanner are used to provide stability, operational reliability, and performance to Softsolution customers around the world.

600450

600450

Add new comment