Date: 25 September 2019

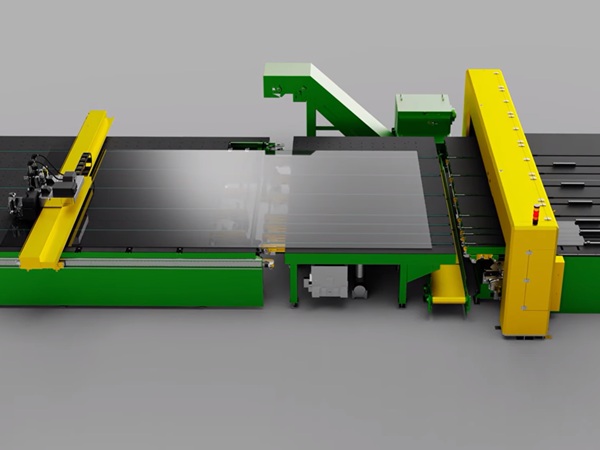

In 2019, the company will be investing in and expanding its London Docklands factory, which includes many new glass processing machines, a tempering oven and cutting tables.

Today, software systems and controls are an essential part of a state-of-the-art factory and must meet the requirements for optimally connecting old and new machines or plants in order to enable efficient planning and upgrade investments accordingly.

Software provides the interface that networks the machinery for this.

The LiSEC team was engaged to expand the existing LiSEC software system. The essential criteria for increasing efficiency included controlling production, establishing new connections to the new machines and monitoring the glass sheets in real time.

The LiSEC Software team was able to offer a solution that features the latest optimisations. This solution provides improved optimisation yields, detailed automatic links to other production sites and to LiSEC's central order entry system, so that orders can be processed automatically and efficiently between sites.

LISEC SOFTWARE IS ALSO COMPATIBLE WITH MACHINES AND PLANTS FROM OTHER BRANDS

A key advantage of the LiSEC software is its ability to link different machines from different manufacturers and simplify data transfer. This was also a decisive factor for Nicholls and Clarke in choosing software from LiSEC.

Barcode stations were planned and installed at key locations throughout the factory - not only to monitor products, but also to send essential information about each product to the relevant machine with 100% accuracy.

In addition, the Prodmon program, for example, features a search function that allows you to check the status of orders and articles in the factory, thus meeting one of the company's most important requirements.

In addition to these requirements, the software also performs other tasks in the background: Remakes can be scanned and recreated. A statistical analysis of these remakes is also possible in order to identify certain trends and processes for each machine.

A camera system for photographing and digitizing originals is used to create DXF files.

This allows the templates to be included in the optimisation and the shapes to be bundled. As a result, there is less glass waste. The DXF files can also be sent to the appropriate processing machines by reading a barcode, which significantly increases the overall production speed and precision.

In addition, the camera system provides a photo and a DXF file for each template, which makes it easy to store and recreate templates based on previous examples.

Richard Howe, director of Nicholls and Clarke, is very pleased: "LiSEC Software has been our software provider for many years. Of course, that's why we approached them so that they could provide us with a solution tailored to our needs. We are more than satisfied with the result."

Ged Smith of LiSEC Software UK commented on this project: "LiSEC Software has set a trend in the glass industry for ensuring greater control over glass sheets and processes. Better control means more efficiency, fewer errors, less costs, more satisfied customers and more profit. The market is very competitive and margins are increasingly shrinking. It will probably also be more difficult to recruit a low-cost workforce in the future. This is why investments should be made in high-quality software that has the breadth, depth and corresponding structure in terms of support. Efficient control and a constant flow of information will yield increasingly more advantages for future-oriented companies."

600450

600450

Add new comment