Date: 2 July 2025

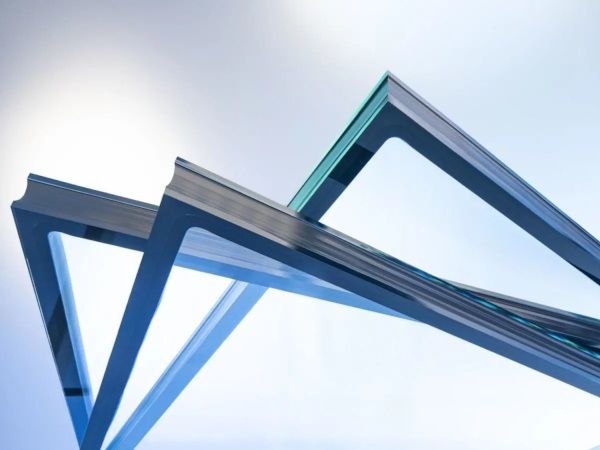

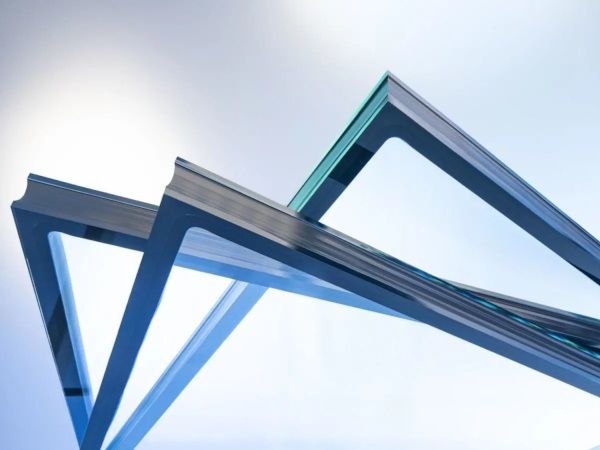

It differs from conventional manufacturing systems by directly applying the Thermo Plastic Spacer TPS® onto the glass plate to produce IG units, multilayer, or solar panels flexibly. It features a new control system and production process sequence for as much as a 15% higher yield.

Thanks to TPS® technology, the highly automated insulating glass production line minimizes the need for personnel, reduces material waste and lowers energy consumption. Together, these result in more optimized processes, significant cost savings and improved efficiency.

More about the technology: https://glaston.net/machine/tps-thermo-plastic-spacer/

600450

600450

Add new comment