Date: 22 March 2018

CE Glass Industries, the successor of Szilánk, has become one of the most significant glass wholesale and glass processing companies in Central and Eastern Europe in the past 29 years. The products can be found in more than 30 countries all over the world by providing a great variety of products and by utilizing only quality commodity products.

CE Glass Industries, the successor of Szilánk, has become one of the most significant glass wholesale and glass processing companies in Central and Eastern Europe in the past 29 years. The products can be found in more than 30 countries all over the world by providing a great variety of products and by utilizing only quality commodity products.

The fundamental goal is to follow and comprehend current technological changes concerning architectural glass industry. It is well-known that CE Glass Industries lays a special emphasis on excellent quality and rapid procedures in order to fulfill the expectations of their customers and partners.

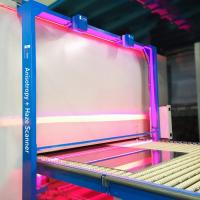

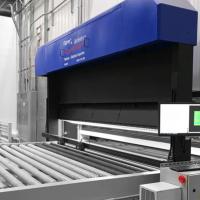

As a consequence, they invested in a LineScanner from Softsolution to enhance efficiency to a great extent. This year, two production lines were installed supplied with LineScan‑ ners in order to guarantee the perfect production of unique insulating glasses.

As a consequence, they invested in a LineScanner from Softsolution to enhance efficiency to a great extent. This year, two production lines were installed supplied with LineScan‑ ners in order to guarantee the perfect production of unique insulating glasses.

The new scanners facilitate the work of their colleagues, what is more, they examine the glasses produced for the partners of CE Glass Industries.

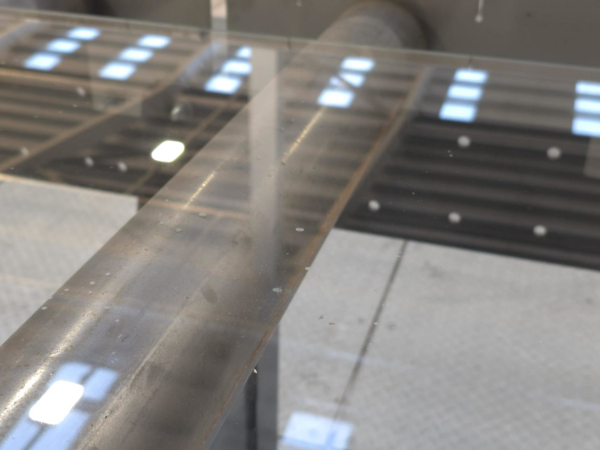

The LineScanner supervises the quality directives required by our partners after the washing phase. After this process, the glass construction is put together according to demands.

The LineScanner does not only examine basic glasses (for instance Float), but it is also able to supervise special glasses like coated glasses or even to check up on tempered or laminated glasses in the interest of perfection in quality. According to their experience, LineScanner performs exceedingly under maximum and continuous load.

The LineScanner does not only examine basic glasses (for instance Float), but it is also able to supervise special glasses like coated glasses or even to check up on tempered or laminated glasses in the interest of perfection in quality. According to their experience, LineScanner performs exceedingly under maximum and continuous load.

“My colleagues have delivered positive opinions about working together with LineScanner since their work has become more effective and much easier due to this brand new technology. As for the future – taking into consideration our experience and the feedback of my colleagues - we decided to work together with Softsolution” says Production Manager Mr. Bede.

Softsolution specialises in automatic glass inspection systems, glass quality assurance systems,electronic image capture and software development in the glass industry for more than 15 years.

Located in Waidhofen/Ybbs, Austria, Softsolution can look back on 400 Line‑ Scanner installations worldwide and guarantees for excellent glass defect inspection systems on the market.

600450

600450

Add new comment