Date: 17 October 2022

The orders, totaling nearly EUR 3 million, are booked in Glaston’s Q3/2022 and Q4/2022 order books and the equipment will be delivered in H1/2023.

Glaston announced in June its plan to establish the production of Automotive pre-processing equipment for standard products at Glaston’s factory in Tianjin, China. The plan is in line with Glaston’s strategic focus to grow its business in China and improve operational efficiency. The aim is to serve customers in the largest automotive market in the world with locally produced machines.

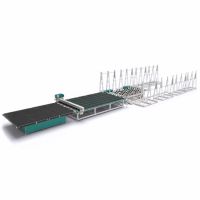

Products sold are Glaston Automotive Technology’s standard CHAMP EVO pre-processing lines to cut, grind and in some cases drill automotive glass like windshields, sidelites, backlites, and increasingly often sunroofs. Especially in the latter, Glaston’s grinding quality is appreciated by the customers.

Since the announcement in June, activities for ramping up the production, enhancing the product-specific production skills and setting up a local automotive supply chain network have proceeded as planned.

Upon completion, Glaston’s factory in Tianjin will be the only Glaston location with production ranging through heat treatment, insulating glass and automotive technologies. These received orders will be the first ones to be delivered from Tianjin in 2023.

“We aim to provide locally fit products with proximity to customers in China. These orders demonstrate the viability of our strategic initiative and that customers perceive locally produced machines well,” says Anders Dahlblom, President and CEO of Glaston Corporation.

Production of Automotive machines in Bützberg, Switzerland will continue to serve Glaston customers outside of China. The Swiss factory will also deliver customized machines to China. The heat treatment machines for the Automotive segment continue to be produced in Tampere, Finland.

600450

600450

Add new comment