Date: 24 January 2020

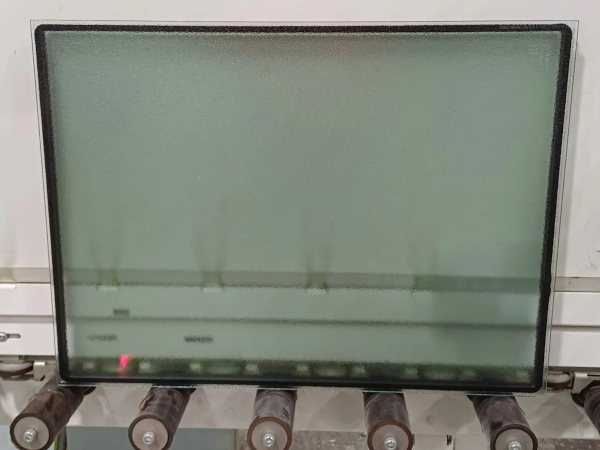

Products include both flat and bent tempered glass, as well as insulated glass, to meet demanding expectations of strength, thermal and aesthetic quality. As an innovative glass manufacturer, they are known for solving quality problems and on-time performance for both small and customer-specific orders and large production quantities.

One more reason to rely on an automated quality assurance system. The company has therefore been relying on a horizontal line scanner from SOFTSOLUTION since December 2019. The glasses are transported on a Benteler line through the washing machine and then checked by the LineScanner for dimension-, surface- and edge defects in order to meet the highest quality requirements on the market.

600450

600450

Add new comment