Date: 9 December 2024

FREOR is a leader in commercial refrigeration solutions, offering innovative, energy-efficient equipment for retail businesses. Known for their focus on quality and sustainability, FREOR continuously invests in advanced technologies to meet customer expectations and enhance their product offerings.

Challenge: Ensuring Optimal Argon Levels in Refrigeration Equipment

As FREOR began producing insulated glass units for refrigeration equipment, they faced a critical challenge: ensuring the required argon levels within insulating glass units (IGUs). In the refrigeration industry, maintaining proper argon levels is vital for energy efficiency and performance. FREOR needed a reliable solution to uphold their quality standards and meet certification requirements, while addressing market concerns about quality manipulation in energy-related products.

Solution: Sparklike Laser Portable

After evaluating available options, FREOR chose the Sparklike Laser Portable for its industry-leading reputation and technology. The device’s ability to measure argon levels in IGUs without breaking the glass or compromising quality stood out. FREOR emphasized that Sparklike’s commitment to quality aligned with their own, making the decision straightforward. FREOR purchased the device through Idelis, Sparklike’s trusted distributor in the region, ensuring seamless delivery and localized support.

Implementation and Initial Impressions

The implementation of the Sparklike Laser Portable was smooth and aligned with FREOR’s goals. With this device, they can now provide transparent quality data to clients and address any concerns with measurable evidence. This capability not only strengthens their client relationships but also supports their certification processes. FREOR noted that the device is highly professional and requires routine calibration and maintenance to ensure optimal performance.

Benefits: Enhanced Quality Assurance and Customer Trust

- Improved Quality Control: FREOR now ensures the required argon levels in IGUs, supporting their commitment to high-quality refrigeration equipment.

- Client Confidence: By showcasing Sparklike technology to clients, FREOR demonstrates their dedication to transparency and quality assurance.

- Streamlined Certification: The device supports FREOR’s efforts to meet stringent certification requirements for their products.

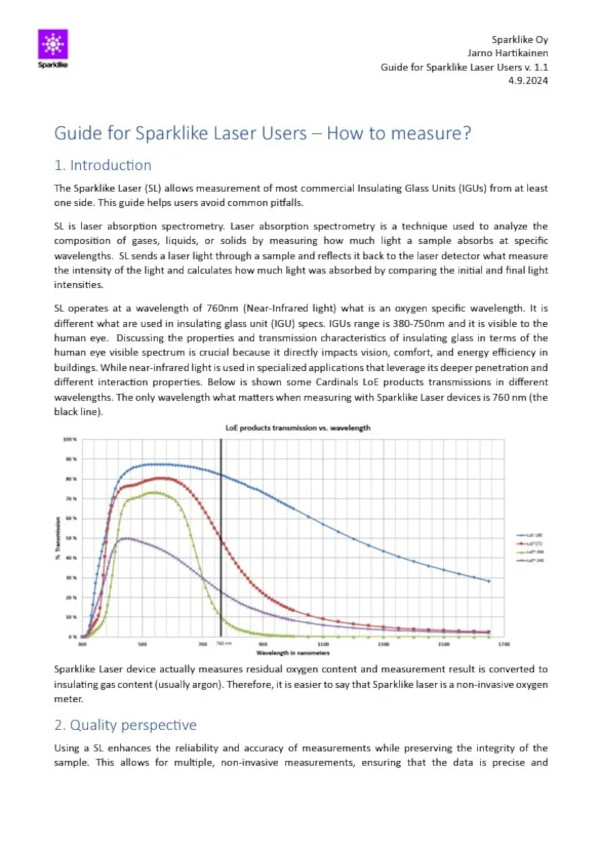

Get better results with your Sparklike Laser device with our guide

Recommendation to Others

Although FREOR is still in the early stages of using the Sparklike Laser Portable, they commend its professional-grade performance. For companies prioritizing quality, the device offers immense value. They advises ensuring timely calibration and maintenance for seamless operation.

Conclusion

FREOR’s adoption of the Sparklike Laser Portable, purchased through Idelis, underscores their commitment to quality and innovation. This collaboration not only enhances their operational capabilities but also reinforces their position as a trusted leader in the refrigeration industry. With Sparklike technology, FREOR is equipped to meet the demands of modern energy-efficient refrigeration solutions.

For more details about Sparklike solution, contact us or our distributors.

600450

600450

Add new comment