Date: 12 April 2011

Not only has the Hegla system contributed to increased warehousing efficiency but it has also enabled the company to maximize upon the potential of the new facilities and to expand manufacturing capabilities with an eye on tomorrow’s market.

Enhancing the storage capacity and efficiency in brand new premises however, were not the only criterion for the Hegla team to consider when designing the system. Window Widgets new facilities had been specifically chosen because of its close location to the motorway network whilst also having recently benefited from a £1.5 million refurbishment by the previous owners which suited their needs perfectly.

The actual floor space of the new premises however would not allow the comprehensive selection of profile to be stored with conventional cantilever systems. A different solution was required as the alternative option was to move into an adjacent unit which had a much larger floor space but at a vastly increased cost.

Whilst Hegla is well recognized for its expertise in glass handling and storage, the company is equally proficient in providing solutions for the profile market and even uses these types of racking systems within its own production facilities for exactly the same space saving reasons.

For this project it was essential that the Hegla racking and storage system could not only accommodate fast moving stock but that it could be tailored to fit exactly into a designated area inside the building.

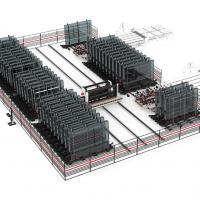

The Helga design team specified a solution for Window Widgets that would accommodate the storage problem within the space limits given, in the form of a large, semi automatic floor to ceiling concertina racking system for bulk stillage quantities, along with a smaller manual concertina system for pack quantities or individual lengths of profile.

Unlike cantilever systems that are fixed to the floor with working gaps between each section for fork lifts to operate, the Hegla system offers major advantages with the need for only one gap along the whole run, which appealed to senior management at Window Widgets.

The system allows the operator to select a position where profile is stored and then that gap is opened to allow the fork lift to enter. The operator can then close this gap and open another section for his next stock selection. All this is done via a motorized coupling bogie system on which the racks sit. There is a safety light beam system which protects workers within the system as well as an audible warning system informing that the racks are moving.

Since the installation of two Hegla racking systems, which were manufactured in the corporate colours of Window Widgets, the company has seen further growth with Hegla’s system proving highly versatile enabling the proliferation and storage of increased stock

The space saving benefits of the Hegla system were crucial on this installation as it was essential to accommodate the product from three separate units into one very specific, larger facility. Subsequently, the racking systems have more than doubled the storage capacity whilst at the same time have increased the production floor area substantially.

As a direct result, the company has been able to take full advantage of this extremely effective concept from Hegla by making substantial investments in other business areas. The cost saving benefits have consequently enabled Window Widgets to adapt the 21,000 sq.ft floorspace to accommodate 13 injection moulding machines, an extruder as well as a CNC lathe and saw to allow for in-house manufacturing and complete control of stock from under one roof.

Hegla’s installation not only meets the existing storage requirements of the company but, importantly, provides additional capacity for growth in the future. Based on its continuing success story in the window industry, Window Widgets has established a formidable reputation with niche products and services which are recognized throughout the industry for their excellence.

Dan Gill, Managing Director at Window Widgets comments: “We produce a comprehensive range of products for the window industry that is continually growing. The glazing sector is highly competitive so we have to ensure that we can produce and store high volumes to ensure we meet our customers’ expectations. One of the key benefits to the Hegla racking solution was that it was tailormade to our exact requirements and it was essential that it could be quickly installed into our new premises so that we could maintain efficient customer services.

He continues: “When a company has to expand, particularly during difficult economic times, investing wisely is imperative and we consider this system is ideal as it has saved us so much money. Everything is more compact and it is more efficient because of the height. As any business owner will agree when looking at new premises or even existing ones, height costs nothing so again the Hegla system offered huge advantages.”

Having achieved the Glassex Award for Innovation last year the company has been acknowledged and rewarded for its forward thinking approach to design and development. As the range complies to the stringent industry manufacturing standards the company is recognized for its quality. Today, after steady but substantial growth, Window Widgets intends to further streamline production to allow for further product diversification and future investment in Hegla storage systems.

With a comprehensive yet growing collection of products it is almost impossible to fully grasp the entire extent and benefits of the Window Widgets range, which have been meticulously developed over the last 10 years. It was imperative when making the investment that the Hegla system would last and could accommodate the considerable product development that was/is planned.

Hegla’s reputation for quality and superior standards was well known to Dan Gill, who has great vision for the future. As Window Widgets moves to develop more mainstream products and expands its portfolio to include products such as the ringbeam for conservatory door spans, he considers he can rely on the Hegla racking system to accommodate the company’s growth.

Dan Gill concludes, “Our brand and company is recognised and respected for its quality and integrity, which our customers have come to rely upon. As any manufacturer can attest, free racks are quickly outgrown and simply don’t last which complicates the production process as well as delivery We can see the quality in the Hegla system as it clearly has been substantially made and we now have the ideal solution for all our storage needs. It makes perfect sense to me for anyone with a business or trade counter who deals with bulk stock handling to invest in one of Hegla’s racking systems.”

Brian McDonald, Sales Manager at Hegla UK comments, “It is extremely rewarding to be acknowledged for providing products that not only offer major advantages regarding stock control but also reap huge benefits in terms of cost savings. Window Widgets has carved a niche in the market and we are delighted we could provide the right solution to meet their needs.”

Add new comment