Date: 17 January 2019

With 32 employees and an annual turnover of about five million Euros, Dochy is, indeed, a typically small company. The company is located in West Flanders, Belgium and was founded in 1911. General Manager Vincent Blockeel took over the company in 2007 as no successor to the management could be found. Dochy processes single glass and laminated glasses for all types of applications and also produces mirrors.

Blockeel is straightforward and very clear in his thinking: “I know we are not a big size company, but we too have to deliver our products in the requested quality. In the past, I had no chance to invest in high-end equipment, which has become an absolute prerequisite to be successful and competitive. My visit to the glasstec show 2016 changed this.”

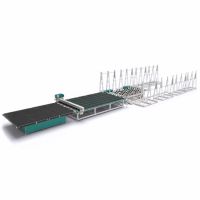

At that show LiSEC introduced their base series of products: solutions for glass processors that are located in so called emerging markets or for start up companies and newcomers to the industry. The base series of products offers LiSEC quality at an affordable price. And that is what counted for Blockeel. “With the previous cutting table we had problems all the time. It was only five years old, but when we dismantled it to make room for the base LAMICUT, there were dozens of screws lying underneath – this was not the quality I expected.”

Marcin Okwiek originates from Poland and operates the base LAMICUT at Dochy. Asked about his experiences with the LiSEC entry cutting table he can only find positive words: “I was a bit skeptical at the beginning, I admit, because I had never worked with a LiSEC machine before. Until I understood the philosophy of LiSEC and had worked a few shifts with the base LAMICUT. The design is far more industrial and fits the glass processing environment, it is very robust. Moreover, it is easier to make manual changes if necessary, which was impossible in the past.” Another aspect Marcin favors a lot is the safety of the cutting table. “The base LAMICUT is equipped with a well thought of safety system – now there is no risk any more of hurting myself”. Marcin also highlights the fact that cutting wheels do not break anymore. “In the past, cutting wheels broke regularly, which meant loss of time replacing them and also extra costs.”

Blockeel on his decision to buy a base LAMICUT: “In the past I would never have thought of buying from LiSEC – I thought it was out of range for me. Now they have the base series of products and address companies like mine. I think this is a clever move, now I can also afford LiSEC technology. And what’s more: I now work together directly with the machine builder, no dealer in between, that is a different business relationship.”

Blockeel plans to expand his company. “I intend to grow geographically and also to expand the product range.” Currently Dochy has its own profile system produced in China and intends to introduce this into the market soon. The General Manager is willing to invest in something new and build it up. “I would love to do that with LiSEC, since I appreciate their profound knowledge of the market and their skills to develop customer oriented solutions. I consider LiSEC a business partner one can trust.” To be continued …

600450

600450

Add new comment