Date: 9 December 2025

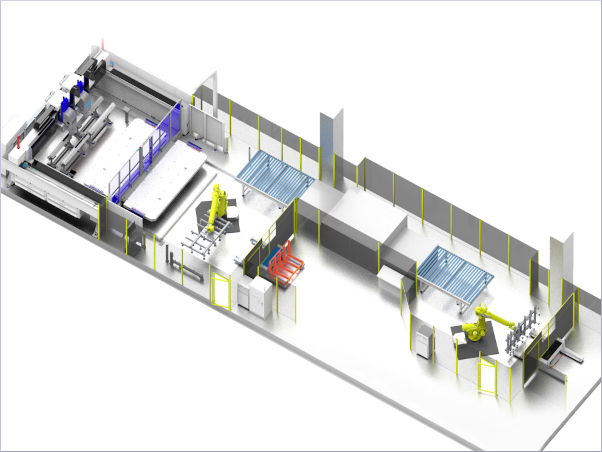

Grupo Tecnovidrio has taken a decisive step forward in its growth with the launch of a new production plant in Toluca, Mexico. Equipped with TUROMAS technology, the project incorporates two RUBI 517C float glass cutting tables and an automatic glass storage system.

With a family history dating back to the early 20th century, Grupo Tecnovidrio continues a long-standing glassmaking tradition in Mexico. Founded in 1992 by José Antonio Riestra, the company builds on the legacy started by his grandfather—one of the country’s pioneers in mirror manufacturing—and continued by his father.

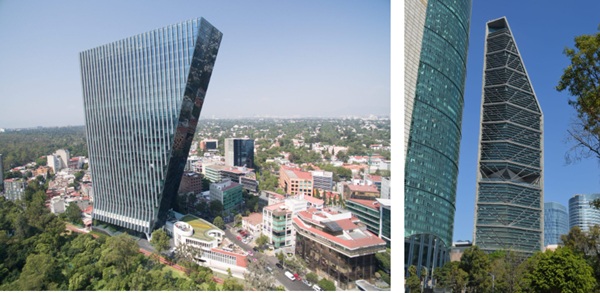

Today, the company continues to evolve, combining craftsmanship with advanced technology to offer large-format glass solutions, laminates and low-emissivity glass for high-end architectural projects.

“We focus mainly on architecture and on special projects involving large-scale glass installations. Our goal is to make the dreams of those who design them come true,” says José Antonio Riestra, Managing Director of Grupo Tecnovidrio.

Throughout its history, Grupo Tecnovidrio has taken part in some of Mexico’s most notable projects, such as Torre Virreyes, Torre Reforma and the Los Cabos Convention Centre, where the challenge was to deliver large glass panels within a very short timeframe for the G20 meeting.

The partnership with TUROMAS: technology supporting planning and efficiency

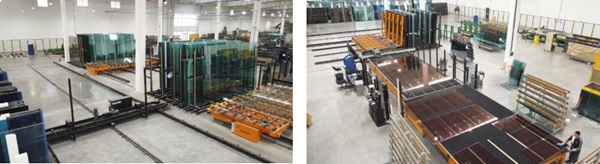

In its latest expansion phase, Grupo Tecnovidrio entrusted TUROMAS with equipping its new plant with state-of-the-art machinery for automatic glass cutting and storage.

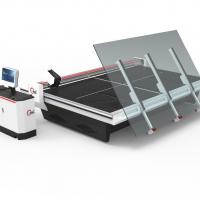

Technical solution provided

From the outset, the technical teams at TUROMAS and Tecnovidrio worked together to design a solution that would meet both current needs and future goals. The result is a phased project that facilitates technological adaptation, staff training and the transition to a more automated and efficient workflow.

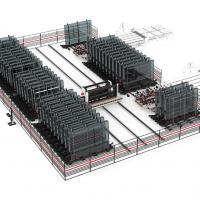

To feed the cutting lines, an SR-07 rack shuttle smart warehouse with 39 positions and a storage capacity of up to 624 tonnes of glass has been installed, including an external reloading position that allows the system to be supplied without interrupting the loading cycle.

Both the cutting lines and the warehouse are designed to work with two standard sheets or one jumbo sheet, increasing versatility and optimising daily operations.

The next phase of the project involves adding two scrap warehouses, one for each cutting line, completing the full integration of the storage and material utilisation system.

“The TUROMAS team was fully involved. They understood our needs and provided great support throughout what was not an easy project. The TUROMAS team is truly on par with any manufacturer in the world, offering equipment that is easy to use yet based on cutting-edge technology.”

True to its family philosophy, Grupo Tecnovidrio fosters close, trusting relationships with both its employees and suppliers.

“What we aim to do is grow together. This project has been a big step for us and an example of what can be achieved by working as a team,” concludes José Antonio Riestra.

The collaboration between TUROMAS and Grupo Tecnovidrio is an inspiring example of how the combination of experience, innovation and trust can transform a vision into a productive reality. With cutting-edge technology and close cooperation between teams, Tecnovidrio’s new plant has become one of the most advanced in the sector in Mexico, ready to face market challenges with efficiency, precision and flexibility.

600450

600450

Add new comment