Date: 13 December 2023

Emirates Glass LLC, one of the leading organizations in the glass industry and a long-time advocate of Glaston technology, continues its journey of innovation and quality enhancement with the installation of the Glaston Jumbo Series flat glass tempering line featuring Vortex Pro convection technology. This investment marks Emirates Glass’s commitment to delivering top-notch architectural glass solutions to the region and far beyond.

Since its inception in 1997, Emirates Glass has been an integral part of Dubai’s growth and a vital contributor to the region’s architectural landscape. The company has supplied glazing and expertise for many of the most iconic buildings across the city. “We can proudly say that 60% of Dubai is glazed by Emirates Glass,” says Rizwanulla Khan, Executive President of Emirates Glass, who has been associated with the industry for the past four decades.

STAYING AHEAD OF INDUSTRY TRENDS

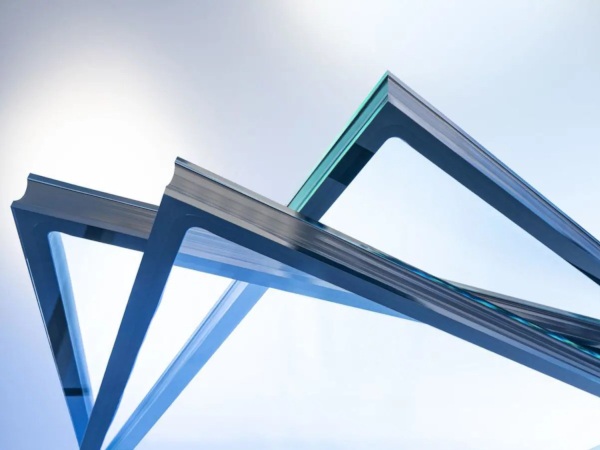

According to Khan, the glass industry in the Middle East has evolved by leaps and bounds in the last 20 years. Gone are the days when it was enough to use uncoated monolithic glasses. Today, the industry is looking for high-performance double- and triple-glazed insulated glass products with the lowest possible emissivity.

“Another trend globally is toward oversized glass panels. Some of the biggest corporations require jumbo-sized glasses for their showrooms. And as a supplier, we are taking the lead,” Khan says.

He also highlights the need for glass products that prioritize sustainability and energy efficiency. Both sustainability and thermal performance are extremely important. But while in Europe the market wants to retain heat, this part of the world aims to retain the cool air. Producing such coatings requires highly sophisticated machinery and technology.

EXPANDING TO JUMBO GLASS WITH A NEW LINE

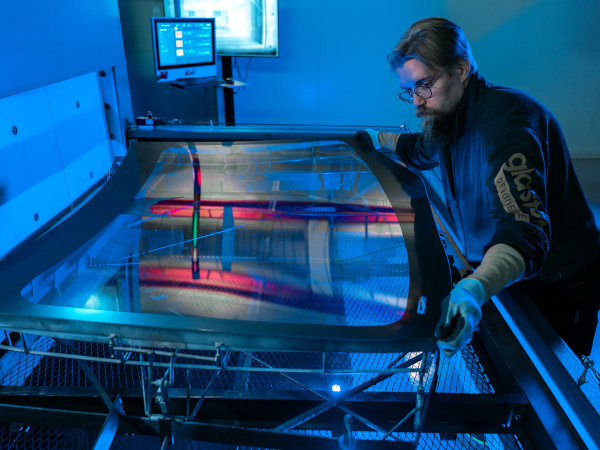

To serve evolving market demands, Emirates Glass has continuously invested in new machinery. Their latest addition is the Glaston Jumbo Series tempering furnace with Vortex Pro convection technology. This new line is capable of processing high-performance coated glass with emissivity levels as low as 0.02 and a maximum glass size of up to 8 m.

This investment complements the company’s two other Glaston tempering lines – the Glaston ProE MAGNUM and Glaston RC200. “Our Glaston MAGNUM machine dates back to 2006. We have been running it round the clock for all these years, and it still operates perfectly. This gave us the confidence that our next machine should be from Glaston, as well,” Khan says.

ACHIEVING REMARKABLE DIFFERENCES

The new tempering line was delivered in November 2020 and has since been a game-changer for Emirates Glass. “We especially appreciate the Glaston Jumbo’s convection control and the Glaston iLooK online quality control for distortion and anisotropy,” Khan says. “Even our customers have noticed a significant improvement in the quality of the glass they receive. We have been able to reach better optical quality and refined aesthetic glass characteristics in part thanks to the anisotropy control. This has elevated overall customer satisfaction and bolstered our reputation for delivering superior glass products.”

The Glaston Jumbo Series has brought about considerable savings, too. “Today, the industry is looking to reduce energy costs in production. Glass processors expect their machinery to efficiently process large volumes of glass. This is exactly what we were able to achieve with the Glaston Jumbo’s effective air and electricity consumption,” he notes.

A LONG HISTORY TOGETHER

Rizwanulla Khan has over 40 years of experience working with Glaston’s equipment in various roles and organizations and knows the company well. “Over the years, Glaston has consistently updated its machine portfolio to align with the latest advancements in glass processing technology,” he says.

“The beauty of working with Glaston that I have always appreciated is that they don’t give up until the customer is satisfied,” Khan says. “Additionally, Glaston’s exceptional after-sales support has been a valuable aspect of our partnership, ensuring that we receive ongoing assistance and maintenance to keep our operations running smoothly.”

VISION FOR THE FUTURE

As Emirates Glass looks ahead, Rizwanulla Khan has a strong vision. With their recent Glaston Jumbo Series furnace investment, Emirates Glass will continue its tradition of excellence, adapting to evolving industry trends and innovating solutions for high-performance architectural glass in the Middle East and far beyond.

“We will continue to put our best efforts into developing energy-efficient glass solutions and special products that will further transform the landscape from regular buildings to pieces of art and architectural ingenuity,” Khan says.

600450

600450

Wow. This expansion in one of your highlights this year. Congratulations!