Date: 22 July 2025

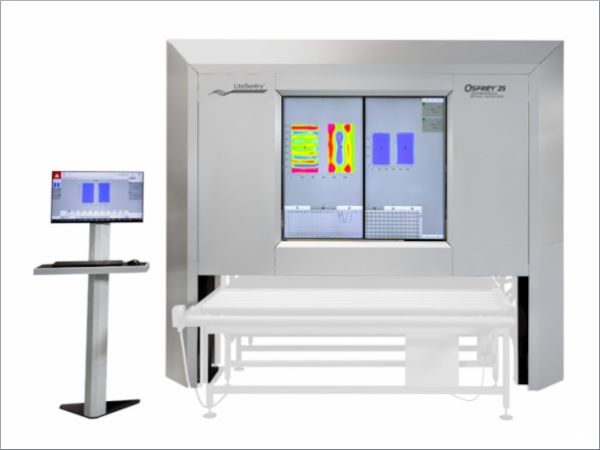

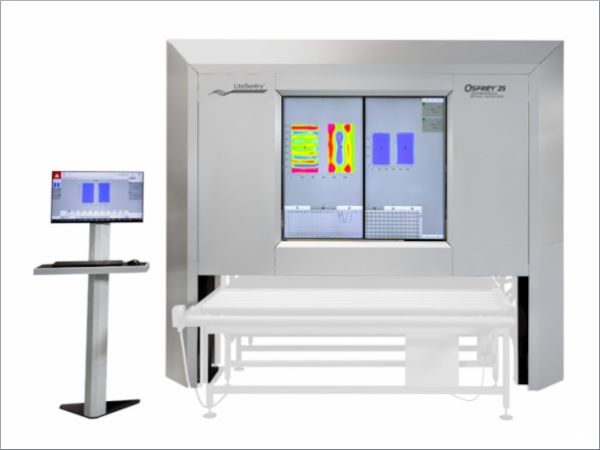

Recognized as the global leader in optical inspection for flat glass, Osprey®25 builds on its legacy as the gold standard for distortion and anisotropy measurement — and goes far beyond.

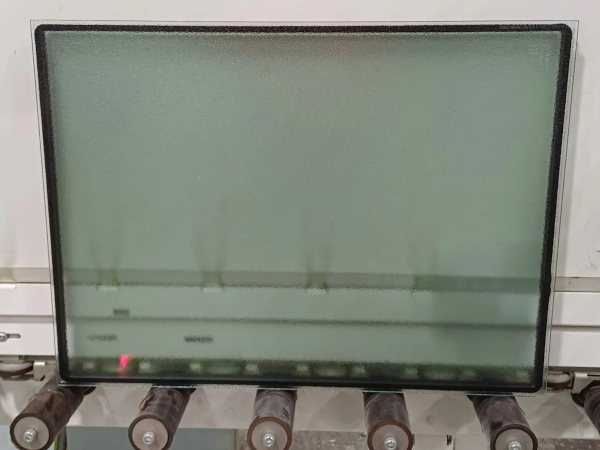

The latest version introduces comprehensive inspection capabilities, enabling the detection of surface defects, edge quality issues, and glass geometry — all within a single integrated scanning system.

From scratches, inclusions, and edge chips to logo placement and dimensional accuracy, Osprey®25 offers manufacturers a real-time, automated view of glass quality that sets new standards in precision and control.

“With the launch of Osprey®25, we're giving our customers a new level of control over glass quality — not just in distortion, but across surface, edge, and geometry as well,” says Peter PfannenstillVice President Sales & Marketing at Softsolution - LiteSentry.

“As the global leader in optical inspection, we’re excited to demonstrate what comprehensive, real-time quality assurance looks like — live at Vitrum.”

Live at the show: Smart Glass Inspection in Action

Visitors to booth J30 / J34 in Hall 11 will be able to see live demonstrations of the Osprey®25 inspecting flat glass for:

- Flatness and distortion

- Surface quality

- Edge integrity

- Geometrical accuracy

These live presentations highlight how Softsolution – LiteSentry continues to lead the industry in intelligent inline inspection, helping customers reduce waste, improve productivity, and ensure consistent, high-level quality.

All results are processed and displayed through a newly designed, fully customizable user interface and stored in a robust SQL-based quality archive. This enables operators and plant managers to identify, trace, and respond to quality issues more quickly than ever before.

Trusted by the World’s Leading Fabricators

With over 3.000 systems installed in 61 countries, Glassquality Family solutions are the choice of leading architectural, automotive, and technical glass manufacturers. The Osprey®25 continues this tradition by offering powerful integration into existing tempering lines, with real-time acceptance/reject logic, automatic alarms, and seamless compatibility with ERP environments.

Supporting Process Control and Profitability

In a manufacturing environment where time is precious and quality is paramount, the Osprey®25 provides the data and confidence needed to achieve flawless results—shift after shift. The system helps reduce rework, prevent complaints, and ensure compliance with the most demanding global standards.

About Softsolution | LiteSentry

LiteSentry is the original pioneer in flat glass optical distortion and anisotropy inspection and, along with Softsolution and Strainoptics, is part of the Glassquality Family. Glassquality companies develop intelligent, fully automated inspection solutions that help glass processors worldwide optimize production, reduce waste, and ensure high quality standards.

GLASS PERFECTION AT EVERY STAGE

Learn more at www.glassquality.com

Softsolution GmbH, Im Vogelsang 18, 3340 Waidhofen/Ybbs, AUSTRIA

Phone: +43 7442 539 88

Email: sales@softsolution.at

600450

600450

Add new comment